Last week Onshape released possibly the most major update since launching out of beta.

This week they introduce “Parametric Modeling 2.0” on the 30 year anniversary when parametric modeling software came screaming onto our screens.

I think it’s important to point out up front that, though I like the idea around Parametric Modeling 2.0, this is more than reviving and redefining a worn, old 3D design term. What’s more important is this — the features that define Parametric Modeling 2.0 differentiate Onshape from any other CAD tools.

What are these features?

- Configurations

- Standard Content

- Multi-Part Design

- Managed In-Context Design

- Simultaneous Sheet Metal Tools

- Custom Features

They’re not completely different features, but they are features reworked to help us as engineers and designers work better. And if you’ve used any of them, you’ll wonder why it wasn’t ever done like this before. Let’s take a look.

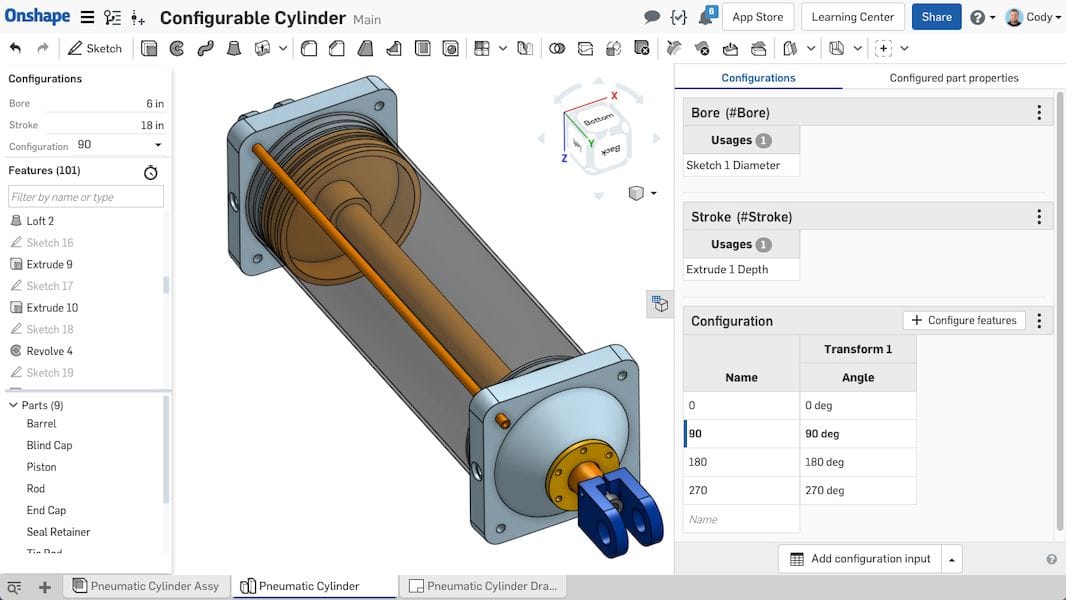

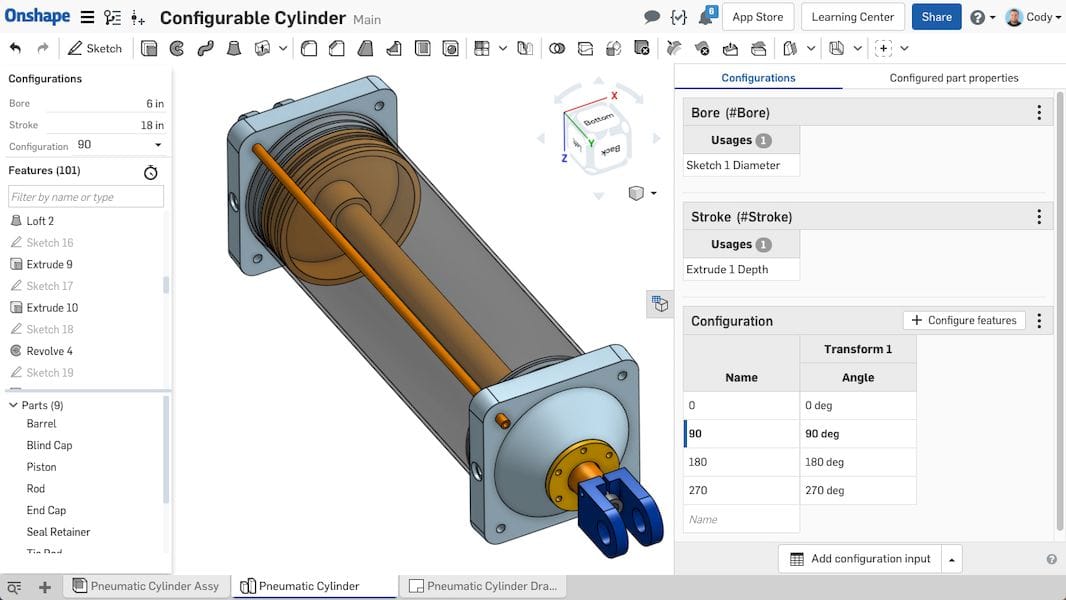

Configurations. Done Right.

How could you build out multiple configurations parameter differently than how it has been done? Here’s how Onshape explains it on their blog:

Other CAD systems require all configuration options to be represented in a single table with entries for each conceivable permutation, which in some cases can lead to hundreds or thousands of rows in that single table. As configurations get more complex with more options, that table grows exponentially – making it virtually impossible to understand, troubleshoot or manage.

If you’re like me, you know those CAD systems, and you’ve built out MASSIVE spreadsheets of configurations – getting extra points for color coordinating rows and columns, of course. They were a thing of beauty, AND SIMPLY SOUL SUCKING. Though lathering yourself in the time-absorbing suds of spreadsheet bliss sounds exotic, using them to build large design configurations is a time-consuming and file size increasing pain. They continue:

Onshape lets you build complex families of parts by creating separate small tables for each set of independent configuration options. This dramatically reduces the number of required table rows and cells. No more monster tables. For example, in file-based CAD, a simple bracket with 5 lengths, 5 heights and 5 hole patterns would result in an enormous 375-cell table to manage in a clumsily embedded Excel spreadsheet. In Onshape, this same configuration results in 3 tables of only 5 cells each and is edited with a native intuitive user experience.

In other words, standard, single parameter configuration are similar to building your typical configuration table, but when you add other parameters (nested or sub-configurations), new tables are added for each parameter and a list of configurations, a feature/state toggle checkbox or a variable that creates configurations based on inputs or that can be used to define other configuration values. And, when inserting a configured model into an assembly, you get option selections, not a list of hundreds of parts to choose from.

Read the rest at SolidSmack.com