Dyze Design has been producing interesting 3D printer components for years, but now they’re about to unleash something very powerful.

The company has developed an extrusion nozzle that is mostly made from Tungsten Carbide, a rather unusual material that seems ideal for use as a 3D printing nozzle.

The company was spurred towards developing this product due to ongoing issues with current nozzle solutions.

The nozzle of an extrusion-based 3D printer is one of its most important components, as that is the point where the thermoplastic leaves the machine and becomes the 3D print. It must perform consistently in a number of dimensions:

It must efficiently transfer heat from the heater block, which, as you can imagine, is not actually at the business end of the nozzle; it’s located a short distance away, and its heat must flow through the metal of the nozzle to the tip.

It must resist wear from unusual materials. Some metals commonly used for 3D printer nozzles are made from materials that are actually softer than the materials going through them. For example, carbon-fiber infused filament will gradually erode the soft nozzle and change the diameter of the nozzle’s opening.

It must maintain shape when heated; some materials tend to expand when heated, distorting the size of the nozzle and confusing the extrusion sequence.

It must provide a smooth and frictionless surface for the thermoplastic to flow through. You don’t want the filament to stick to the sides of the nozzle during extrusion. This is particularly important for flexible materials, which tend to stick.

The problem in designing an effective 3D printer nozzle is trying to balance all of these factors. Quite often you may hit some, but completely miss on others. Steel nozzles, for example, are very hard, resist erosion and don’t distort under heat, but have crappy thermal flow.

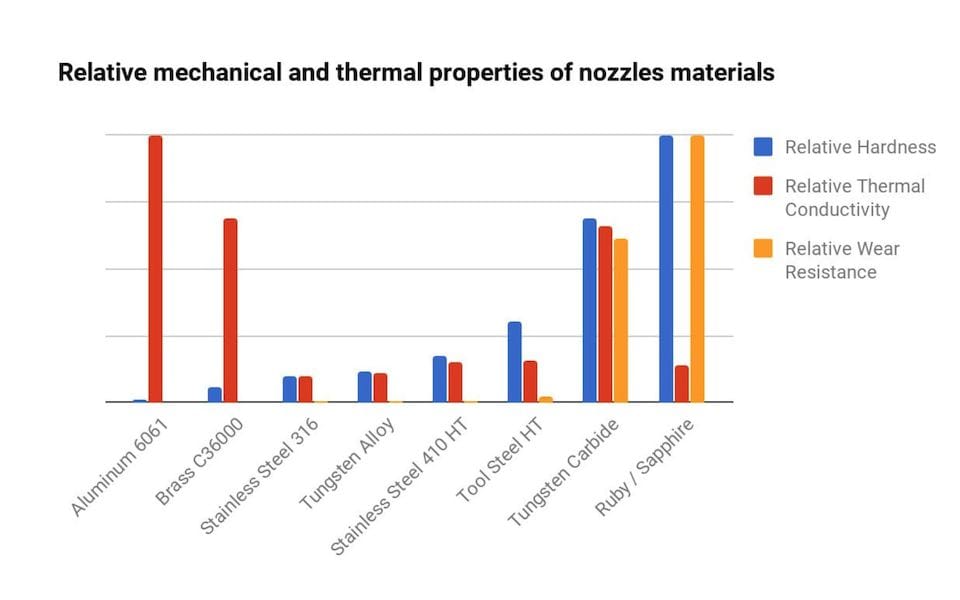

Montreal-based Dyze Design has provided this chart to illustrate the dilemma facing different materials:

Notice, however, that tungsten carbide offers a reasonable compromise with all of these factors. Tungsten carbide is actually a ceramic material, not a metal, like you would find with a tungsten alloy nozzle. Thus it is much harder.

Well, there’s one more point: Dyze Design’s nozzle design involves coating the internal flow path with nickel, which provides for a sufficiently slippery surface that should, when combined with tungsten carbide’s properties, allow for a very functional nozzle.

These performance characteristics should provide for some very attractive 3D printing benefits:

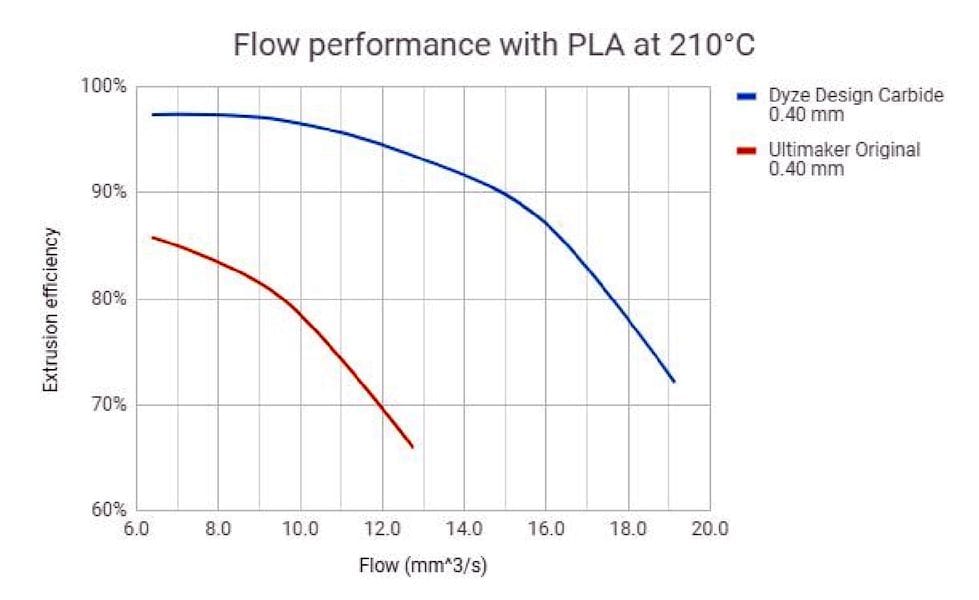

- Printing can be faster, because heat flows more easily to the nozzle to warm up passing material

- Print quality should increase as the heat and nozzle dimensions should remain more consistent throughout the print

- The nozzle will more than likely never wear out, regardless of what you push through it

Dyze Design says that they new tungsten carbide nozzle could be the only nozzle you’ll ever need, as it should handle virtually all known 3D printing materials, and I don’t doubt it.

Can you get one of these nozzles? Not exactly yet, because they intend on launching the product on Kickstarter in the near future – March 5th, to be precise. We’re told the launch price will be only USD$50 for one of these unusual nozzles. For now, however, you can sign up for their mailing list to get advance notice.

Via Dyze Design