The swiss-army knife of 3D printing has been upgraded.

Meshmixer, Autodesk’s free utility for all things 3D printing, has been upgraded to version 3.4.

The company has been incrementally improving the free utility for years now, ever since they acquired it in 2011. To their credit, Autodesk has not only maintained the highly useful utility since then, they have also continued to offer it to the public at no charge.

Meshmixer, if you don’t know, is able to import 3D models and perform a number of adjustments to them, such as resizing, cutting, repairs, and much more. You can even create a 3D model from scratch using their basic objects, but this is not used nearly as often as their modification functions. I typically use Meshmixer to chop larger 3D models into parts for printing in smaller volume 3D printers, for example.

What’s new in Meshmixer 3.4? There’s a couple of things as well as the usual “miscellaneous bugs fixed”. One is mildly interesting, but the other could lead to something important later.

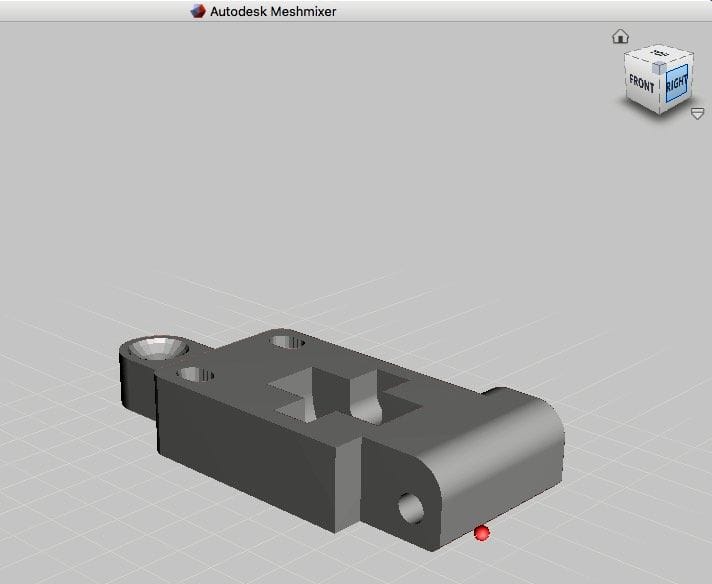

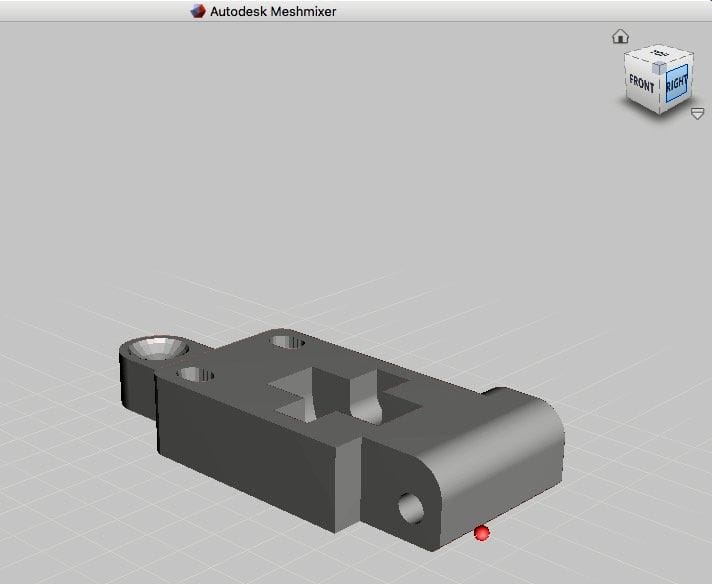

First, they’ve added Autodesk’s “ViewCube”. This is a icon that sits in the top right of the screen and provides a way to easily manipulate the camera position of your view of the 3D model.

You can spin the ViewCube for arbitrary views, but at any time you can click on a side, corner or joint of the cube to instantly orient the view to that angle. This is quite useful to restore a sensible view after much twirling. I also find it very useful when doing my model cutting, as you can quickly shift to a “straight” view of the model for accurate slicing.

The second major change in Meshmixer 3.4 is the addition of .3MF support.

3MF is a new format for 3D printable models, which we’ve described previously. The format is vastly superior to plain old .STL in many ways. Here is a list of some of its features:

- An XML package of informational components, rather than a “single file”

- Interoperable, at least potentially, between participating vendors

- Images of the 3D model for thumbnail purposes

- Digital signatures to ensure the package has not been tampered with

- Embedded textures to color the model surfaces

- A “Print Ticket” contains default information about intended printing configuration

- Consistent definition of top, bottom, left and right

- List of resources that could include, for example, different materials (and colors)

- Handles concept of multiple components comprising one build operation

- Requirement for “solid” 3D models that have manifold edges, consistent triangle orientation and direction (meaning a valid 3D model)

- Rules for how intersecting meshes should be resolved

What makes this announcement interesting is that it knocks down another barrier to .3MF adoption. One of the reasons .STL persists is because you can assume it is usable on whatever 3D printing hardware and software in your workflow.

Unlike other industries where a single piece of software might encompass all your workflow, use of 3D printing frequently requires multiple pieces of software, and you must chain your work through each system or service. If any of them don’t support .3MF, you probably won’t use it.

Meshmixer, being an important tool in many peoples’ workflow, has in the past disqualified 3MF from the workflow.

But now that is no longer the case.

Could this be the turning point for 3MF, where there are enough applications and hardware using it to cause many people to begin switching over?

I’m not sure, but I think I’ll give it a try. Will you?

Via Meshmixer