An inexpensive new making machine has emerged, one that performs both additive and subtractive manufacturing.

The 5AXISMAKER is a desktop fabrication machine that, like some other units, employs multiple making technologies all in one box. This one combines CNC milling and 3D printing in a single platform.

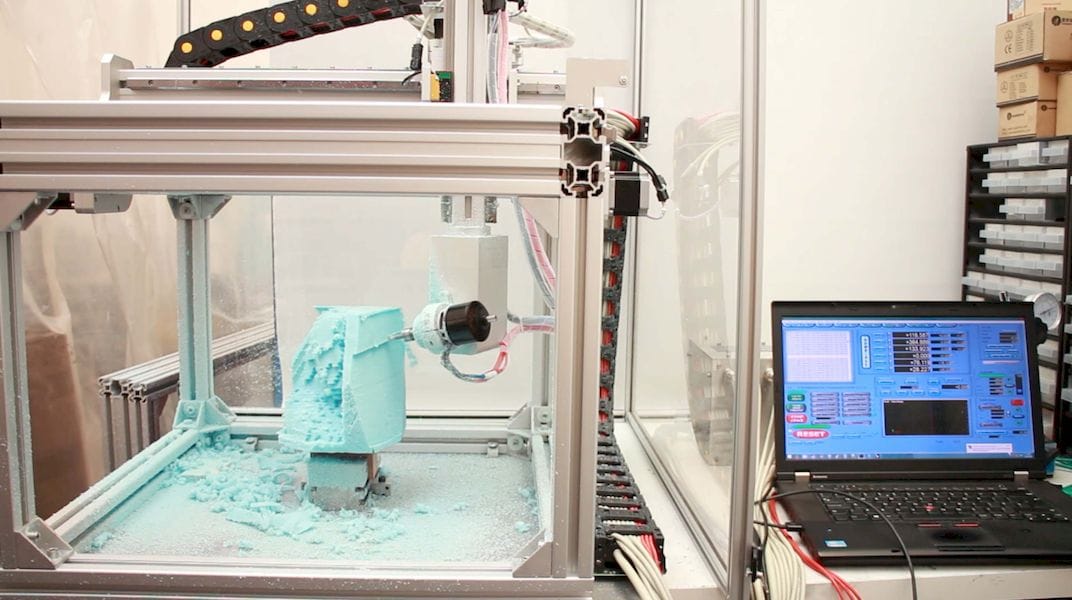

Unlike many of the similar multi-tool devices we’ve examined in the past that have been essentially desktop 3D printers converted into CNC mills by adding a toolhead, this machine appears to be a CNC mill that has added a 3D print toolhead.

