A French company has devised a different way to provide 3D print services to manufacturers.

The problem being attacked here is the low-volume production market. This market exists because there are those who require smaller volumes of products than would otherwise justify the expense of setting up a traditional manufacturing line.

Several 3D print companies have attempted to capitalize on this market by using arrays of 3D printers to meet this demand. 3D printers are an ideal mechanism to perform low-volume manufacturing because they are essentially programmable and do not require any complex set up, as a typical mass-manufacturing operation would. You simply send the 3D model through the system and it’s made.

The usual low volume approach is to set up racks and racks of (hopefully) low cost 3D printers and run them in parallel to create quantities of the desired objects. Sometimes there is a twist by automating some of the process with robotic bed replacement, such as is done by Stratasys, Formlabs and 3D Systems.

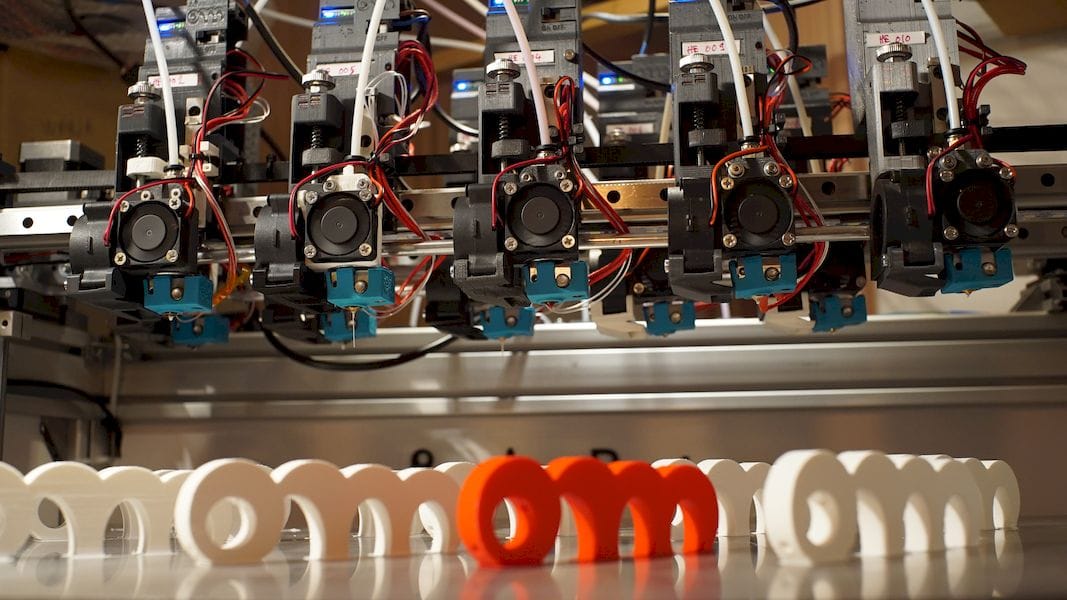

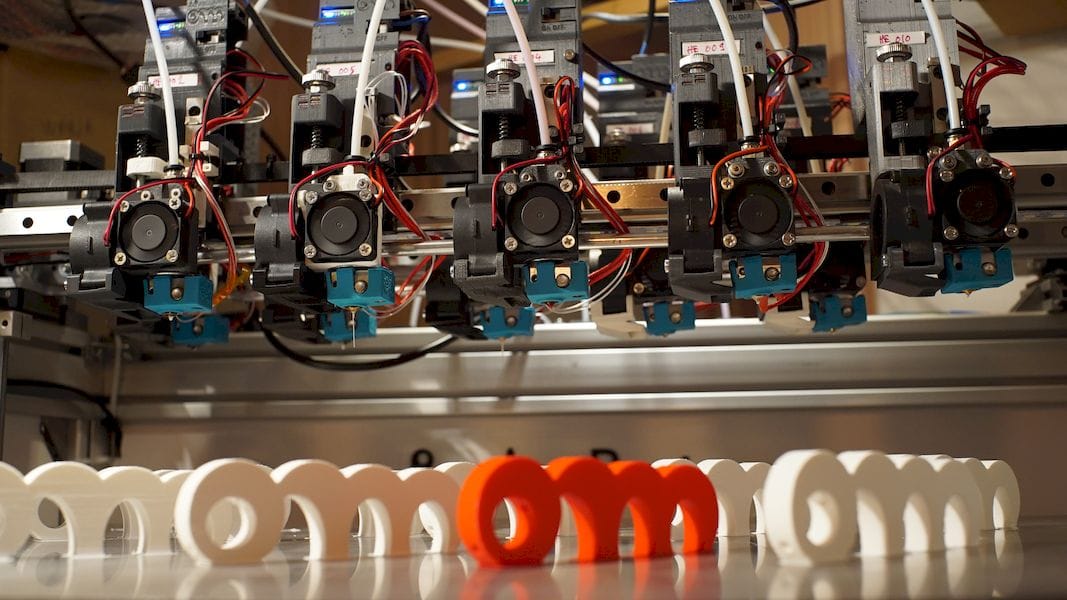

But Bombyx Prod takes a very different approach: instead of adding 3D printers to an array, they add more print heads. And in their case, they can add up to TEN!

This configuration means Bombyx Prod can print up to ten copies of an object simultaneously on a single machine. They are also able to modify the machine to offer fewer print heads, should a part be bigger than would be allowed with ten print heads sharing the build volume.

There are a number of multi-head 3D printers on the market that offer parallel or even independent 3D printing, but none approach Bombyx Prod’s quantity of ten. The closest machine to this could be Stacker’s, but it offers only four print heads.

The Lyon-based company started recently with two engineers who thought there must be a better way to perform low-volume manufacturing using Industry 4.0 techniques. They arrived at a solution that is essentially Industrial IoT. Their design is not limited to only 10 printheads – apparently they can handle as many as 250! But as of this writing, they do not appear to have deployed a machine of that size.

While they have been developing the system for a while, they launched their service in secret last September. Why keep it secret? They wanted to refine their process to delay competition, but at this point they appear to be in the lead for this type of machine.

The system seems quite powerful and extensible, but Bombyx Prod does not intend to sell it; instead they plan on building more as their manufacturing service expands. Building their own machines should make their internal costs lower than competitors who must buy their equipment from other manufacturers. However, it is possible they may integrate their equipment into client’s manufacturing systems.

Currently they have deployed five systems internally, which they say is the equivalent of 35-45 “normal” 3D printers. Their plan is to scale up as soon as they land new clients, and it’s also possible they may offer “dedicated” systems to busy high volume clients.

The parallel nature of the equipment means the slicing operations are relatively straightforward, and they actually use Simplify3D in conjunction with their own in-house software.

For materials, they’ve partnered with Nanovia and OWA 3D for typical PLA, PETG and ABS filaments, as well as use of colorFabb products. However, they say they specialize in use of composite materials, such as carbon fiber filament or flexible TPU.

Currently Bombyx Prod is selling to the EU, but it is entirely possible they may soon offer their services to many other parts of the world.

Via Bombyx Prod