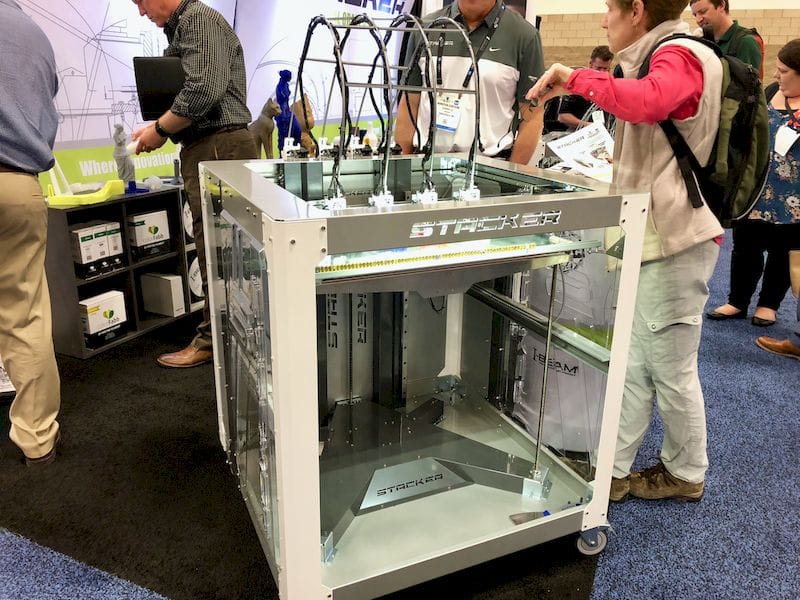

We got a shock when looking at Stacker’s latest machine.

Their new XL machine sports what they call “combo” extruders, which have an ability we have not seen elsewhere.

But first a bit of background. In the world of filament 3D printing, there are two methods of delivering filament to the hot end of the machine via an extruder. One is the so-called “Direct” approach, where a motor pulls the filament right into the adjacent hot end. The other approach is the Bowden style, where a distant extruder motor pushes a length of filament through a tube into a hot end.

There are advantages and disadvantages to each approach, and you’ll see 3D printers adopt one or the other for various reasons. We explained the difference between the two approaches in some detail here.

Which approach does Stacker’s Combo Drive use? It turns out it uses BOTH!

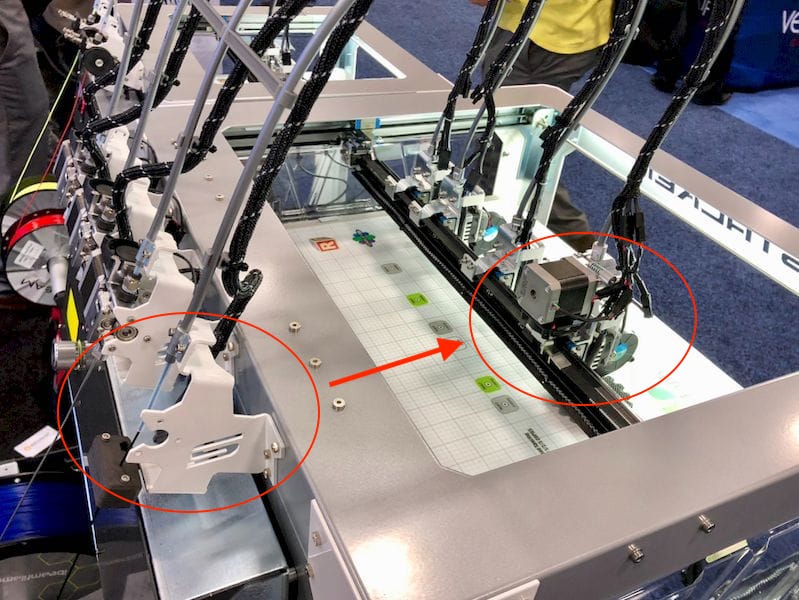

In the image here you can see an array of Stacker’s extruders, which they use to 3D print multiple parts in parallel, also a great feature. But one of those extruders is in a different position.

The extruders at the rear are Bowden; they are pushing filament through tubes towards the lightweight hot end. The extruder closest to us is a Direct extruder, mounted on the hot end and is pulling filament into the toolhead.

Evidently the Combo Drive extruders can be quickly demounted and remounted in the other mode. There’s a couple of bolts to do so, but we’re told the switch can be done in only eight seconds!

This is a significant development, as it means Stacker users need no longer be concerned about the disadvantages of either approach. If there’s an issue, just swap the extruder into the other mode.

For example, flexible TPU material is notoriously difficult to use in Bowden-style systems, because it’s hard to push a flexible material any length without causing a jam. Imagine trying to push a string through a tube – it just doesn’t work.

In Stacker’s case, you can simply pop off and remount the extruder in Direct mode and you can immediately print TPU effectively at up to 50mm/second. Later you can reverse the procedure to lower the weight of the toolhead and speed up printing.

These servo motor-based extruders are truly a wonder; I’ve not seen this approach on any other 3D printer, and perhaps it should be a standard feature.

Evidently this approach is proving quite popular, as we were informed that Stacker now has a 60 day backlog for equipment orders for the USD$25K XL machine. They’ve apparently sold dozens of machines since December.

If a machine has the right features, it is going to sell many more units.

Via Stacker