Research from the Karlsruher Institut für Technologie suggests the possibility of cold 3D printed glass objects.

Glass is a highly valued engineering material for a number of reasons. While consumers may feel its a rather fragile substance, it does exhibit heat resistance, chemical resistance and is often optically transparent. Depending on the application, glass could be the best material for the job.

But 3D printed glass equipment is not something you can easily buy off the shelf. I’ve seen a couple of experiments in 3D printed glass, which tend to be complex systems involving superheated thick paste-like glass being extruded through a very coarse nozzle at slow speeds. The resulting objects were quite limited in geometry as glass tends to slump if overhangs are attempted, and the extrusion width was too wide to allow for finely detailed objects.

That’s not good news for those hoping to use glass. But the new research may point to a way that glass material could be effectively used in 3D printing applications.

Their process is actually a familiar one: mix a liquid photopolymer resin with other material. In this case, the other material is glass particles. The researchers created a 60 to 40% ratio of glass to polymer.

This polymer was then exposed to UV light, whereupon it solidified. The resulting object was, as one would expect, only 60% glass, which they call a “glassomer”. They say:

This “Glassomer” can be milled, turned, laser-machined or pro-cessed in CNC machines just like a conventional polymer.

However, a post processing step places the object in a 500C oven where the remaining polymer is burned out, leaving a near-pure glass object.

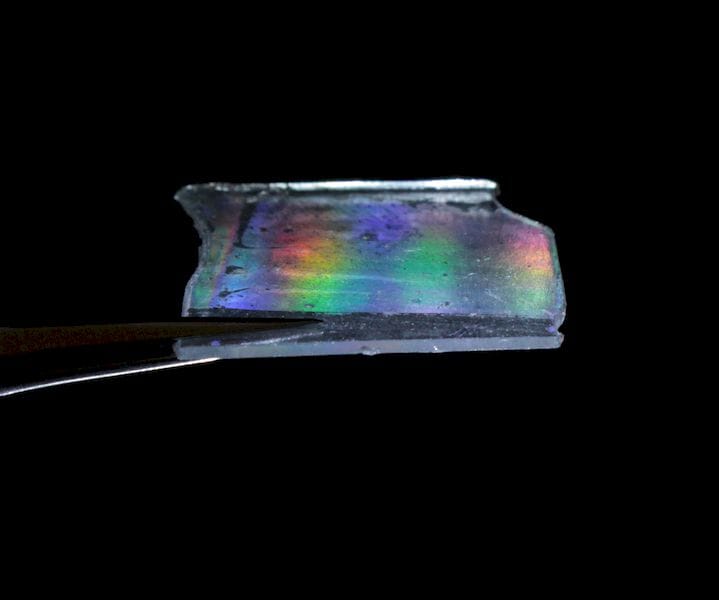

This allows the process to create usable optical lenses.

What they don’t say is whether this material could be used in 3D printers, which, by mere coincidence use liquid polymers and UV light to solidify objects.

It seems to me that this glassomer material could most certainly be used in a number of resin-based 3D printers, given some experimentation with printing parameters. Why wouldn’t this work?

And if it does, then one could consider using the post-processing step to create fully glass objects that are sufficiently pure to be used in optical applications.

Someone should get on this, if there isn’t anyone already doing so.