Josef Prusa provided an update on his company’s progress on building, improving and shipping their new MK3 3D printers, but also announced a big change.

Prusa Printers is one of the world’s biggest suppliers of desktop 3D printers, now shipping well over 3,000 machines per month (actually it’s probably much higher than that now). Their highly transparent, open source approach is almost unique in the industry, but it also provides us with a way to observe their progress like no other company.

While this can show everyone progress, it also shows everyone any problems that are encountered. Marketeers may not like this, but I find that if I see both sides of the equation, I am far more trusting of the company. They seem to be a lot more honest than companies that only tout good news.

What bad news has Prusa told us? In the past we’ve followed their progress on their fascinating multi-material 3D printer.

This is a device that is to 3D print in four different materials. It includes a very fancy mixing nozzle that’s fed by four independent Bowden extruders. Software controlling operations will meter the filament in different combinations to result in color mixing or material substitution, all during printing.

With this device you can actually print in many colors, although its not particularly fast due to the requirement to purge some material when colors are changed.

Prusa has had some challenges with the “MM” version of their MK2 desktop 3D printer, but finally managed to ship it, and their clients do like the machine.

But then Prusa upgraded their main machine to the MK3, with a large number of improvements.

The question that immediately rose was, will there be an “MM” version of the MK3? Apparently yes, but they had to do some work to get it completed. That’s a fair assessment, but then suddenly last week they announced the design would not be going forward. Prusa explains:

I have some bad news you will actually really like.

In short, the new Multi Material upgrade is delayed until the beginning of May. We ported the same Multi Material as we have for MK2, but we were actually developing an alternative system which we like a lot more and I chose to use that one instead. We, however, need a little bit more time for manufacturing some of the parts.

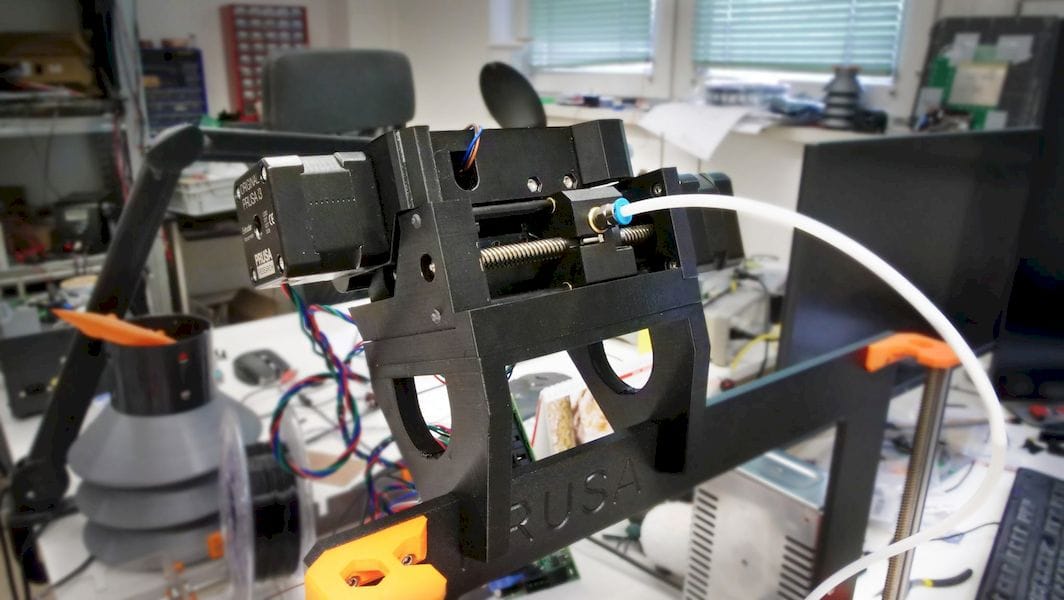

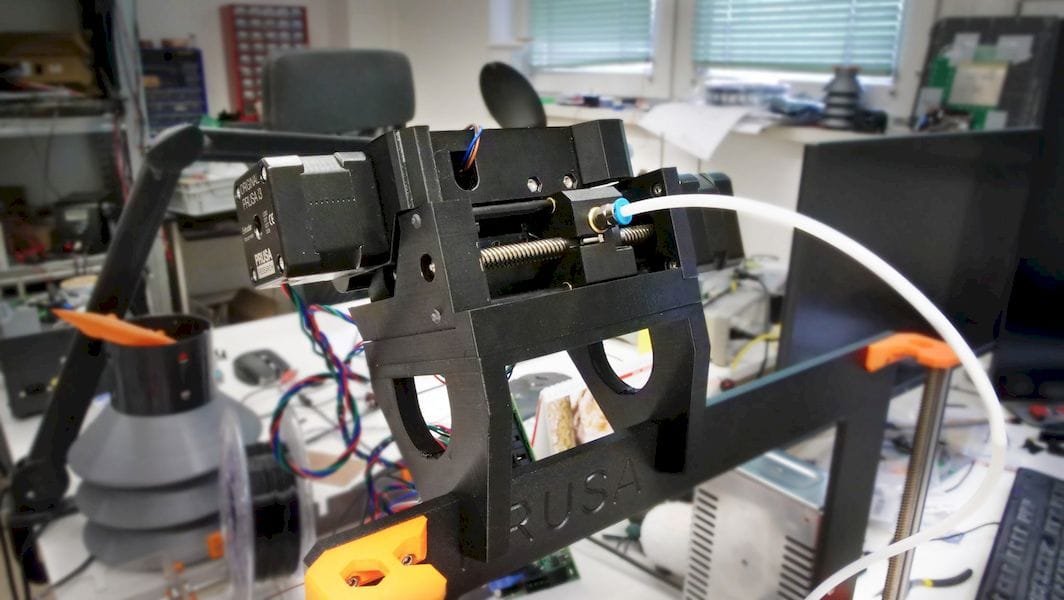

Prusa explains that the new design will in fact be able to 3D print FIVE different materials, so there’s one more spool involved. At top is a pic of the prototype of this design. It seems to have two motors: one for pulling filament, as usual, and a mysterious second one attached to a threaded rod. Perhaps this rod will have different input filament channels on it, and the motor positions them in front of the extruder? We’ll find out in the future.

If there’s no Bowden design here, then the new MM module will likely require only one extruder motor instead of four (or five, I suppose). That should make the price of the new MM system far less expensive, and Prusa verifies this:

It is cheaper. All current orders will get a voucher for the difference or partial refund and existing orders of Multi Material upgrade kit – from MK2 to MK2.5/MK3 will receive version 2.0 even that it will be more expensive.

I think this is a very wise decision. When faced with selling a complex or simple system, the choice is clear. I think by making this decision, Prusa has eliminated a great deal of support calls in the future.

The only catch here is that you’ll have to wait a bit longer to get your MK3-MM Prusa i3 desktop 3D printer.

Via Prusa Printers