Yesterday Madrid-based Microlay announced a very powerful desktop 3D printer for the dental industry: The Versus.

I have to admit there are now dozens of 3D printers for the dental industry, each with different qualities and capabilities – and pricing. With the recent lapse of patents, there has been a flood of resin-powered 3D printers of all kinds, many with extremely low pricing.

With all this choice, it’s become extremely difficult for companies to distinguish themselves in the market. Some companies have chosen to do so via marketing approaches, while others follow a more technical path.

One of those seems to be Microlay. The Spanish company has produced resin 3D printers for a few years, but now has come out with a machine that they describe as “our most ambitious 3D printer”. I tend to agree with that, after reading the specifications and features of this machine.

It is relatively easy to throw together a laser, resin tank and motion system and say you have a 3D printer, but how do you make it “better”? It seems that Microlay’s experience with this technology has led them to develop the Versus, which seems to have features I haven’t seen in many other machines.

Let’s take a look at what caught my eye.

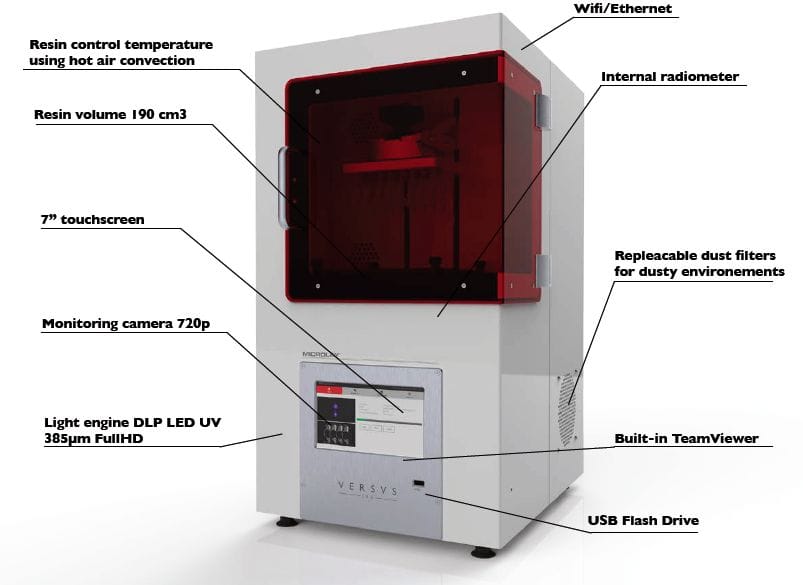

They seem to pay particular attention to temperature, which is a critical factor in achieving the highest quality prints. In open-frame machines, this is not even a consideration, but in the closed-environment Versus they employ active heating – of the air in the chamber as well as the resin. This creates what they call a perfect “microclimate” for the solidification of resin. The air is at the right temperature and the resin is at the optimum viscosity.

Temperature control is also extremely important if you hope to continually produce consistent results; ambient room temperatures can vary by season and time of day.

Another interesting difference is that they use (optionally) a 385nm light instead of the defacto standard 405nm wavelength. They say this enables them to print with “incredible precision”. I’m not sure that the slightly smaller wavelength size does this, as the difference is literally microscopic, but it may have more to do with the transparency of resins to this particular wavelength. And it’s provided by a solid-state unit for extreme reliability and lifetime.

Another very intriguing feature is that they optimize the light delivery to all points on the resin surface. With lasers, for example, the beam must tilt slightly as it attempts to reach the corners. This tilt makes the impact point oblique and thus slightly less power per unit area. Thus you get inconsistent power application throughout the print. Apparently Microlay has figured out a method for avoiding this effect, likely using custom lenses and software power management. They say:

The quality of the projector components and software of the Microlay Versus ensures that all points of the printing tray receive exactly the same energy dose.

Another very interesting feature that is not explained is that they say you do not need to replace the resin tank, something that must happen on virtually all other 3D resin printers. This could significantly reduce the cost of operation.

That operational cost is further reduced as this machine does accept third party resins; this is an open materials machine! I would not have expected this, as machines of this caliber typically have closed resin ecosystems to extract maximum profit from users, as well as ensure quality print results.

Microlay says the Versus can print at up to 50mm per hour vertically, which is definitely quick.

Size-wise, this is not a large volume 3D printer, with a chamber size of only 125 x 70 x 180mm. This is usually not an issue with the target dental market, who always print small items.

The resolution levels on this machine are impressive, with the X-Y able to achieve 0.065mm and the Z axis able to move at a very tiny 0.001mm per layer. That’s pretty small!

The machine also includes the usual convenience features, like WiFi, LAN, on board monitoring camera, etc. A dust filter enables high-quality use in less-than-perfect workshop environments. One interesting feature is that they’ve integrated the TeamViewer software directly into the machine, so you can very easily connect and control it from anywhere on the Internet.

The Microlay Versus Dental 3D Printer is clearly addressing the technical needs of their market. If you are seeking a dental 3D printer, this is one you should consider.

Via Microlay