We encountered a lengthy video that details the challenges of 3D metal printing.

The video, produced by America Makes, includes a lengthy discussion of 3D metal printing by Dr. Hao Peng of 3D Atlas, where he takes the role of Vice President of Product Development.

This makes much sense, as his company produces the Sunata System, which we covered last week. This product attempts to automatically determine the best way – for your application – to print a given part on a 3D metal printer, at least if its of the DLMS variety.

The problem is immensely complicated, and having an automated tool to handle the problem is certainly welcome. While I knew the problem was complex, I had no idea the degree of complications.

In the video, Dr. Peng goes over a wide variety of situations and explains in great detail the challenges of 3D metal printing in a way that will most certainly open your eyes to the problems evident in this technology.

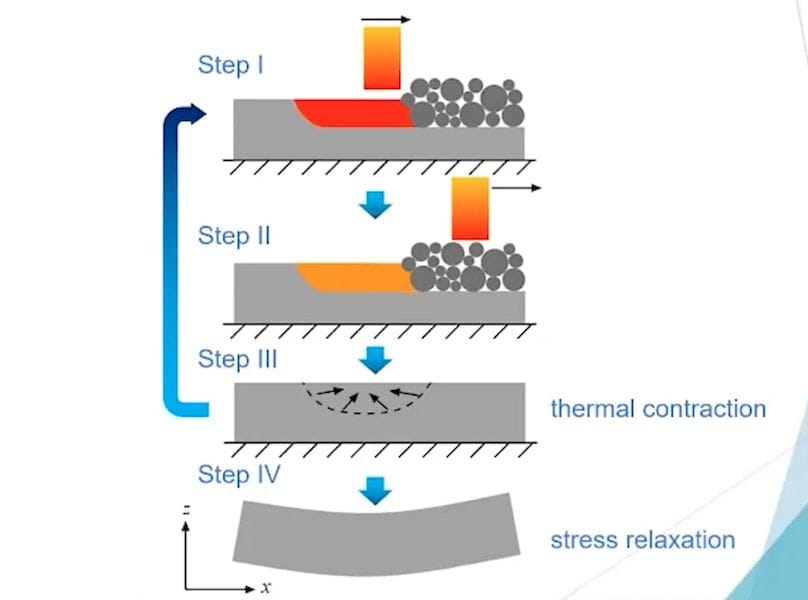

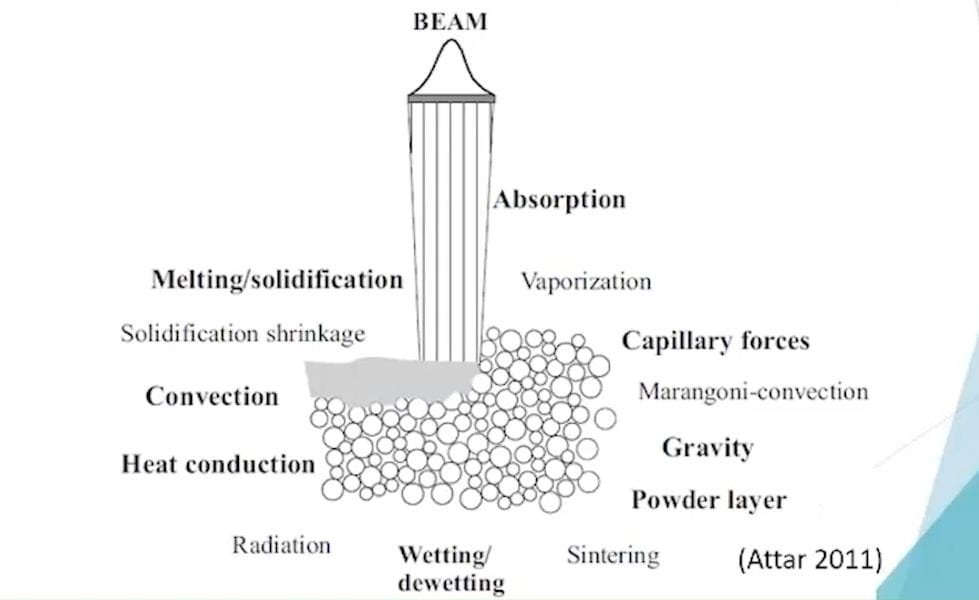

The major idea is to determine the sources of thermal distortion and attempt to mitigate them with multiple strategies. Issues such as cracks, delimitation, support disconnects and distortion are described.

