3D Systems seems to be building a bit of an ecosystem surrounding their medical venture.

Medical applications is one of the company’s key money makers in recent years and it makes sense to enhance it further. While the company has long been 3D printing dental aligners, today their work in the medical industry is vastly larger. They’ve put together hardware, software, partnerships and more to provide a number of very specific solutions for different areas of the medical industry.

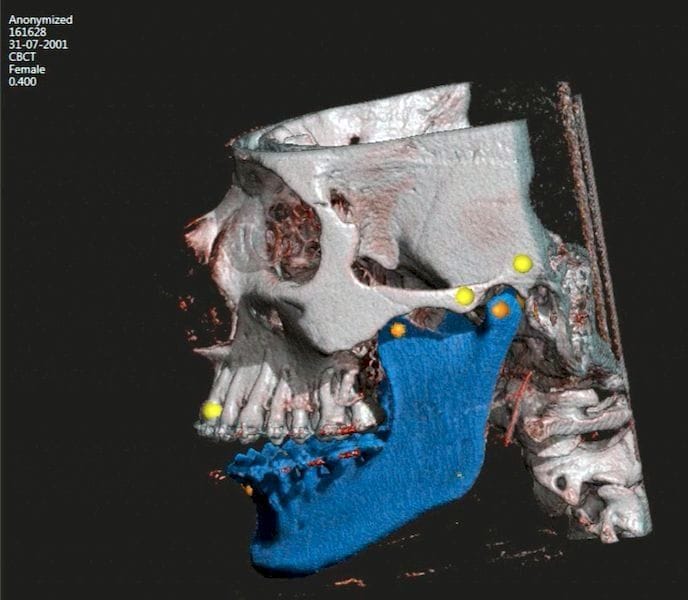

Their most recent enhancement is interesting; it’s a kind of specialized 3D print service designed for anatomical 3D models. They’re able to produce anatomical 3D models in a variety of materials, including full color, transparent and opaque.

When you visit their site it first appears to be a simple 3D print service like any other: upload your 3D model, get a quote and request a print. Will be delivered in five days.

Almost every 3D print service will do pretty much the same things.

But there’s a bit more to the story here.

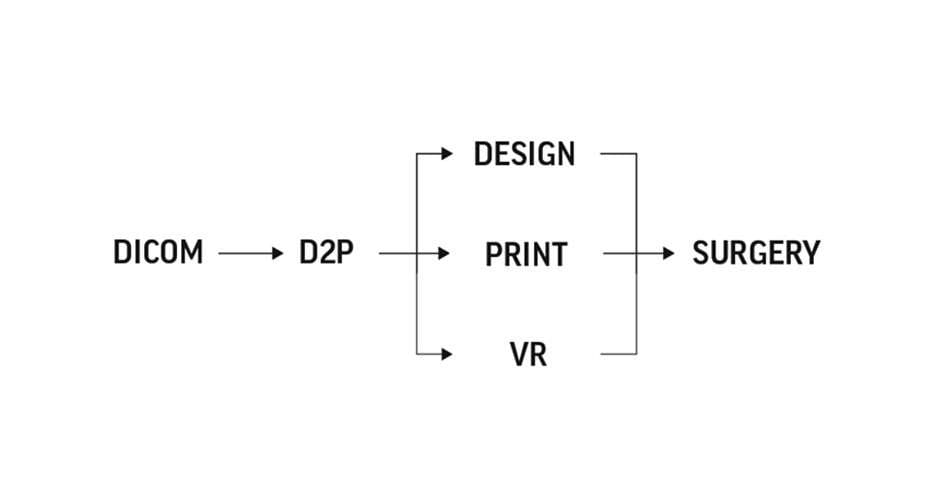

3D Systems also has an interesting piece of software called “D2P”, which is short for “DICOM to PRINT”. DICOM is a widely used 3D format for medical imaging, and this includes 3D data obtained from 3D-capable medical imaging systems like MRIs, CT Scanners and more.

It’s a tricky business transforming DICOM data into printable 3D models, and thus it hasn’t been done particularly frequently. However, the D2P software automates much of the work and thus enables quick creation of suitable 3D models. Suitable for 3D printing, that is.

And now we look back at the new Anatomical 3D print service and notice that 3D Systems has integrated D2P functionality so that there is now a mostly seamless experience between the medical imaging system and the opportunity to 3D print the result.

This is hugely important for the medical industry because this workflow should eliminate some of the barriers encountered by medical imaging technicians and other medical professionals seeking 3D representations of anatomical situations. Surgeons, for example, might want to see – and touch – a 3D model of a surgery site to visually rehearse the steps being undertaken.

Now they should be more easily able to make a request for the 3D print using the new 3D Systems workflow.

For 3D Systems this can only be good news, as the diminishing of barriers to 3D printing implies that more 3D printing will take place on their equipment. While 3D Systems sells many units to customers, they themselves are also a big client, as they operate significant 3D print services based on their own gear. This workflow will help keep that equipment busy.

Via 3D Systems