I don’t know if you noticed, but some styles of 3D metal printers have a problem; a size problem.

While 3D metal printers have been around for years, recent trends have customers demanding the ability to 3D print larger and larger parts. This is particularly true in the prime industries using 3D metal printing, aerospace and automotive, where larger parts are the norm.

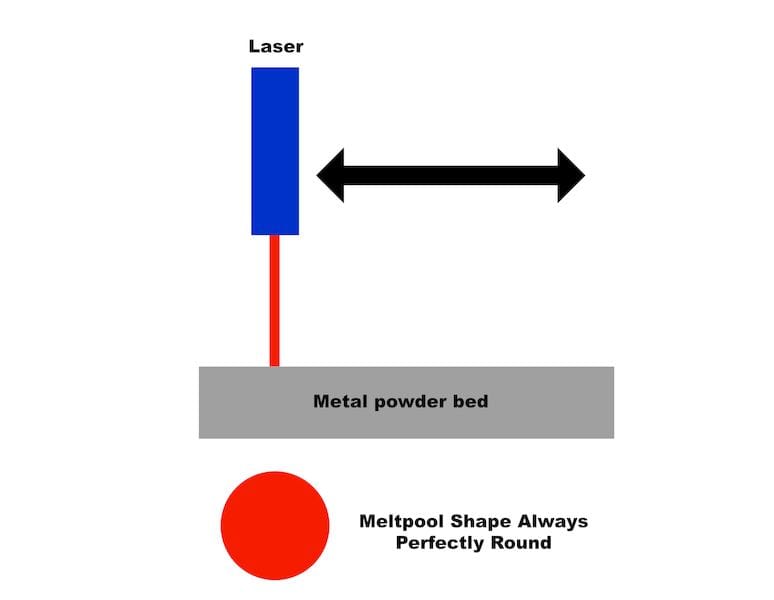

The 3D metal printing process employed by the leading printer manufacturers is the powder-bed/laser approach, in which a powerful laser is blasted at a flat surface of fine metal particles. The laser’s energy creates a “meltpool” that fuses together any particles within the laser’s reach.

By moving the meltpool around the powder bed surface, the 3D metal printer can solidify an entire layer of the metal part. Then by recoating the bed with another layer of powder, the process can repeat, gradually building up the object layer by layer.

This is a proven process that works very well.

But there is an issue to be overcome. Let me explain with some diagrams.

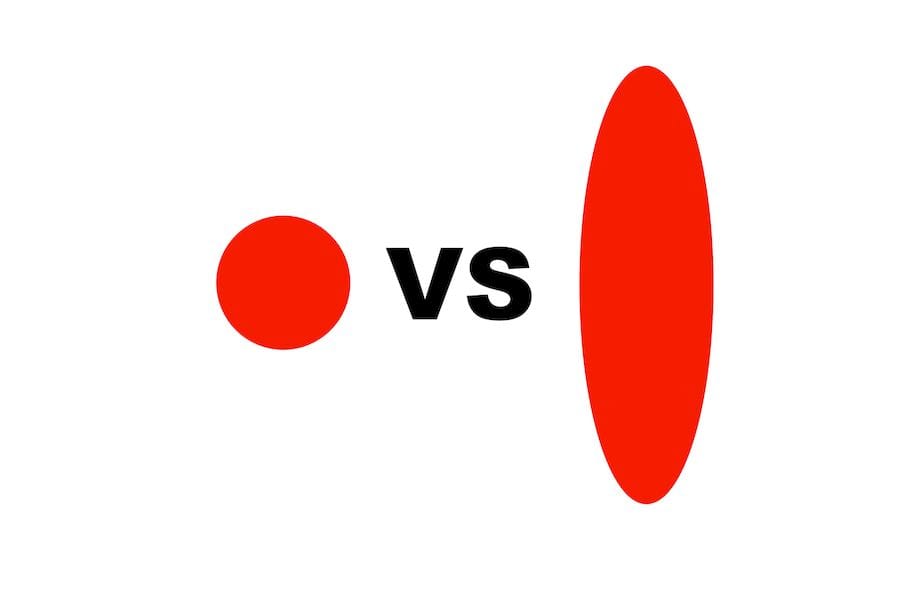

It is all dependent on the method of delivering laser energy to the powder bed. Most machines use a galvanometric approach: a tiny mirror is rapidly repositioned (tilted) by a precision galvanometer. The laser in these systems is in a fixed position, and the mirror deflects the laser power toward different areas of the powder bed as it tilts back and forth.

