The newly fully enclosed Titan Robotics Atlas large-format 3D printer

The newly fully enclosed Titan Robotics Atlas large-format 3D printer

When we first encountered Titan Robotics some years ago, their machine was quite large.

At the time we met Titan Robotics, I believe there were only two people on staff. But now the company has expanded to around 15 people, and I expect them to grow significantly given the state of their latest machine.

Their 3D printer is still a very large machine, but founder and engineer Clay Guillory continues to tweak and improve his company’s equipment. And their recent changes are quite dramatic.

The machine is still the “Atlas”, but it is so different than the machine we saw three years ago. This machine is entirely enclosed and heated, and is now suitable for 3D printing many types of 3D print materials, including ULTEM:

A “small” 3D print in ULTEM made by Titan Robotics

A “small” 3D print in ULTEM made by Titan Robotics

While this is a somewhat small print, we’re told they are very “close” to achieving large-scale ULTEM prints. We’ve seen evidence that they are working on enabling a wide variety of other unusual materials for the Atlas, including flexible TPU.

The Atlas is now fully capable of using pellets as material instead of the more typical filament. Pellets are considerably less expensive than filament, and this is utterly important when performing large sized 3D prints as one might do on the Atlas, which has a print volume of up to 1067 x 1220mm, one of the largest thermoplastic 3D printers you can acquire.

But the current Atlas includes some features well beyond those.

New Yaskawa equipment is used in Titan Robotic’s Atlas 3D printer

New Yaskawa equipment is used in Titan Robotic’s Atlas 3D printer

The big move is the partnership with Yaskawa, a notable manufacturer of high speed automation control systems. Their servo-motor systems are now on the Atlas and provide considerable advantages:

- The closed loop system means the machine “knows” where it is at all times, for increased reliability

- The motion system can move the toolhead at up to 5G’s!

- Printing can be as fast as 350mm/second, far faster than the typical 60mm/second found on most machines

- Dynamic adjustments based on realtime automation feedback (e.g. if a motor has too much torque, the system automatically adjusts for that)

- The Atlas can now detect “bumps” using realtime feedback that are ignored by most machines, and stop the print

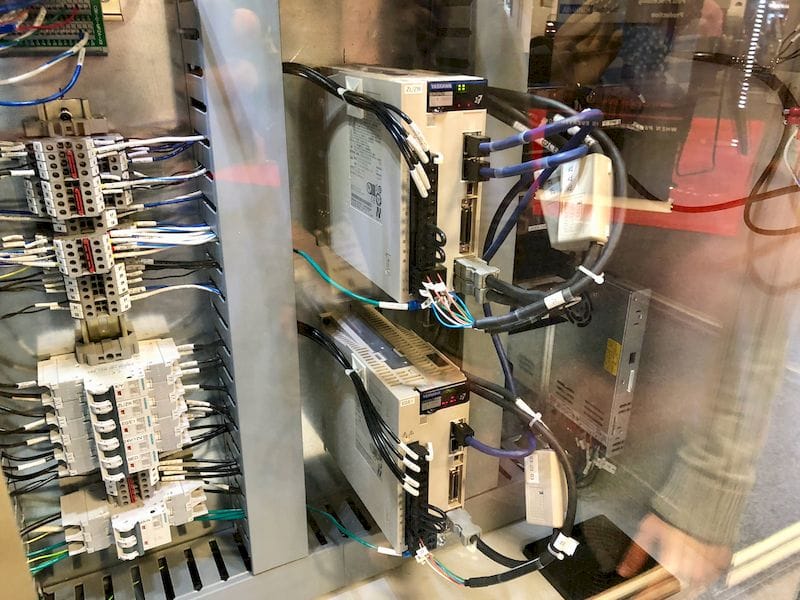

New Yaskawa controllers installed inside one of Titan Robotic’s Atlas large format 3D printers

New Yaskawa controllers installed inside one of Titan Robotic’s Atlas large format 3D printers

These are significant benefits I don’t believe are found on any other 3D printer, and especially on large-format devices such as the Atlas.

We’re told that prior buyers of Titan Robotics Atlas machines cannot practically upgrade to the new automation system, as there would be a very significant wiring change required, rendering that move financially infeasible.

But new buyers can obtain an Atlas machine for USD$80-120K, depending on options selected.

Via Titan Robotics