I’m reading more about the concept of metamaterials, and believe this is a lot more important than I imagined.

But first, what are “metamaterials”? They are simply 3D objects that involve ingenious internal structures that allow a larger scale object made from them adopt different engineering properties than if the object had been made with the same material without the internal structures.

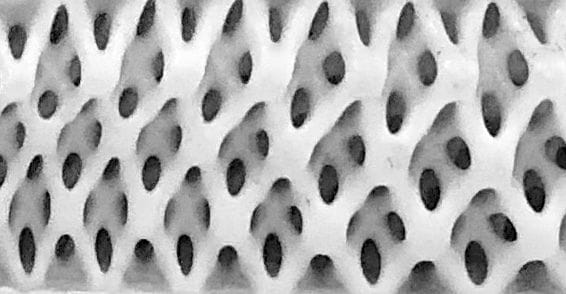

An example might be this lattice, which we’ve written about a lot recently. It’s a section of Carbon’s 3D printed Adidas midsole for their FUTURECRAFT 4D shoes.

This lattice is made from a strong material, but the lattice structure allows it to bend and flex. By varying the amount of structure in each zone, the object exhibits different amounts of flexure. It’s even possible to create a kind of “flexure gradient” by continuously varying the structures.

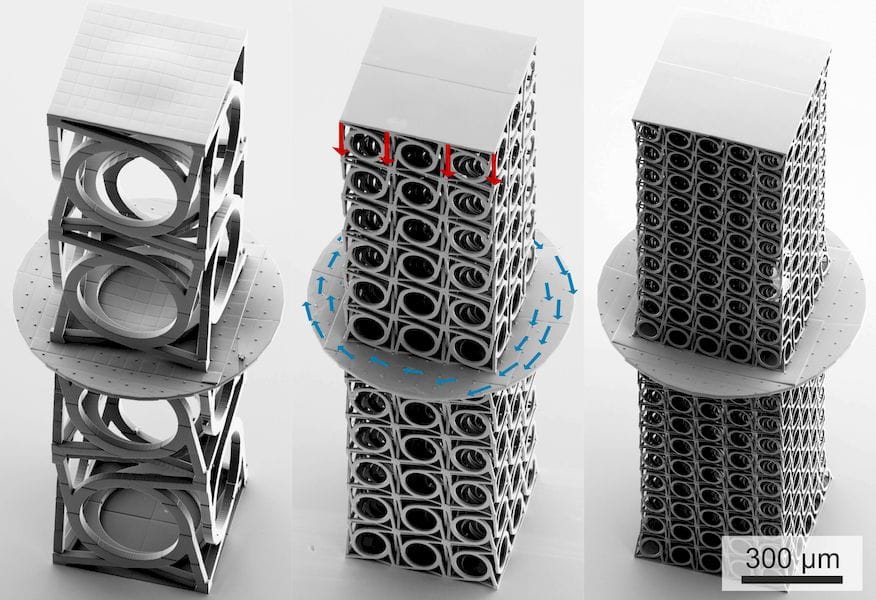

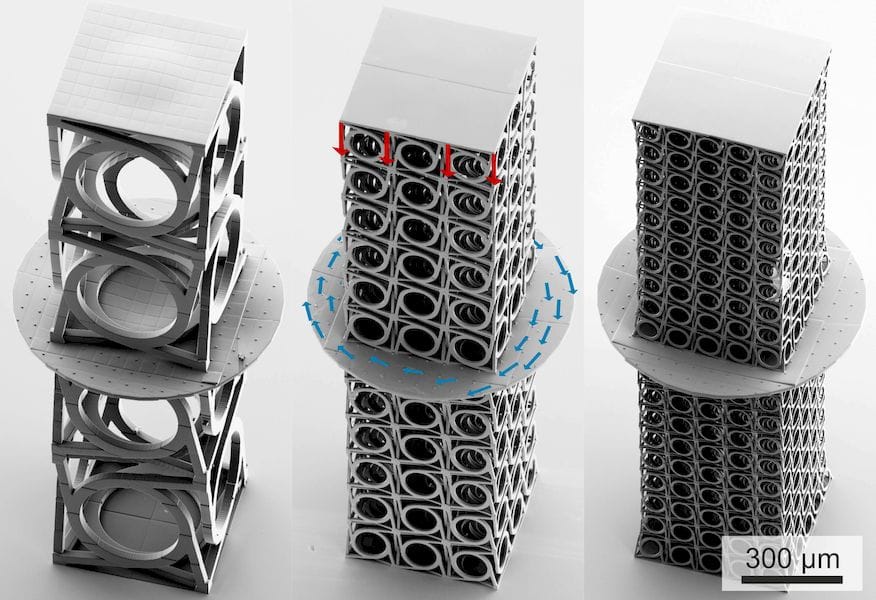

Another example might be the highly unusual 3D prints shown at top, which are specifically designed to twist when under stress. They were devised by researchers at the Karlsruhe Institute of Technology and the Université de Bourgogne Franche-Comté and produced using a Nanoscribe microscopic 3D printer.

I think you get the idea here: by creating ingenious internal structures, you can make “materials” that have never existed previously. In effect, these structures are almost like machines that produce desirable engineering results. And like machines, there is no limit to the types that could be envisaged.

What would you do with a component that twists as it is compressed? I have no idea, but I am certain there is or will be an application for such a thing. It may even be a usage no one has imagined yet.

And the same can be said for any of the other future metamaterials that are no doubt being designed in research labs around the world.

It’s possible there may be standard styles of metamaterials, such that they could be found in libraries for use by designers when creating futuristic items. That’s a long way off yet, but when it happens, it would literally be as if someone “found” an enormous supply of previously unusual materials.

Imagine the creative work designers could perform if unleashed into that world!

Today’s 3D printers, particularly the higher resolution equipment that can resolve such structures in strong materials, such as several SLA or SLS systems, make all this possible.

Once again, we have the hardware well ahead of the software. But that’s only a temporary phenomenon, as the software makers will catch up. Once they do, all this could really happen.