The advantages of this system are several. First, the weighty laser system itself doesn’t have to be moved around. Secondly, the galvanometric mirror can direct the laser very quickly around the powder, perhaps faster than the laser could move itself, if it were mounted on a motion system.

There are some disadvantages, the most notable being the energy lost through the mirror and the slight loss of focus as the mirror moves.

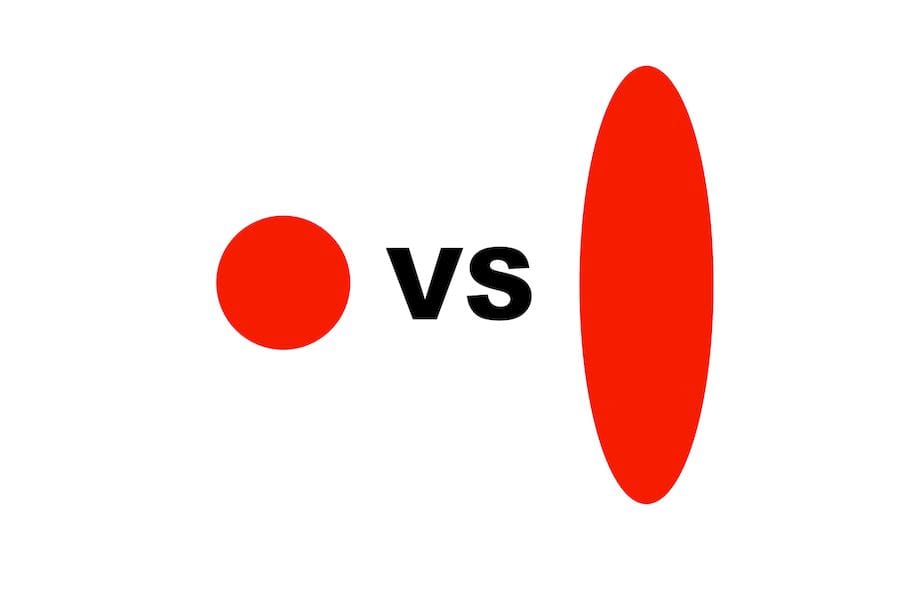

But there is another very key disadvantage that has become apparent as the build volume of these machines have increased. In this diagram we see what happens to the laser meltpool as the powder bed size increases:

The area of the meltpool distorts and enlarges. This causes a couple of issues. First, the energy is applied to a larger area, making less energy per unit area. To maintain melt speed, you must compensate by increasing the power of the laser when this occurs.

Secondly, the shape of the meltpool is different from the other portions of the build surface. This means that the resolution achieved could be less on the peripheries of the build area, and perhaps even compromise the design if fine details were required in those zones.

How can one rectify this issue? Simple: make the device taller!

The height decreases the angle required by the mirror for deflection, and thus reduces the elliptically of the meltpool somewhat. But it does not do so completely.

Larger 3D metal printers now tend to employ multiple lasers in separate zones, which is another way to mitigate this issue. It also can make the printing take place faster, as more lasers are working on the problem simultaneously.

