There seems to be a pattern emerging in the world of manufacturing services, at least from a 3D printing point of view.

There are a number of dedicated 3D print services in existence today, some have been around for many years, while others have just started recently. The idea is that you could employ the equipment and expertise of a professional 3D printer operator, rather than trying to figure it out yourself, or spend the effort and funds hiring people and buying equipment to do so.

In many cases this is a wise choice for business and individuals, as the cost and effort required to get up to speed in this world can be considerable. The answer was simply to outsource the work to a 3D print service.

And that’s the way the world worked, at least for a while.

But in the past year or two, I’ve noticed something interesting happening. Many of the previously dedicated 3D print services have added more functional to their offerings – beyond just 3D printing. It might include milling, injection molding or other traditional manufacturing techniques, but the point is that it isn’t 3D printing, and it is making.

Some examples:

- Sculpteo added laser cutting and engraving

- Xometry recently added injection molding

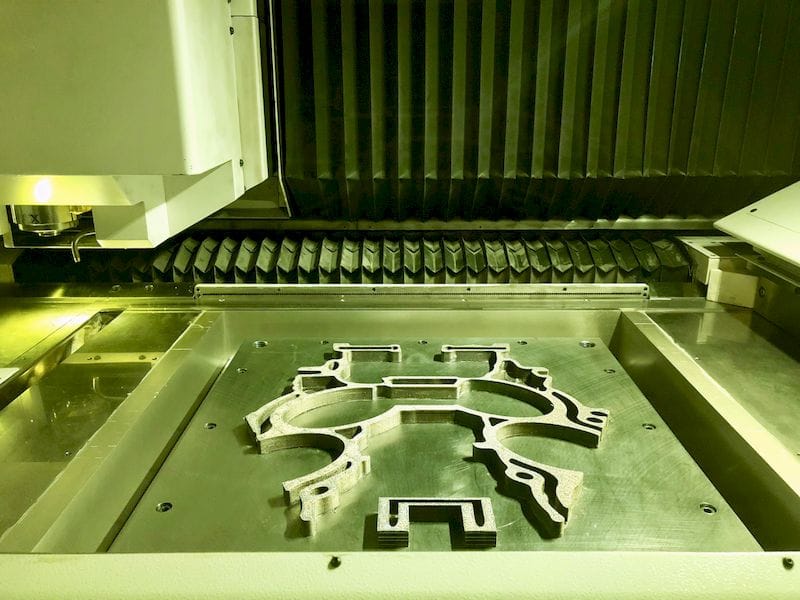

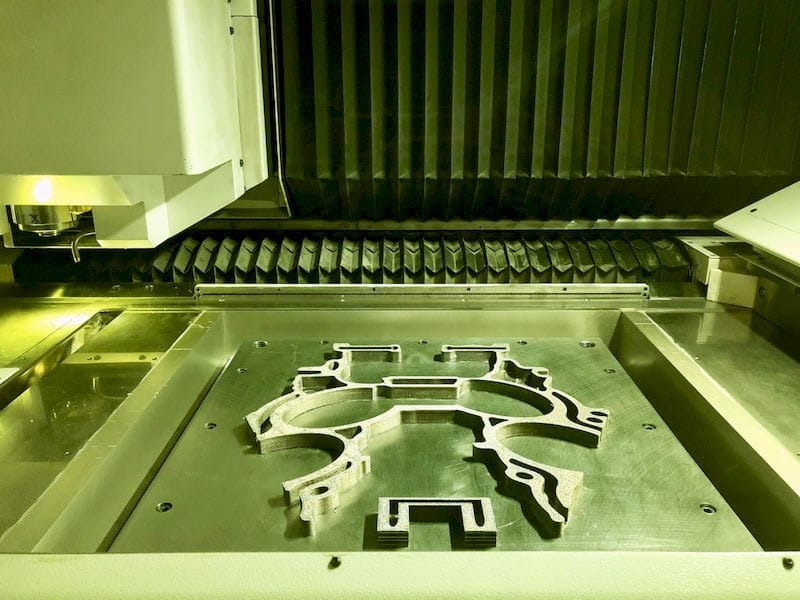

- 3D Hubs added injection molding and CNC milling

And I’m sure there are more examples (although curiously NOT Shapeways, for some reason).

What’s going on here?

I think it is simply this: those who need something made just want it made. They are less interested in the process of making it, so long as they receive the desired object. It’s an increased focus on results and less on the method of achieving it.

It may be that the affected 3D print services were handling enquiries from clients in this position, where they wanted other making processes – not because they were interested in the process, but because the other processes were vastly less expensive in many scenarios.

And these services got tired of turning them down.

3D Hubs even went as far as to officially change their corporate policy and goals towards a more general manufacturing orientation recently.

There are a large number of contract manufacturing services that have not previously employed 3D printing, but now they’ve added it. One example is Protolabs, who started in 1999 by doing injection molding. Slowly over time they’ve added additional manufacturing capabilities, and added 3D printing a few years ago when they acquired Fineline. They, too, follow customer demand.

So where does this leave us? To me, it seems that the days of a pure-3D print service may be ending, although I suspect Shapeways may have a thing or two to say about that.

The word of the day is “convergence”, where non-3D print services add 3D printing, and 3D print services add non-3D print services. They’re all inevitably heading in the same direction: universal manufacturing with the best and most appropriate tools.

This switch also good news in a way: an item “3D printed” no longer a magical thing on it’s own. Results are what counts.

There is no thrill in 3D printing anymore.