3D Platform makes them big, and this is no exception.

They’ve pre-released information about a new device they’ve named the “Workcenter 500”. It’s a large format 3D printer, large even for 3D Platform, who have made their mark by producing devices with build volume of around a full meter on an axis.

Their foray into the world of large-format 3D printers a few years ago proved quite successful, as they, along with a very few other competitors, discovered there is indeed a profitable market for larger format 3D printing. Typically manufacturers use them to produce full-size prototypes in PLA material as test cases before committing to full manufacturing.

The reason for this profitability is simply that their customers would spend inordinate amounts of money producing huge prototypes using conventional approaches, such as milling. While some may suggest the price of the large format 3D printers are high, they are actually seen as small and quite affordable by manufacturers who are used to spending a great deal on prototyping.

But back to the new Workcenter 500. It’s a table-like device, similar to 3D Platform’s previous equipment, but with two very attractive changes.

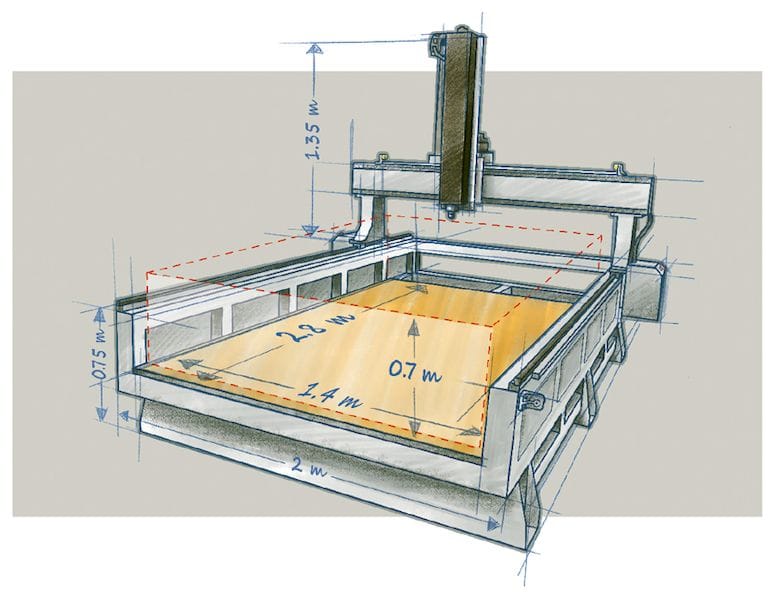

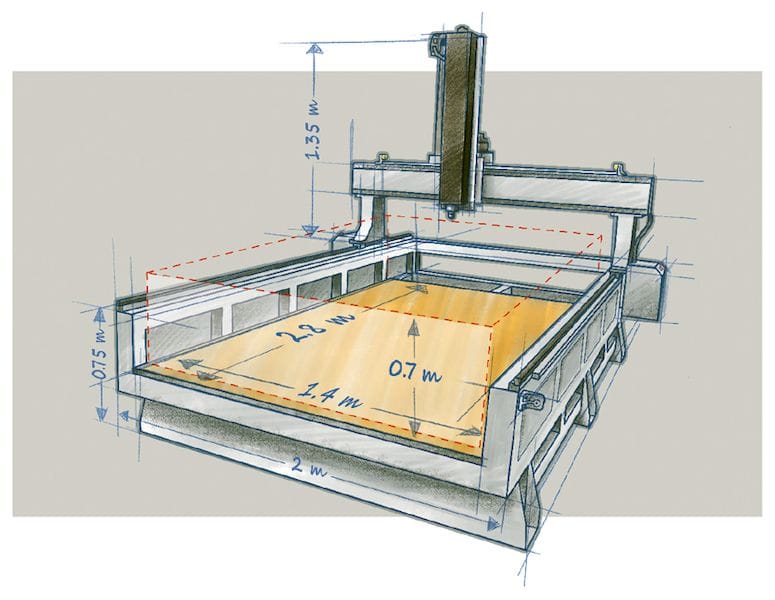

First, it’s a lot bigger. While their previous machines were around 1000mm on the long axis, the new Workcenter 500 boasts a truly massive 1400 x 2800 x 700mm build volume.

It’s hard to comprehend how incredibly large this volume is. To put the size in perspective, the volume is equivalent to approximately 270 Ultimaker 2’s.

Now you’re probably thinking, “another bigger printer that will take even longer to complete a big print”.

If so, you’d be wrong.

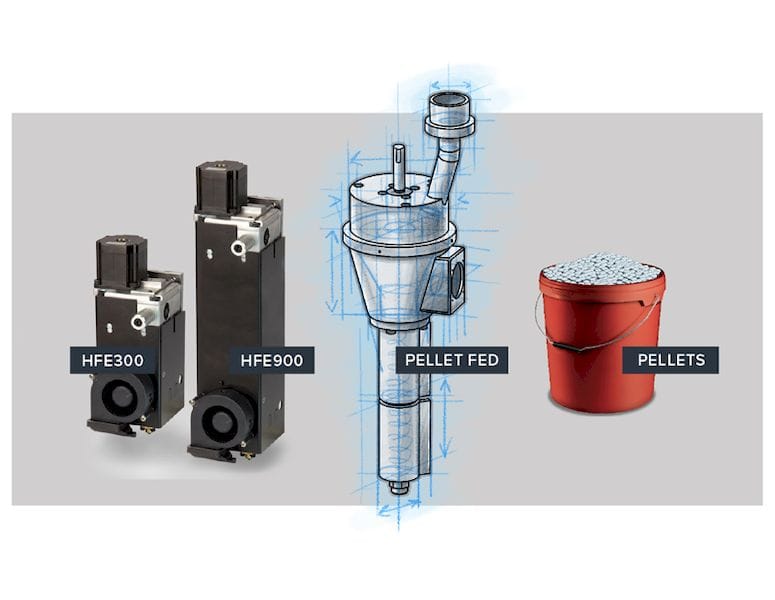

3D Platform has included another very important addition to the Workcenter 500: a fast extruder. We’ve previously seen 3D Platform’s super-fast extruders, but there is yet another twist on the Workcenter 500: it includes a pellet feeder!

This means that not only will your large prints be completed relatively rapidly, you can do so with less cost by using cheap pellets instead of pricey filament.

Pellets also provide an opportunity to mix colors and perhaps even composite materials.

3D Platform says that the WorkCenter 500 will be able to deposit more than 7.5kg of material per hour. That’s an absurd amount of material. Again, to put this in perspective, that’s like using up a an entire 750g spool every SIX MINUTES! Were you buying such spools of filament for USD$25 each, that means this machine could cost USD$250 per hour, or USD$6,000 per day to operate. It’s no wonder they included the pellet option, which should bring down the price dramatically.

3D Platform says the Workcenter 500 can come equipped with either filament or pellet extruders, or both!

Finally, they say the price of the device will be reasonable, suggesting it will be less than USD$200K. That is a healthy chunk of cash, but it is certainly a lot less than some competing systems priced at USD$500K and above. On the other hand, the WorkCenter 500 will be printing only in PLA, I suspect.

It’s not clear when the WorkCenter 500 will be available for purchase, but in the interim if you really, really want to try one, 3D Platform is accepting applications for entering a beta test program in which you’d receive a machine before official release.

Via 3D Platform