We bumped into Ethereal Machines, a Bangalore-based 3D printer manufacturer and were surprised by the varied nature of their product line.

Their genesis story is typical: they were providing 3D print services to a number of companies, but found the constraints of existing equipment to be too difficult. They decided to begin designing and producing their own equipment, which led to their current product lineup.

The startup company now offers a number of 3D printers that address the prototyping and manufacturing sector. While they do offer a basic dual-extrusion professional desktop 3D printer, the Ethereal Ray, we were more interested in their other products.

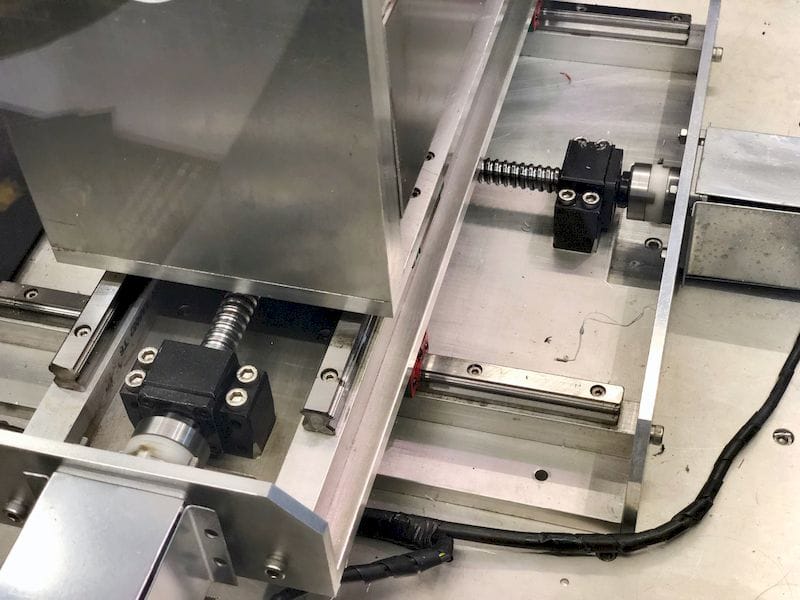

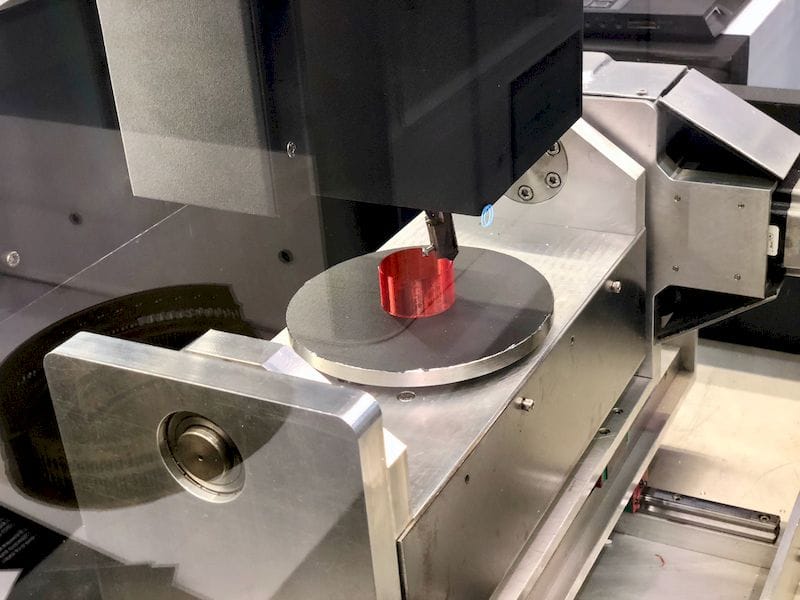

In particular, they offer the Ethereal Halo, which is a hybrid 5-axis CNC and 3D printer. This unusual machine can CNC mill wood or even metal, but also it can 3D print thermoplastics.

Changing the mode of the machine is said to be straightforward, requiring only four bolts to be removed and can be done within minutes.

The ability to CNC mill is, of course, very useful, but Ethereal Machines allows hybrid operations. For example, you could CNC mill a block into a shape, and then 3D print thermoplastic on top of that newly-milled surface.

Another very exciting capability that becomes possible when 3D printing with a 5-axis hot end is the elimination of support structures.

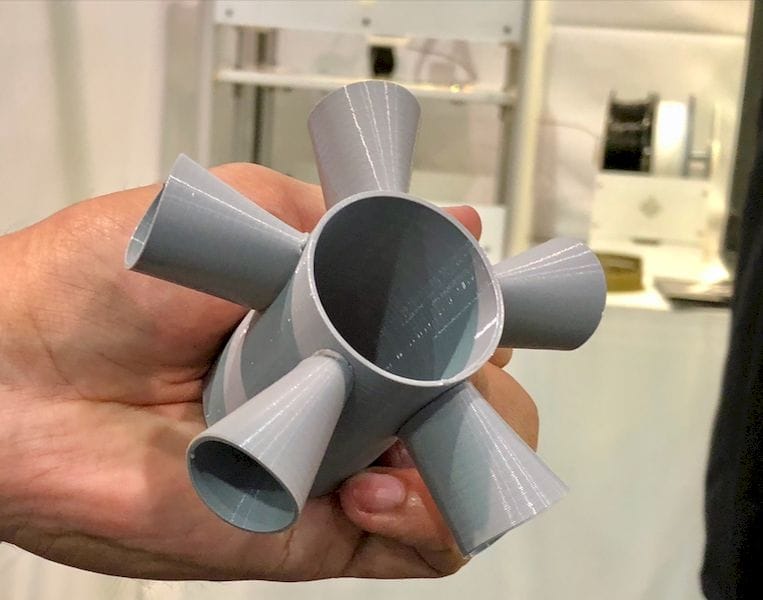

Here we see an example print Ethereal Machines created. Note the layer lines, showing clearly how this part was printed in different orientations to eliminate support structure requirements.

It’s clear this part was produced without any support structures; the CNC axes simply rotated the print in such a way to present the extrusion surface upwards. No support required!

We’re told the Halo will sell for approximately USD$20,000, which most definitely puts it out of the range of any consumer, in spite of their slogan “Ethereal Halo is the world’s first consumer oriented 5-axis 3-D printer and 5-axis CNC Router.”

Nevertheless, it joins a select few other companies making 5-axis 3D printers. I’m wondering if this technology will eventually become the standard for 3D printers of the future, as it is so versatile.

Oh, and they also market a 3D concrete printer!