LPW announced one interesting new metal powder suitable for 3D printing, and there may be more on the way.

The new material is Tantalum, one of the class of so-called refractory metals. These are elements that exhibit very high heat and wear resistance, all with melting points above 2400C.

The other refractory metals on the periodic table include Molybdenum, Rhenium, Niobium and Tungsten. Tantalum is a somewhat rarer item in the 3D metal printing space.

It’s melting point is slightly less than Tungsten’s 3422C at “only” 3017C. These are very high temperatures, and if using a powder bed-laser style 3D metal printer to print tantalum powder, the laser must be sufficiently powerful to rapidly heat a meltpool to that temperature.

Another advantage to using tantalum is that it, like other refractory metals, is highly resistant to deformation. Some metals can begin deformation at relatively low temperatures, particularly aluminum. But the refractory group of metals does not deform until at least 1500C, making them idea for use in very high temperature applications.

Tantalum is particularly resistant to chemical attack, suggesting it’s also best used in medical applications.

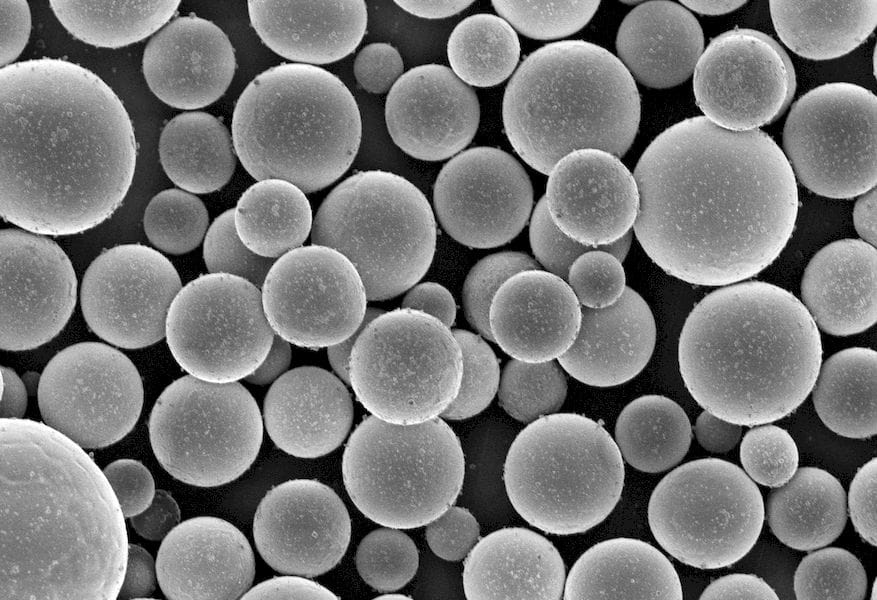

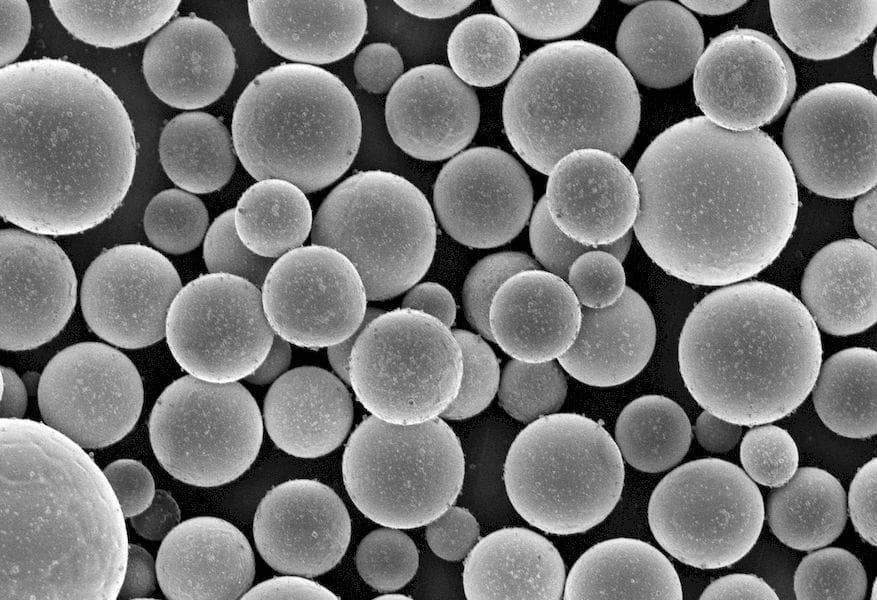

LPW has arranged to produce a tantalum powder specifically for 3D printing (image at top). They’ve partnered with Global Advanced Metals, a world-leading source of tantalum – and niobium, as the two metals are most often found together. GAM sources the metal, and LPW converts it into usable 3D printing powder.

With the availability of tantalum powder comes the next step: what applications will make use of it. I have two thoughts, which parallel uses of other materials.

First, it’s likely those currently producing tantalum products may consider alternative methods of producing those products using 3D printing techniques. That’s a relatively easy analysis. What’s harder is the other approach, where the ability to create objects in any arbitrary geometry could lead to entirely new products made from tantalum.

As usual, the best things are hard.

Via LPW