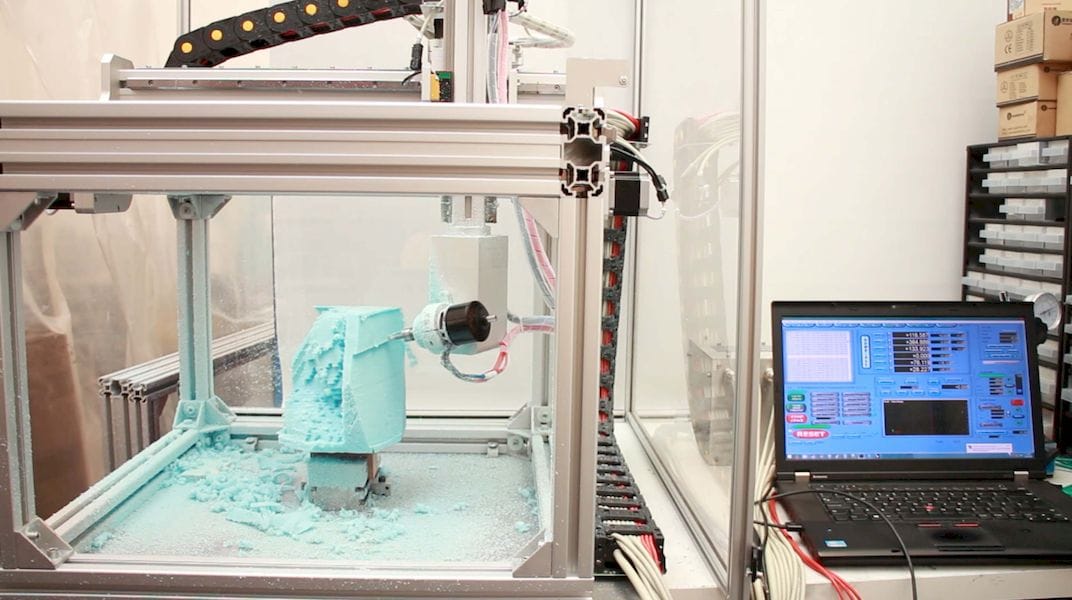

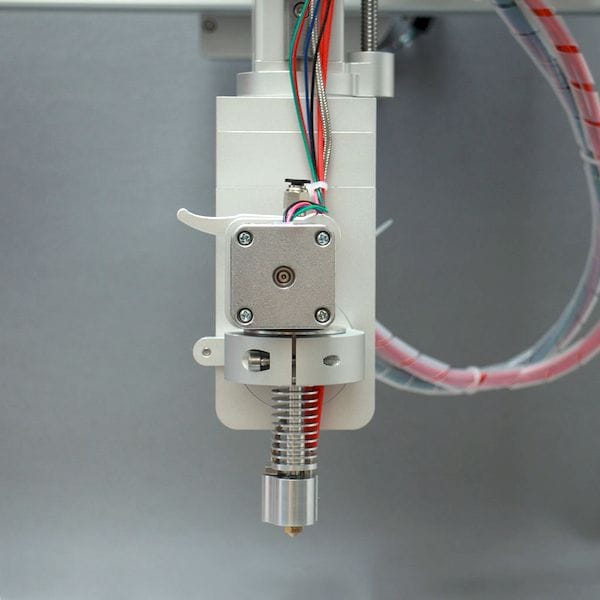

The 3D print toolhead comes equipped with a rather coarse 0.6mm nozzle, but the company says you can also obtain a more standard 0.4mm nozzle – and an enormous 1.2mm nozzle if you so choose.

For now this machine can 3D print only PLA because it does not include a heated print surface. I suspect this is because the complications of including that as well as a CNC-capable platform were a bit too much. You don’t want your CNC mill to be carving your electronically heated print bed, do you?

I point this out because I believe this to be a very important factor. Many of the other machines I’ve looked at have been quite competent at 3D printing, but are woefully weak when it comes to CNC milling, as that process requires a lot more power than simply pushing a 3D print toolhead against air. A CNC mill must push the milling bit strongly against solid material, and that takes robust mechanicals and strong motors.

It seems that it might be easier to convert a CNC mill into a 3D printer than the other way around.

Thus I expect the 5AXISMAKER to be both very competent at both processes.

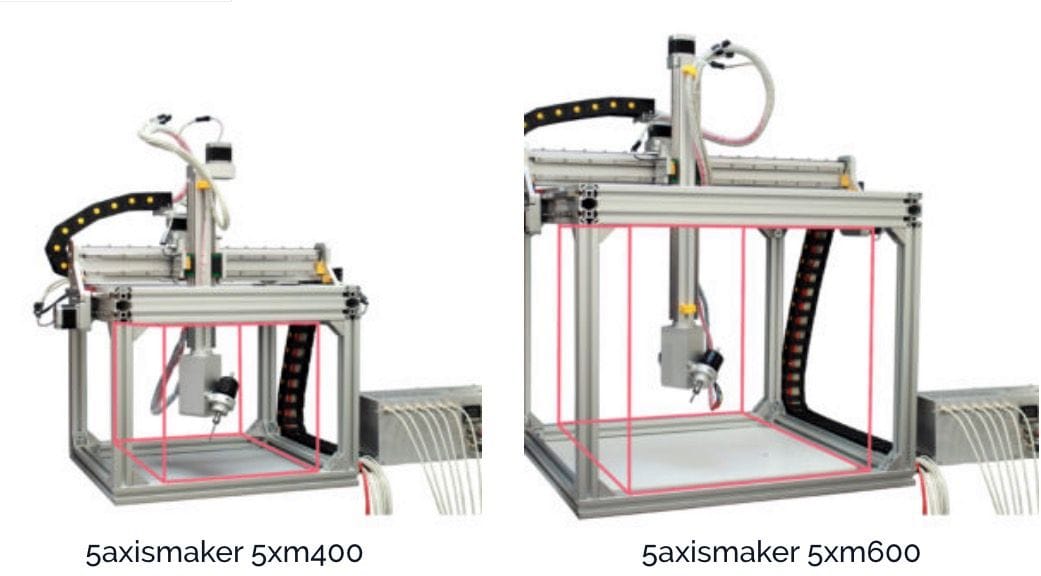

Even better, the 5AXISMAKER happens to include FIVE axes of CNC motion, rather than just the three axes you typically find in a desktop 3D printer frame. This means the CNC mode is able to cut far more complex objects, but it also has some 3D printing implications.

Virtually all 3D printers use a three axis approach to produce consecutive layers to build 3D objects, but when you happen to have a 5-axis mechanism handy, things can change a lot.

Watch this video to see the potential of 5-axis 3D printing:

This approach has been attempted by a handful of 3D printer companies, sometimes with repurposed robotic arms. But regardless of how you do it, it can result in amazingly strong prints because you can change the orientation to match the strength paths required.

The other major advantage of 5-axis 3D printing is the virtual elimination of support material. Why? Because you can simply rotate the print around to an orientation that does not require support anytime you want during the print operation.

Of course, you’ll need some fancy 3D print slicing software to do that.

This is the curse of these multi-tool machines: the software is more complex – and rare – than software for any specific single function. 5AXISWORKS’s standard workflow, after 3D design in CAD, requires a CAM system (such as that included in Autodesk Fusion 360), and then an instance of MACH3, a CNC controller system to run the machine, which cannot be run on its own.

But the real attraction of this system is the price. There are two models of 5AXISMAKER, the 5xm400 (400 x 400 x 400mm build volume) and the 5xm600 (600 x 600 x 600mm build volume) priced at £5,000 (USD$6,200) and £6,500 (USD$8,000) respectively.

That’s not a lot of money to pay for a 5-axis 3D printer when compared to the scant few alternatives available today.

Via 5AXISWORKS (Hat tip to John)