Researchers from MIT have developed a new technique to enable highly detailed multimaterial 3D prints from 3D scanners.

3D prints have long been produced with models generated from 3D scanners, but in almost all cases these prints are a representation of the outer surface of the scanned object only – and then usually only in a single material or color.

This has limited use of 3D printing in many industries. Consider a 3D scan obtained by an MRI or CAT scan device that represents the internal structure of a person’s body. The “external shape” of such a 3D model is not instructive: it’s a box. What is of interest is the differentiated interior where different tissue types make up the structure.

Those structures have been impossible to 3D print, unless they were crudely extracted from the 3D model and printed separately. But then the context of the medical situation is less clear.

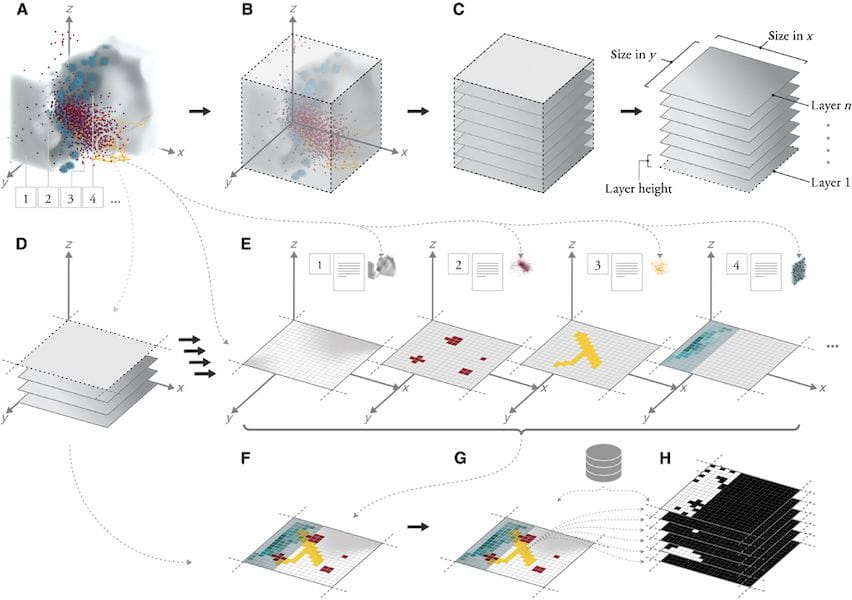

The MIT researchers were able to develop a voxel based analysis technique in which such medical data is transformed into a highly detailed 3D multimaterial 3D model that can then be 3D printed on certain devices.

