Last week Stratasys announced some new 3D printers.

Each of the machines are an evolution of prior products, but offer value to purchasers.

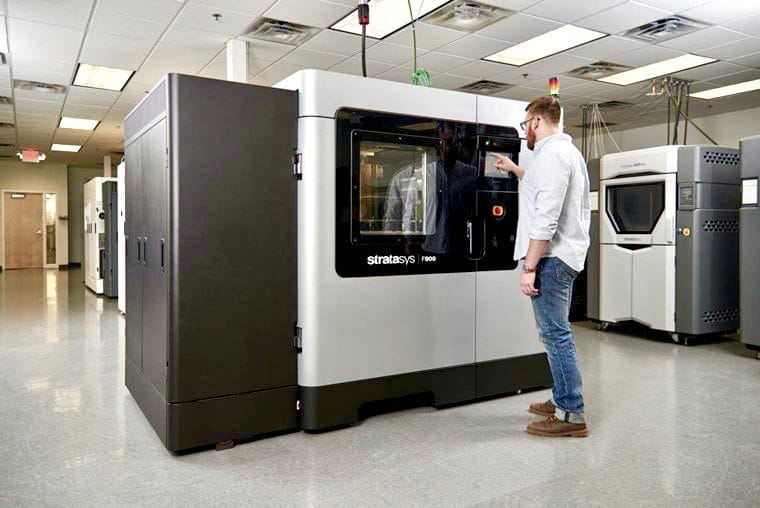

The first is the F900 Production 3D Printer, which is based on their previous largest machine, the Fortus 900mc. The machine has the same build volume and performance standards, but with some extras.

One extra is that the machine is much more compatible with manufacturing environments. It includes an MTConnect interface, which if you don’t know, is a “free, open standard for the factory”. This standard enables the new F900’s to more easily participate in an integrated factory environment and takes Stratasys’ equipment a bit closer to Factory 4.0 state.

The F900 is actually available in two additional variations, each specialized for different applications.

One is the “Stratasys F900 Aircraft Interiors Certification Solution”, which is clearly similar to Stratasys’ previous offerings, which enable use of the equipment to produce components for, obviously, aircraft interiors. The key here is that the system includes the required elements for certification in such environments, including a method for part traceability. While not substantially different from the base F900, this packaging option makes it very easy for aircraft manufacturers to step right into use of 3D printing, at least for certain types of parts.

Another is the F900 PRO, which appears to be again a stock F900 system, but one enabled to use the popular ULTEM high temperature material.

All of these machines can also make use of Stratasys’ new Nylon 12 Carbon Fiber material, which exhibits great strength. Note that this is simply chopped carbon fiber, not continuous strands of carbon fiber, which would be much stronger.

The F900 boasts Stratasys’ largest build volume for extrusion-style 3D printing, but if you need to print in the Nylon 12 CF material, you don’t need to purchase such a large machine. Instead, Stratasys will also offer later this year a specialized 3D printer for carbon fiber materials, the Fortus 380CF.

These announcements maintain Stratasys’ goal of moving towards production environments, as their original market of prototyping is getting a bit busy with numerous competitors emerging after patents expired. These competitors now offer access to many different materials, including Nylon carbon fiber filaments, which perhaps explains one reason why Stratasys decided to offer this powerful material.

Via Stratasys