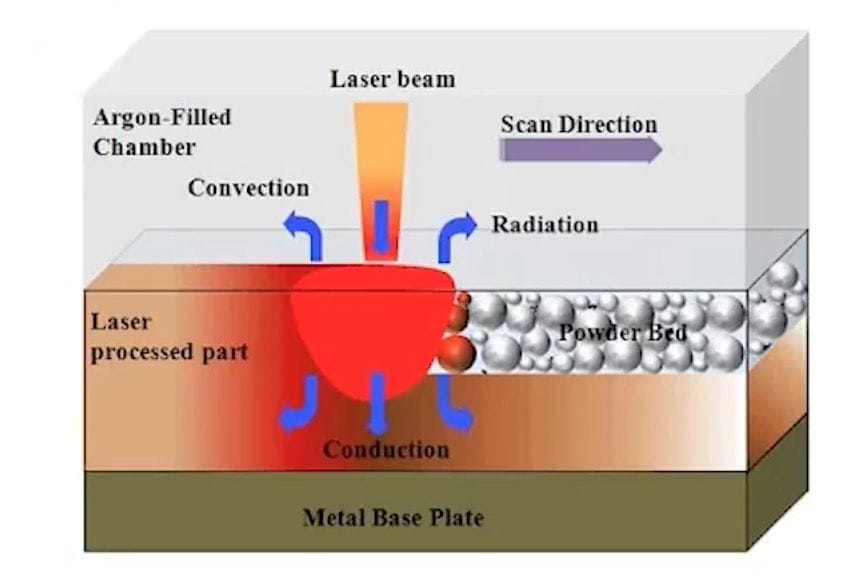

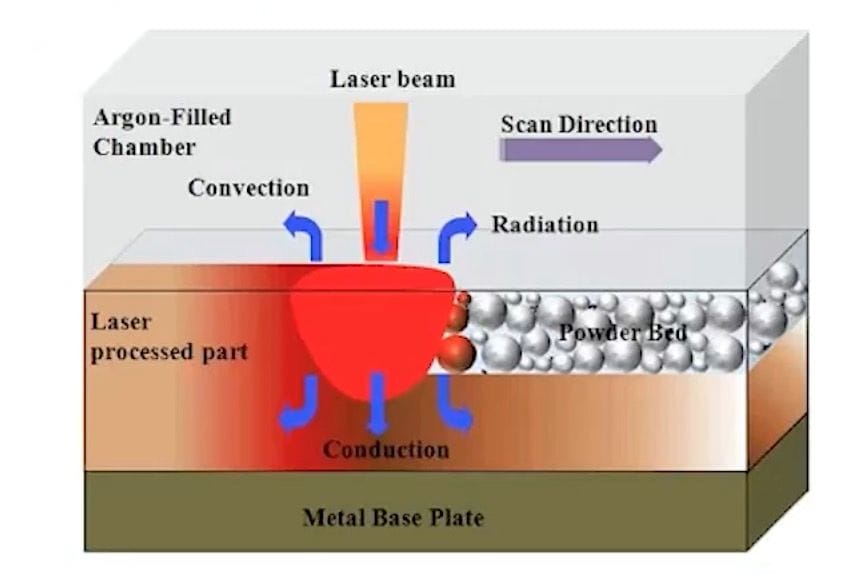

Dr. Peng describes the process of 3D printing from a physics point of view, and analyzes the multiple physical sources of distortion.

The 38 minute video is perhaps the most detailed description of 3D metal printing challenges I’ve seen. And this deals only with the printing aspects; there are plenty of other challenges with 3D metal printing, before and after the actual printing operations occur.

If you’re contemplating getting into 3D metal printing, or have begun doing so, then you may want to watch this video very carefully.

Via YouTube