Authentise mentioned in their recent newsletter a relationship with EOS equipment, suggesting a significant move.

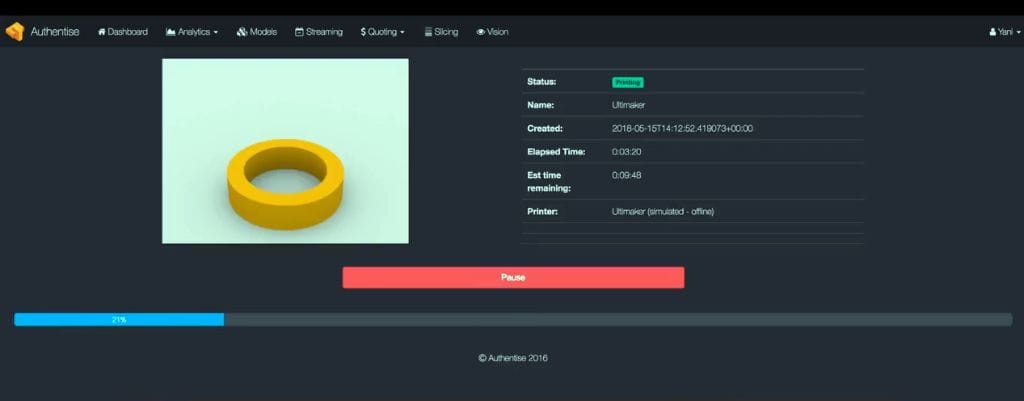

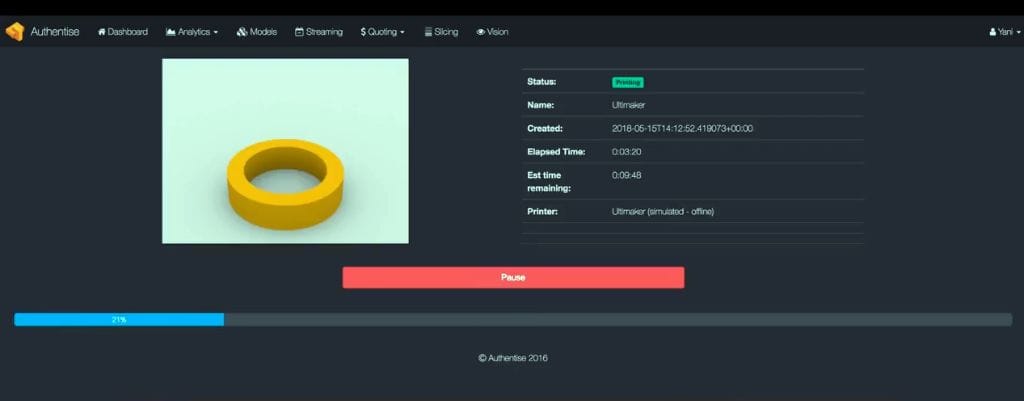

Authentise is one of several companies hoping to capitalize on the concept of 3D print streaming. In this mode the 3D printer is controlled remotely through a cloud or network system, rather than operating the machine directly itself or by local PC control.

There are multiple advantages in doing so, although there are also a few disadvantages.

On the positive side, moving control to a cloud environment opens up the possibility of bringing significant software power to the problem, far more than could ever be delivered by local firmware. Cloud software can also be updated far more rapidly and for all participants instantly.

Negatively, however, controlling a 3D printer via network and/or cloud does introduce the possibility of print failure if the network connection is disrupted. While generally reliable in most situations these days, it’s still a risk essentially missing in local control scenarios.

I believe the advantages far outweigh the disadvantages.

One of the implications of the cloud approach is to enable more secure protection for 3D intellectual property. Local 3D printing by definition means control over the 3D content is provided to whoever is controlling the printer. That’s not good for those wishing to retain ownership of a 3D design. However, with streaming it is possible to deliver the 3D content to the 3D printer without having it stored locally in any way.

That’s one of the key features Authentise offers to their clients, but there’s a challenge: If 3D content owners are to deploy their secured content widely, then adoption of these protocols must also be widespread.

Authentise and similar services have focused on commonly used open source 3D printer platforms typically used on small desktop 3D printers. While this certainly works, it doesn’t include the large-scale commercial 3D printers.

And that’s a problem, because that’s where the money is in 3D printing these days.

Now Authentise announced they’ve been able to connect with EOS 3D printers, which are well known and used by many industrial operations. EOS equipment includes both thermoplastic and metal systems, often used to produce final production parts, particularly in aerospace and automotive industries.

Authentise says:

Authentise has a history of developing solutions that enable the users to do more with their equipment. Now, building on our work in streaming and with companies like Lowe’s and Stratasys, we are starting to move on to direct control of machines. EOS is committed, and we can push directly information into their 3D printers. Initially, we are rolling out these features to EOS printers, but there will be many more to come.

They say their new EOS integration will provide these capabilities:

- Nesting can be more efficient due to a more direct and data-rich approach in dealing with orders.

- Setup can be more automated, by giving our platform the power to schedule certain operations without user’s input.

- Quoting can be more accurate.

- Set up each machine, generate and send the toolpaths remotely into the printers.

- and much more!

You can get a hint here of how the power of cloud software can be significant.

At this point it appears their EOS integration is in test mode, but they are inviting EOS users to participate as beta testers. While that might not be appropriate for EOS operators making production parts, I suspect there are plenty of EOS clients that are in a position to try this out.

This move from Authentise supports the idea that they, like most companies in the 3D printing space, are moving closer to industrial clients. By integrating with EOS they take a strong step in that direction, and if they add more integrations with production-level equipment, they could be on to something.

If you are an EOS client, you might want to contact Authentise to find out more.

Via Authentise