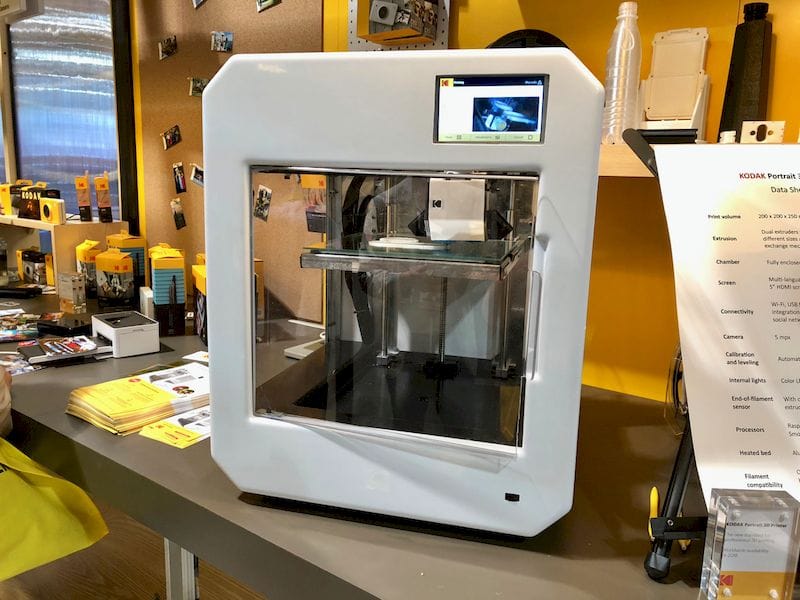

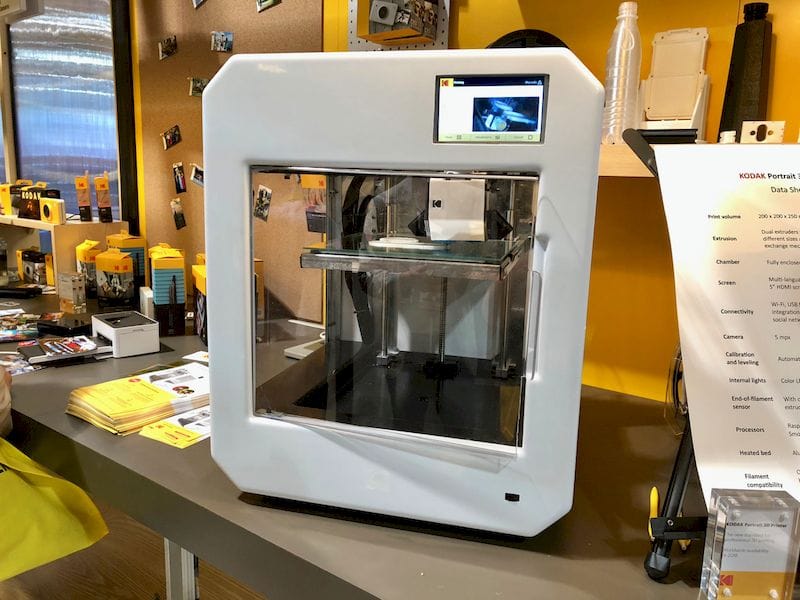

At CES we were able to get a close look at the new Kodak Portrait professional desktop 3D printer.

The Portrait 3D Printer, which is made by Argentina-based Smart International under the Kodak brand, is definitely not a consumer-style 3D printer. This machine is very well targeted for professionals seeking high quality prints and good reliability.

The machine is in fact designed around those principles.

As you can see in the top image, it’s fully enclosed to prevent dust from entering and capture heat for more consistent 3D printing.

