A Kickstarter project proposes an inexpensive water cooled head for 3D printers.

Wait, why would you need this? Let me explain.

There is a bit of a paradox in filament-based 3D printers: you have to heat the filament up to just the right temperature to perform the extrusion and bond to other layers of the print, yet at the same time you must maintain a normal temperature for other portions of the filament to ensure printing continues.

In other words, the hot end of your 3D printer is demarcated into two zones: a hot zone, where the filament softens for extrusion through the nozzle, and the cold zone where the filament maintains its strength and its rigidity is leveraged to push the filament into the hot zone by the extruder motor.

In most filament 3D printers there are two heating control mechanisms to accomplish this: a resistive heating element to precisely warm up the hot zone, and cooling fins with a fan to ensure the heat doesn’t get into the cold zone.

If the heat does make its way into the hot zone for some reason, an effect known as “heat creep”, you are in danger of a failure. Should the heat be sufficient to soften the filament even slightly, then it might no longer be properly pushable, and you get a jam. If more heat arrives, then the filament could melt and flood the cold zone, creating a rather tricky problem.

Because the cold zone is not designed to be heated up to this level, it’s very difficult to clear out the wayward filament.

Thus it is important to keep the cold zone hot, even though the hot zone may be quite a bit warmer. That’s why those fans are running.

Until recently this hasn’t been that big a problem. However, a couple of relatively recent developments are aggravating this cooling scenario:

- More exotic materials are becoming available in filament form suitable for 3D printing. Some of them are printed at much higher temperatures, raising the possibility of heat creep.

- The desire to 3D print faster sometimes requires higher extrusion temperatures to soften the filament more quickly as it rapidly moves through the hot end. These higher temperatures also may result in heat creep.

- To better control print quality, enclosed build chambers attempt to capture heat, sometimes up to 70C. This reduces the effectiveness of fan systems, because they’re just blowing hot air at the cooling fins.

Water-Cooled 3D Printer HOT-END

Brian Eaglestone is raising funds for Water-Cooled 3D Printer HOT-END on Kickstarter! Make a lightweight water-cooled 3D printing hot-end a commercial reality, fully prototyped and ready for production.

<blockquote class=”embedly-card”><h4><a href=”https://www.kickstarter.com/projects/1789827891/water-cooled-3d-printer-hot-end/description#prototype-slide-117144″>Water-Cooled 3D Printer HOT-END</a></h4><p>Brian Eaglestone is raising funds for Water-Cooled 3D Printer HOT-END on Kickstarter! Make a lightweight water-cooled 3D printing hot-end a commercial reality, fully prototyped and ready for production.</p></blockquote>

<script async src=”//cdn.embedly.com/widgets/platform.js” charset=”UTF-8″></script>

Of course, there are desktop 3D printers specifically designed to handle higher temperatures, but there are many machines that are not. For them, these goals may be out of reach.

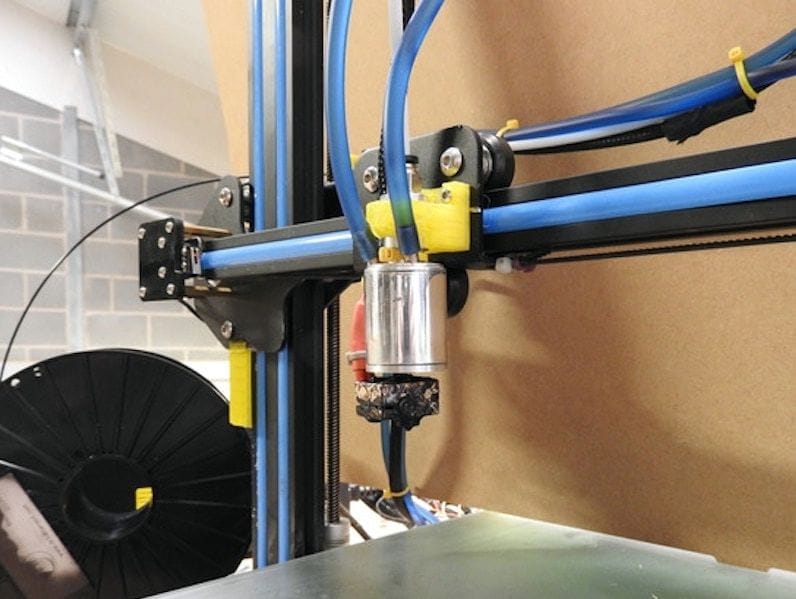

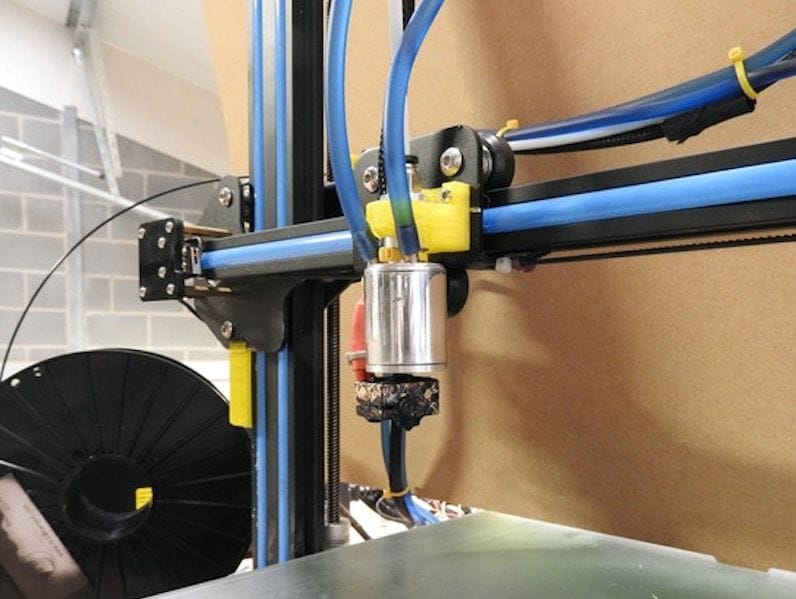

That is, unless they consider a modification like the one being developed by UK’s Brian Eaglestone, who has devised a relatively inexpensive water cooling system that can apparently be used with E3D hot end systems.

Instead of a fan blasting ambient air there is a water jacket surrounding the cold zone. This is continually refreshed with cool water externally with a pump and tube system.

According to Eaglestone, the water stays at around room temperature, even if being used in a closed build chamber at temperature.

This modification should enable some desktop 3D printers to tackle much more interesting materials and even print at higher speeds.

Priced at £175 (USD$250), the water cooled hot end could be an interesting add-on to some 3D printers.

Via Kickstarter