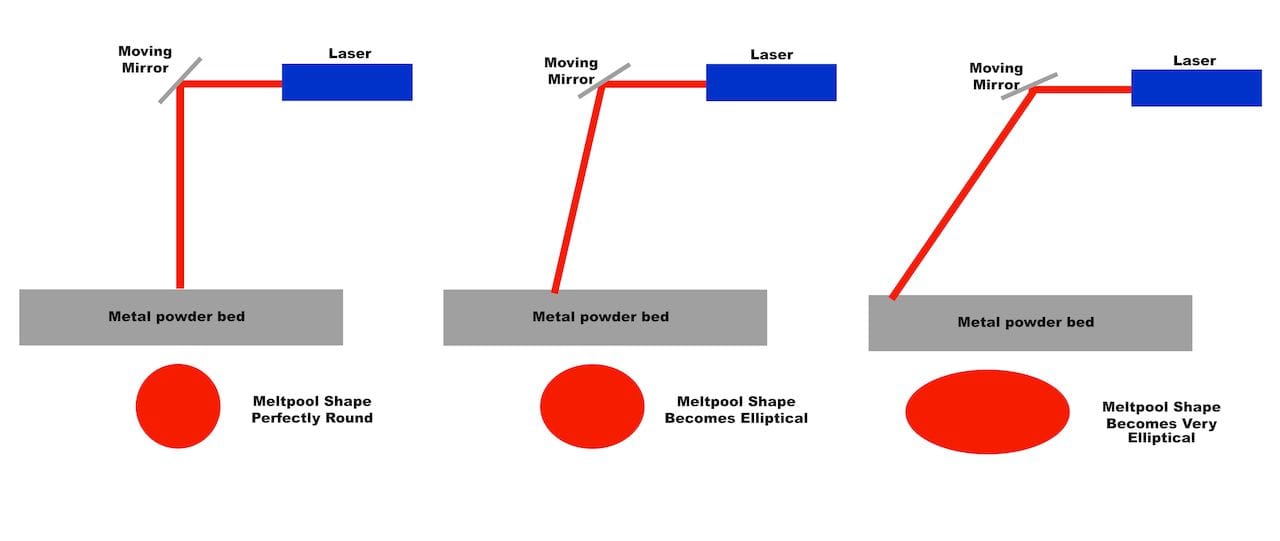

Another approach is to transmit the laser energy directly towards the print surface, as shown here.

This will guarantee that the meltpool will be a consistent, fine point. It also eliminates any distortion generated by the mirror in general and should lead to a higher quality print. However, you still have to move the laser around, which can be difficult, as mentioned.

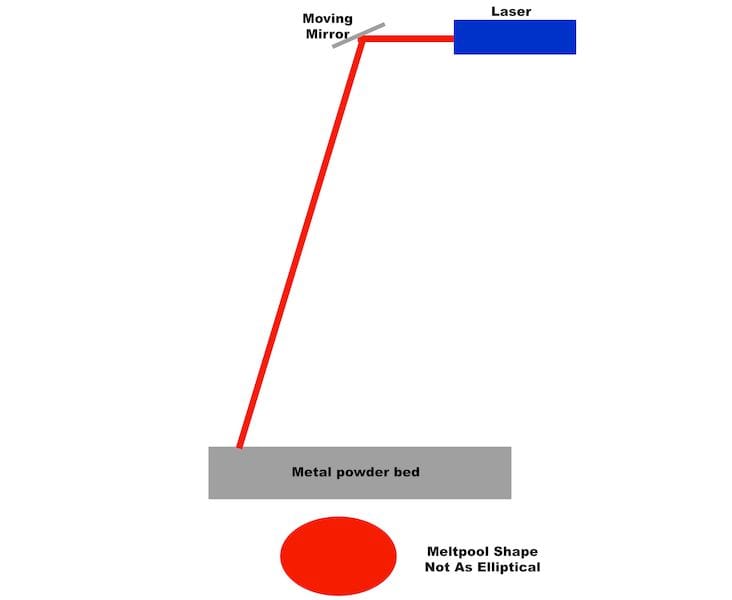

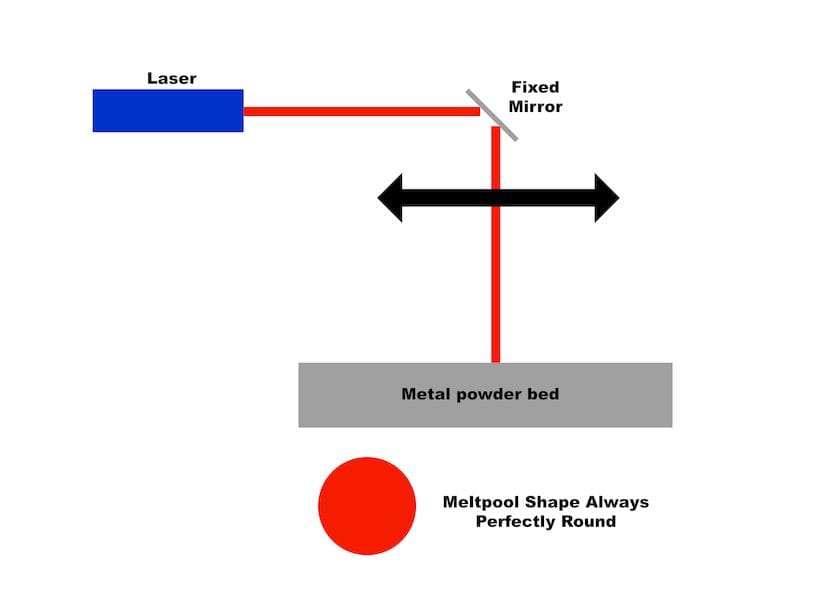

Yet another approach is to use a mirror in a perfectly vertical system, as shown here.

The mirrors are always in a fixed position, and simply reflect the light straight downwards regardless of the position of the final mirror. This approach is used in many laser engravers, and could be used for 3D metal printing as well.

What does all this mean? As always, understand exactly what you want to build before you buy a machine, because it may not do what you think it does.