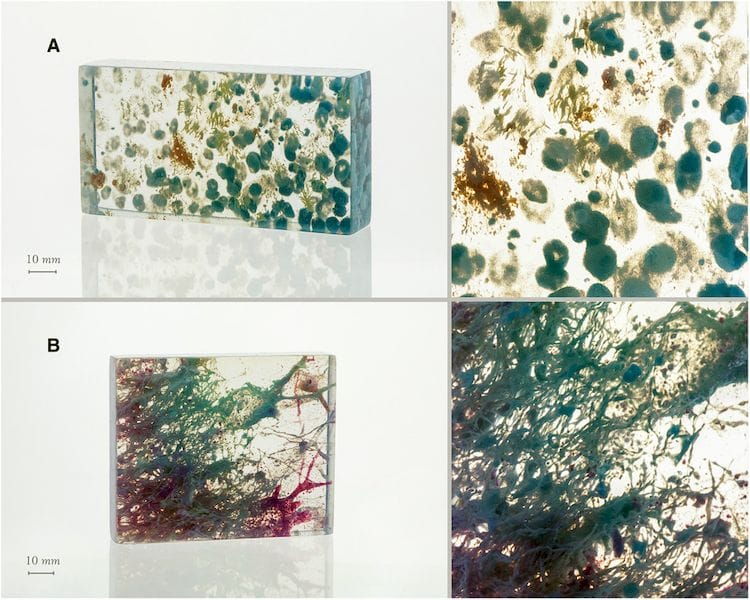

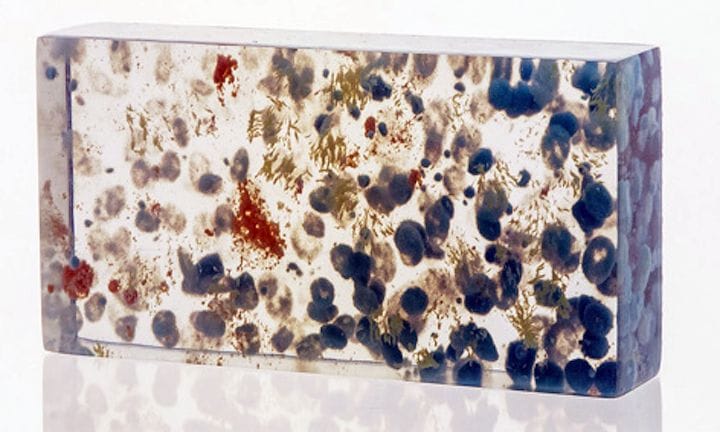

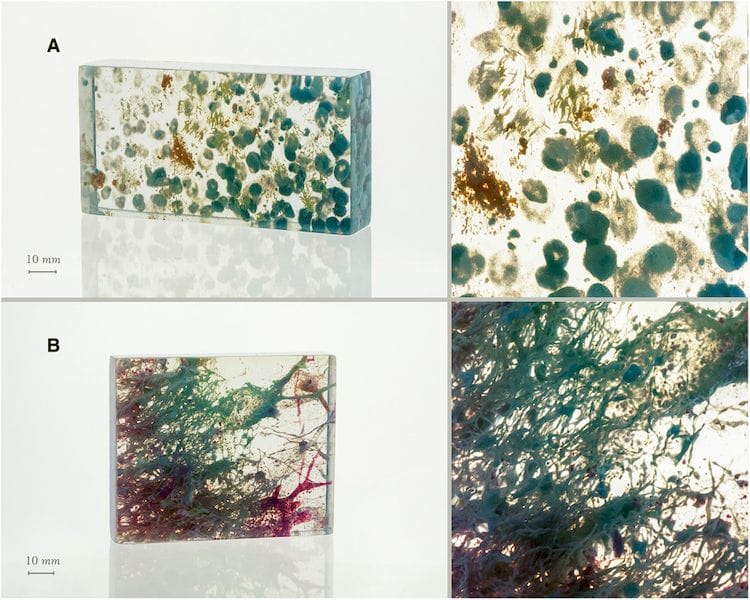

In particular, they used Stratasys’ PolyJet technology, best on the full color J750 device. By mapping the internal structures to different material combinations, and surrounding them with a bulk of transparent material, they can now 3D print actual representations of individual 3D medical scans with tremendous resolution and fidelity.

To do so they transform the incoming point cloud obtained from the medical scanner, likely in DICOM format, and convert it layer by layer into a complex geometry of multimaterial voxels in very high resolution. This does require some thought as to the nature of the structures and an intent for how to perform the mapping, which I presume would vary depending on the exact purpose of the print.

The applications of this are several. The researchers mention:

Presurgical planning, where surgeons can now 3D print a highly detailed model of their surgical target. They’ll be able to see – and touch – it in extreme detail, making the surgical results more reliable, safe and successful.

Learning and Education, where students can examine highly detailed models of body structures that are nearly identical, visually, to the real thing.

Preservation of Artifacts, where unique historical objects can be scanned and preserved, not just from the outside surface, but the interior as well.

I would add one more to this: Artistic Pursuits, where complex 3D scans could be mixed to produce highly unusual artwork, in much the same what that astrophotography uses “scans” of the heavens to create attractive art.

But in a more profound thought, this technology could enable one to 3D scan an entire human and then 3D print a life-size replica – inside and out. It wouldn’t be a working human by any means, but instead a 100% accurate sculpture of the entire human body.

For a working human print we’ll have to wait for several machine upgrades to occur.

Via Science