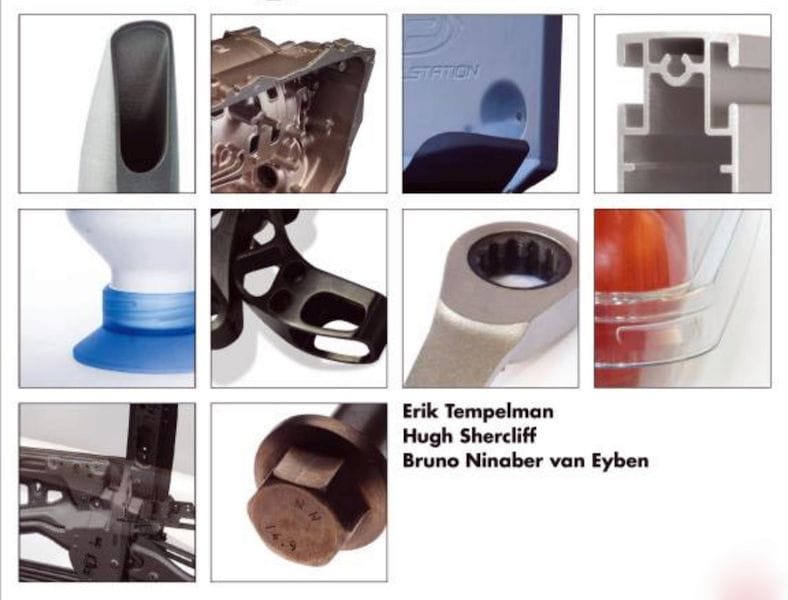

This week’s selection is “Manufacturing and Design: Understanding the Principles of How Things Are Made” by Erik Tempelman.

This book is a comprehensive look at the relationship between design and manufacturing, which, although quite different disciplines, are tightly interrelated: a design must ultimately be manufacturable, or you won’t have a product.

That is the end goal: a manufactured product, and while the process begins with a design that attempts to meet some functional and aesthetic requirements, that is definitely not the end of the design process.

Manufacturing an object is governed by the constraints of the specific making processes to be involved, and this is where the relationship starts. Often a design must be remade in order to be more compatible with the constraints of a making process, and sometimes this is done through many iterations.

But what are those limitations and how should one go about solving this dilemma? That’s what “Manufacturing and Design” is all about.

This book reviews the role of the designer with respect to manufacturing, and reviews multiple common making processes, including:

- Casting

- Sheet metal forming

- Metal extrusion

- Machining

- Injection molding

- Thermoforming

- Resin transfer molding

- Joining and assembly

- Thixomolding

- Sintering

- Laser cutting

- Rotational molding

- Thermoplastic extrusion

- Compression molding

- Glass blowing

- Ceramic slip casting

- Heat treatments

- Coating and Painting

And of course, Additive Manufacturing.

Due to the differences in skills, design and manufacturing are effectively two unique disciplines, yet they cannot truly exist without each other.

This book brings both together in a way that should make the sometimes challenging interactions between design and manufacturing a bit easier.

Via Amazon