I’m reading a report on a new concept called “autophage” rockets, and suspect it could use an application of 3D printing.

Rocketry is a science that was more or less static for decades, but recently there have been a number of developments that have spurred new interest. I suspect SpaceX’s low-cost reusable rockets have a lot to do with recent interest.

Rocketry is a precise balance between a number of engineering factors to achieve a result: a payload delivered to a specific altitude at a specific velocity.

The factors involved include weight of fuel, weight of payload, weight of rocket, power of engine and others. The idea is to be as efficient as possible. SpaceX achieves efficiency by the revolutionary concept of reusable rockets, which can be quickly refused and flown again, just like aircraft. You wouldn’t want to trash your 747 after one flight, would you?

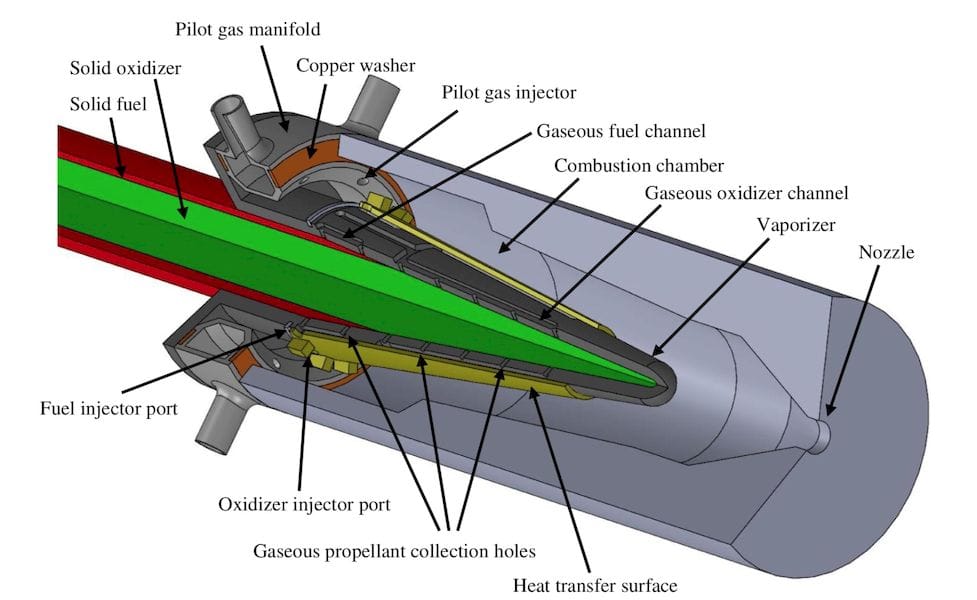

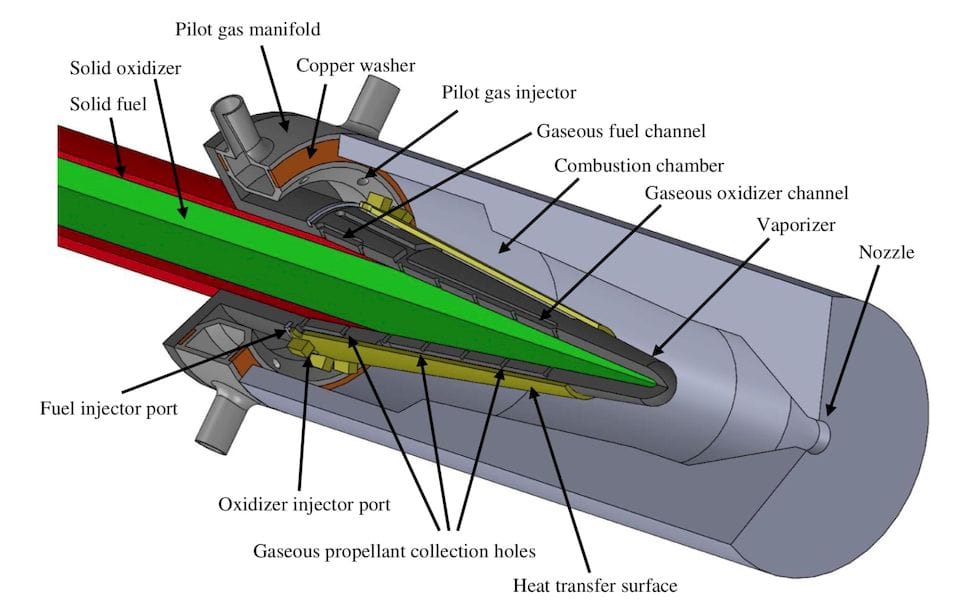

The autophage concept, developed by researchers in Scotland and Ukraine, proposes a way to dramatically change the equation by using the rocket itself as fuel! The engine will burn the structure of the rocket itself. This reduces the weight of the rocket significantly in the equation and increases efficiency.

This appears to be achieved by using solid rocket fuel, as a rigid liquid fuel structure would no out of the question. The solid fuel burns from the surface inwards, eventually being discarded.

But here’s the problem: rockets often require different flight profiles, where the engines must be throttled up or down depending on the state of the aerodynamic pressure. In many conventional rockets this is done by simply cranking down (or up) the valves on the liquid fuel motors. But that’s not possible on solid fuels. Once you light them, they burn until done.

One idea to overcome this is to produce a burnable solid fuel shape in different shapes as you go deeper into the structure. As the burn layer moves through the structure, it could encounter different surface areas that could speed up or slow down the rate of burn.

But this might require a complex shape that would burn in a way that precisely matches the required flight profile.

How could such a structure be produced?

I suspect this could be a great application for 3D printing, which is well known for its ability to produce arbitrary shapes, including the potentially complex shapes required for custom solid fuel burn profiles.

I do know at least one company is developing 3D printing technology for solid fuel production, but doing so for an autophage rocket would be at quite another level: the rocket would not only have to burn with the right profile, but also maintain structural integrity throughout. Some sophisticated design software would be required.

But if done, then we could see a new family of self-consuming rockets produced.

Will they be more efficient than SpaceX’s reusable fleet? I’m not sure they could, but there are many niches within the rocket industry that they might be able to occupy where SpaceX and other reusable approaches don’t offer solutions.