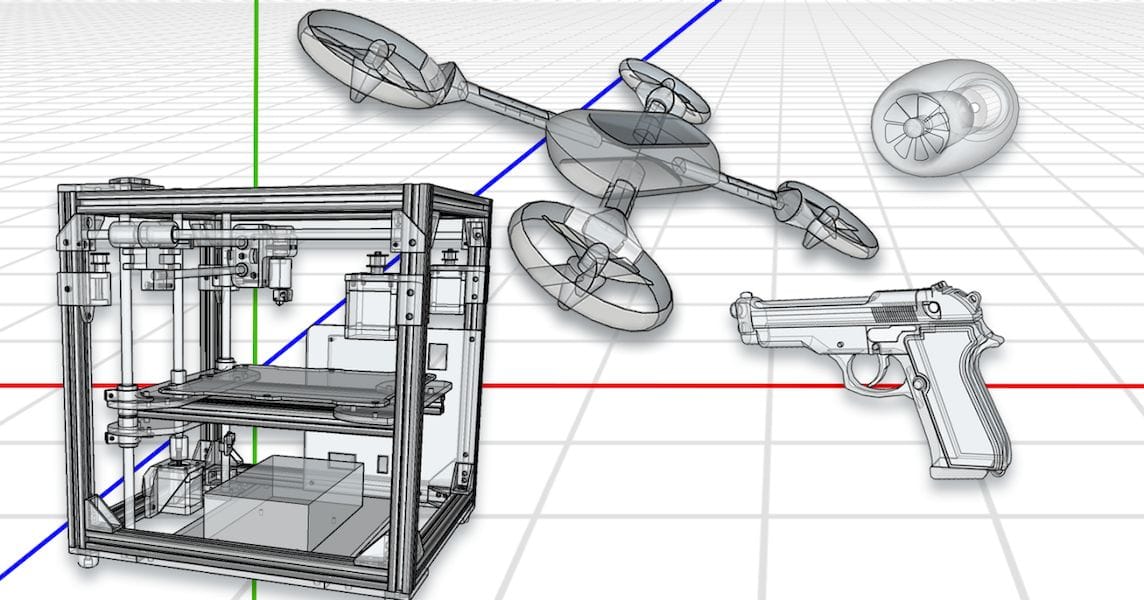

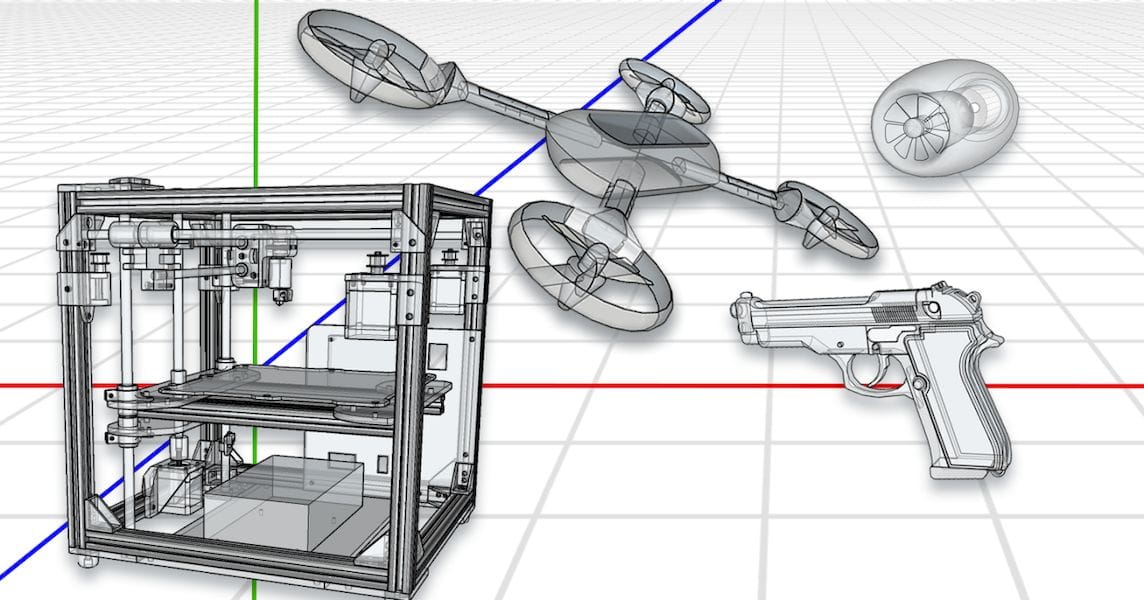

RAND Corporation’s views on 3D printing seem a lot more worrisome than they should be.

RAND Corporation is a well-known US non-profit research and analysis organization who have published many groundbreaking studies in the past. Today I’m looking at a post, entitled “Four Ways 3D Printing May Threaten Security” on their blog that describes their concerns about the use of 3D printing from a security point of view.

Let’s look at each of their points in order:

Hackers Could Use Printers to Cause Real-World Damage: RAND proposes that when critical parts are manufactured on 3D printers it may be possible for hackers to covertly alter the design file so that the manufactured part contains a flaw. And it could be a flaw that only “engages” when the part is being used at a critical point in its application lifecycle, for example, when a valve reaches a particular temperature and fails.

Printers Could Enable New Criminal and Security Threats: RAND suggests that “the bad guys” could make use of 3D printing to produce their own weapons without the supervision of the usual authorities.

New Manufacturing Capabilities Could Endanger Jobs: RAND’s position that 3D printers are slowly becoming “Factories in a box”, and thus could take away manufacturing jobs that would otherwise be done manually.

Printers Could Change the Rules in International Affairs: RAND points out that international sanctions may be bypassed because those officially prevented from using certain products just might be able to 3D print their own versions and thus bypass the sanctions.

I agree that these may be superficially true, but I think there is much more to the story.

In several of these scenarios one merely needs to take proper care of the design files. 3D printers print what they are told to print. They are not magic; they are like computers: garbage in, garbage out.

In today’s world most reputable corporations take steps to ensure the security and robustness of their data, simply because their operations would fail otherwise if hackers could disturb them.

Surprise: 3D design files are also data! They can be secured in many ways already well-known in the IT industry. However, I suspect that in many workshops the 3D design files are sometimes considered “a thing”, like the object they represent, rather than “valuable data”.

Certainly hacks do occur in companies’ data, in spite of their best efforts. But what is one to do? Essentially this is the cost of doing business today and it is no different in 3D printing.

Note that 3D design files are used by almost all other modern manufacturing equipment, like CNC mills, for example, so this problem is most certainly not confined only to 3D printing and is something that would affect manufacturing of almost everything with most making devices.

To that point, the “bad guys” also have access to CNC equipment, and likely have better access to them than they do with 3D printers, particularly for the more useful metal applications. Saying that 3D printers introduce risk here is not true; the risk is largely already present and is only slightly changed with 3D printing technology.

Finally, the suggestion that 3D printers may destroy jobs could indeed be true. But again the same can be said of robotics in general. We are in a world that is slowly being robotized, in both physical and mental tasks. No area is “safe” from this phenomenon. While something may be considered non-automatable today, the line of automation slowly advances, gradually consuming manual efforts one-by-one.

Years from now it’s conceivable the majority of “work” will be automated by robots and AI techniques. Some say we will simply move on to “new kinds of jobs” as has been done in the past. However, I think this is quite different, in that the increasingly adept robotic and AI approaches will swiftly be used to automate those, too, far faster than new jobs can be invented.

I don’t believe there is a technical solution for this scenario; instead it likely has to be a radically different societal and economic solution of a design I have yet to see.

Via RAND