Senvol has contracted with the US Navy to develop very powerful 3D printing software.

The New York-based company has provided the industry with a wealth of information on 3D printing materials and machines for several years. Their highly detailed and very extensive databases are able to quickly identify the right material for almost any engineering endeavor.

But now they’ve announced a rather interesting arrangement with the US Navy. They explain:

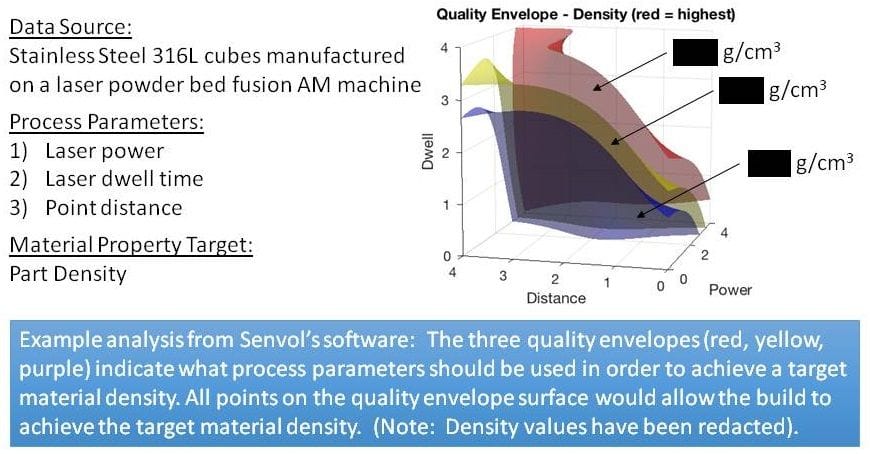

Senvol has publicly announced that it is developing data-driven machine learning additive manufacturing (AM) software for the U.S. Navy’s Office of Naval Research (ONR). Senvol’s software analyzes the relationships between AM process parameters and material performance.

ONR’s goal is to use Senvol’s software to assist in developing statistically substantiated material properties in hopes of reducing conventional material characterization and testing that is needed to develop design allowables.

This, to me, is a bit of a breakthrough, as the correct links between material and machine has simply not existed in mass form previously.

Many 3D printer companies do provide such information on an extremely limited basis: to encourage quality 3D prints, they will recommend a particular vendor’s material and provide a matching print profile.

That’s great for users of that 3D printer who happen to need that particular material. But what about any of the other infinite combinations? Up to now there has been really no way to attack this problem other than laborious trial and error.

Now it appears that Senvol wants to tackle this problem though a machine learning approach that could bypass the trial and error stage to get approximations that surely will be far better than guessing, which is what everyone must do today.

But how would this work, exactly? Senvol provides some clues:

A modularized ICME (integrated computational materials engineering) probabilistic framework for AM data serves as the foundation for Senvol’s software. In this framework, AM data is categorized into four modules: Process parameters, process signatures, material properties, and mechanical performance. The software being developed is powered by an algorithm that quantifies the relationships between the four modules. The algorithm is AM material, machine, and process agnostic.

One question I wondered about is whether this research for the US Navy will ever make its way into public industry. Could this technology be considered of strategic vital importance by the US Navy and thus be kept close? Or will it eventually be made available by Senvol to anyone?

The answer is very clear from Senvol:

The software under development will be made commercially available to any company looking to qualify AM parts.

In fact, it seems they’re looking to contact anyone who’s interested in participating in a beta program.

If that’s you, give them a call.

Via Senvol