We’re watching a video proposal from RichRap on how 3D printer filament should be spooled.

RichRap, also known as Richard Horne, is an engineer based in the UK who is well known for his ongoing exploratory 3D printing ventures. We’ve learned much from watching his always interesting videos, and you should too.

This past week Rich offered a proposal to simplify the world of 3D printer filament spools that he calls the “MasterSpool”.

The idea is to combat the usual perils of using common 3D printer spools obtained from distributors. These typically very strong plastic spools tend to have a number of issues:

- They’re heavy and add to shipping costs, which are already usually outrageous unless your supplier is nearby. Rich has measured some at up to 1/3 of the weight of the material!

- They are usually not recyclable and tend to collect, especially if you are a frequent printer

- To recycle them you must transport them somewhere, using up more resources and more importantly, your time

- They’re often different sizes between vendors, making it challenging to set up universal mounting systems for printers using open filament

Rich’s proposal is to instead make the spool part of your 3D printing infrastructure and not part of the packaging from filament vendors. Basically you keep re-using a standard “MasterSpool” that’s designed to easily accommodate raw, unspooled filament shipped from a vendor. It’s like getting a “refill” for your spool.

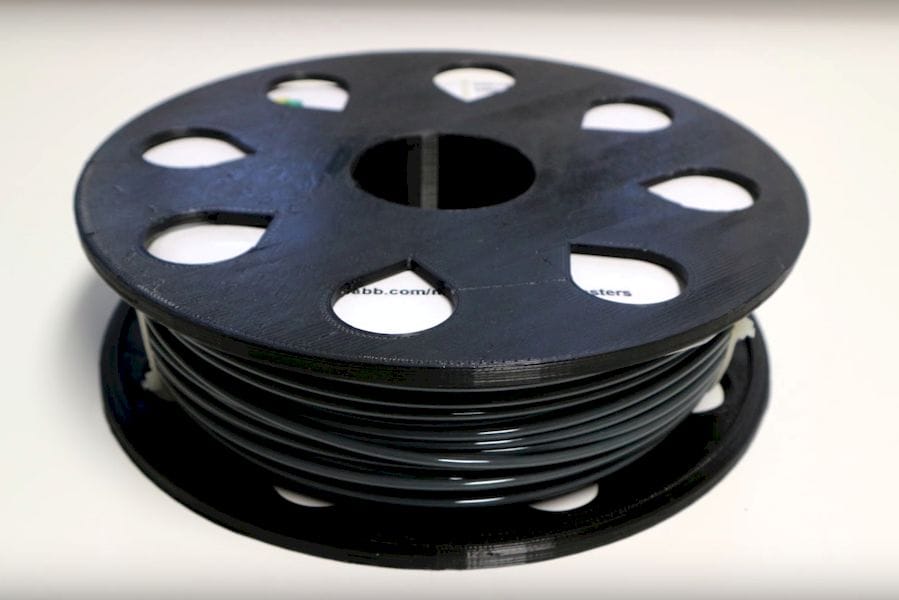

The MasterSpool itself is two easy 3D prints that form the two sides of the spool. Rich has designed them to easily screw together, making mounting a fresh pile of filament mostly trouble free.

There are some advantages to both the user and vendor using the MasterSpool:

- Less costly shipping

- No need to keep buying, shipping, and recycling spools

- No need for a vendor to be concerned about the spool size; the user handles that with the MasterSpool instead

But for this concept to take hold, it would require filament vendors to switch over, or at least offer, filament bundles without spools. Rich proposes a simple tie-wrapped coil with a single sheet of branding cardboard, all enclosed in a plastic bag.

The question is whether the filament vendors would do this. They may have some objections, which could include:

- Doubling their product SKUs, because they likely can’t stop selling spooled filament to non-MasterSpool buyers and buyers requiring spools of specific sizes for particular machines

- Desire to provide more significant packaging to better protect the “naked” coil of filament

- Need for bigger 2D space on the package for branding material

- Need for standard, fixed-shape packaging for use in retail sales

So it’s not clear whether this will catch on. The filament vendors will need to somehow make some new money on the concept in order to motivate them to introduce it. Perhaps one will do so, with a view to attract lower-cost volume buyers. If they succeed, then others may follow.

In the meantime, the MasterSpool is obviously highly useful for anyone buying filament coils from those who do sell them.