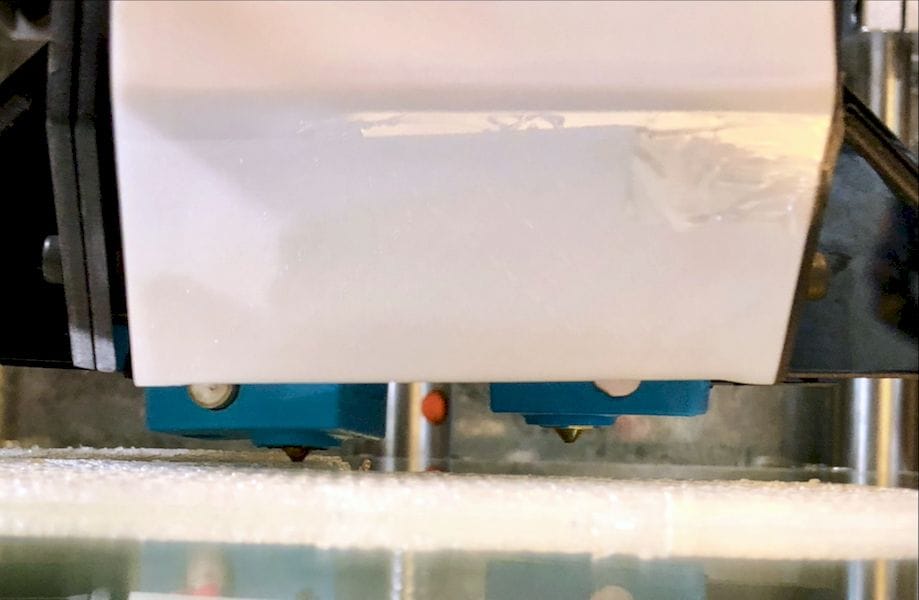

It’s a dual nozzle machine, enabling the use of alternate support material. While they do offer HIPS as a support material today, it sounds like they are working with their materials supplier to develop a water-soluble material in the very near future.

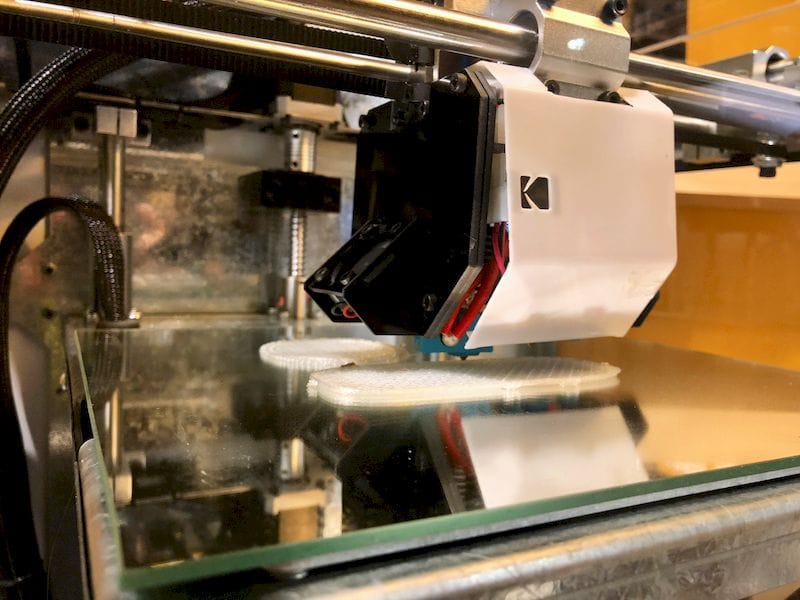

The method of dual extrusion is very interesting. Rather than using the standard parallel-mounted hot end approach most other machines employ, the Kodak Portrait instead has a nozzle tilting mechanism shown here. The inactive nozzle is lifted slightly out of the way while the active nozzle deposits material.

This is a critical feature, as the inactive nozzle inevitable gets tangled up with the stray print material and frequently causes print failure on dual nozzle machines. The Kodak Portrait should avoid that issue entirely with the tilting nozzles.

The machine also includes an out-of-filament detection system, which will pause the print and permit reloading of new material.

Otherwise the Portrait employs a full E3D extrusion system, meaning you can take full advantage of the E3D ecosystem to exchange nozzles, for example.

Electronics are interesting on this machine. Rather than using an Arduino board that most machines use, they have a powerful 32-bit Smoothie board that should provide for rapid printing.

For the fancy touch screen interface, they’ve embedded a Raspberry Pi. But they do not run Octoprint; instead they’ve developed their own system that should be more easily learned by new users.

The Kodak Portrait 3D printer also includes a webcam and software to integrate remote operations through a standard web browser. They even have a method of providing for “personal profiles” that should make this machine very attractive to higher level educational institutions and business workgroups.

Prints made on the machine appeared to be of very good quality, regardless of the material used. It can produce items that fit in its 200 x 200 x 250mm build envelope.

Kodak’s material availability is very good, with multiple thermoplastics available from them. They do permit the use of third party materials, but of course recommend using their own carefully crafted materials for best results.

The spooling system is interesting. Their materials are shipped in sealed containers as shown here.

To deploy them, you insert the spool into another sealed container, which mounts on the back of the unit, or can be standing beside the machine. Inside the sealed unit is a pocket where you can place drying agents, thus ensuring your materials are always appropriately dry: sealed sales container directly to sealed spool mount.

The Kodak Portrait 3D printer is quite impressive, and should be a good option for professionals. It’s shipping in March at a price of USD$2,799.