This week’s selection is the carefully designed Hand-Screw Clamp by industrial designer Jacob Stanton.

Chicago-based Stanton wished to explore the idea of designing 3D printable parts that are capable of performing significantly better than typical 3D printed parts. If successful, he believes this could open up a new world of printable mechanical designs.

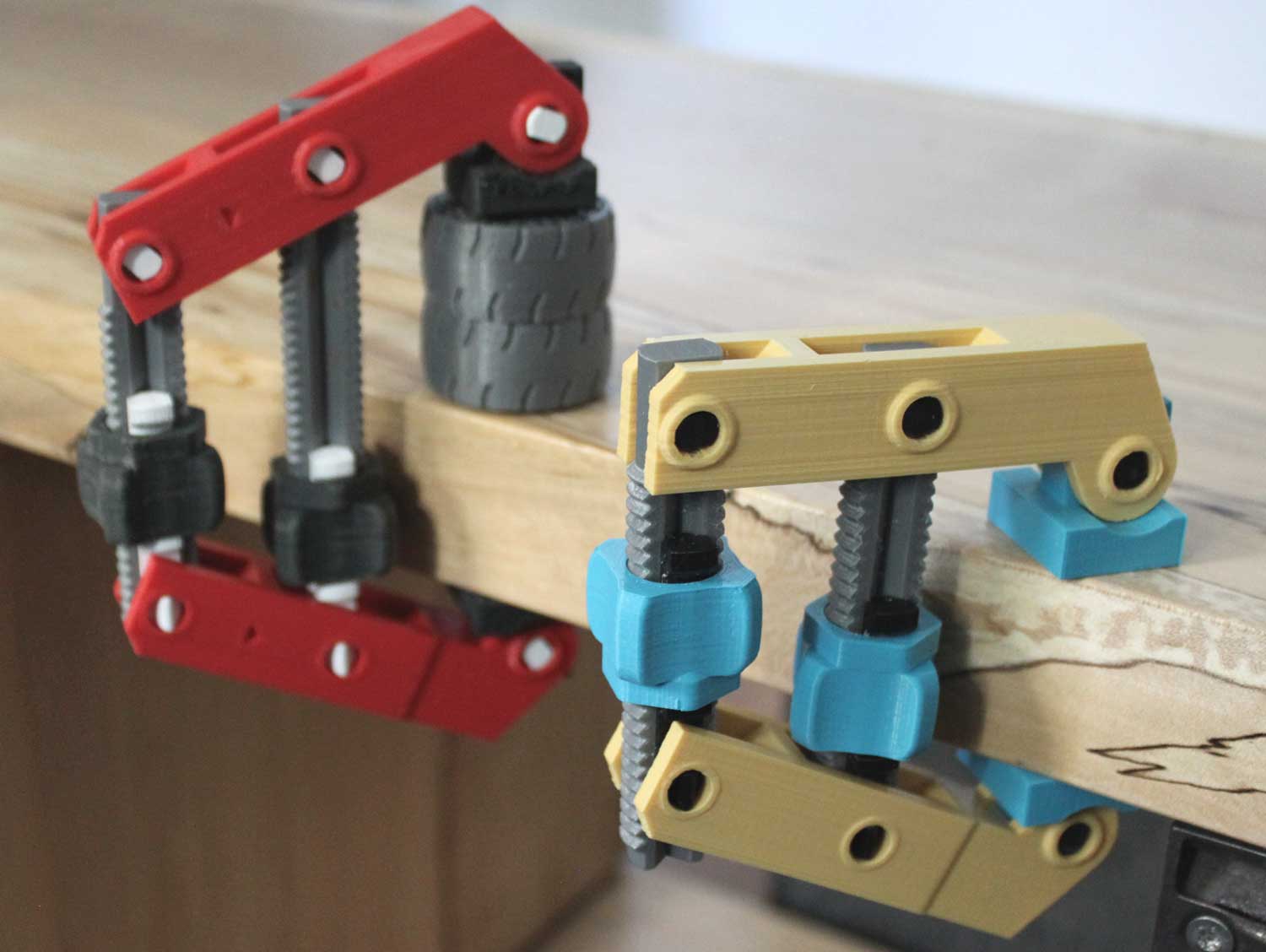

Stanton realized that while there are large numbers of bolt mechanism available for download, they all suffer from a structural problem, best illustrated by this diagram:

As you can see on the left, if bolts are printed vertically they will inevitably fail at the layer lines, precisely where the stress of bolting will occur. Ideally you’d want to 3D print the bolt sideways so that the extrusions are align with the stress more optimally, as shown on the right.

However, printing a bolt sideways could produce a very lousy surface on the bottom, as it will be spattered with support marks, making it difficult for a good fit with the nut.

Stanton thought of designing a bolt that was flat on one (or really two) sides, making it easy to print sideways and thus have far greater strength.

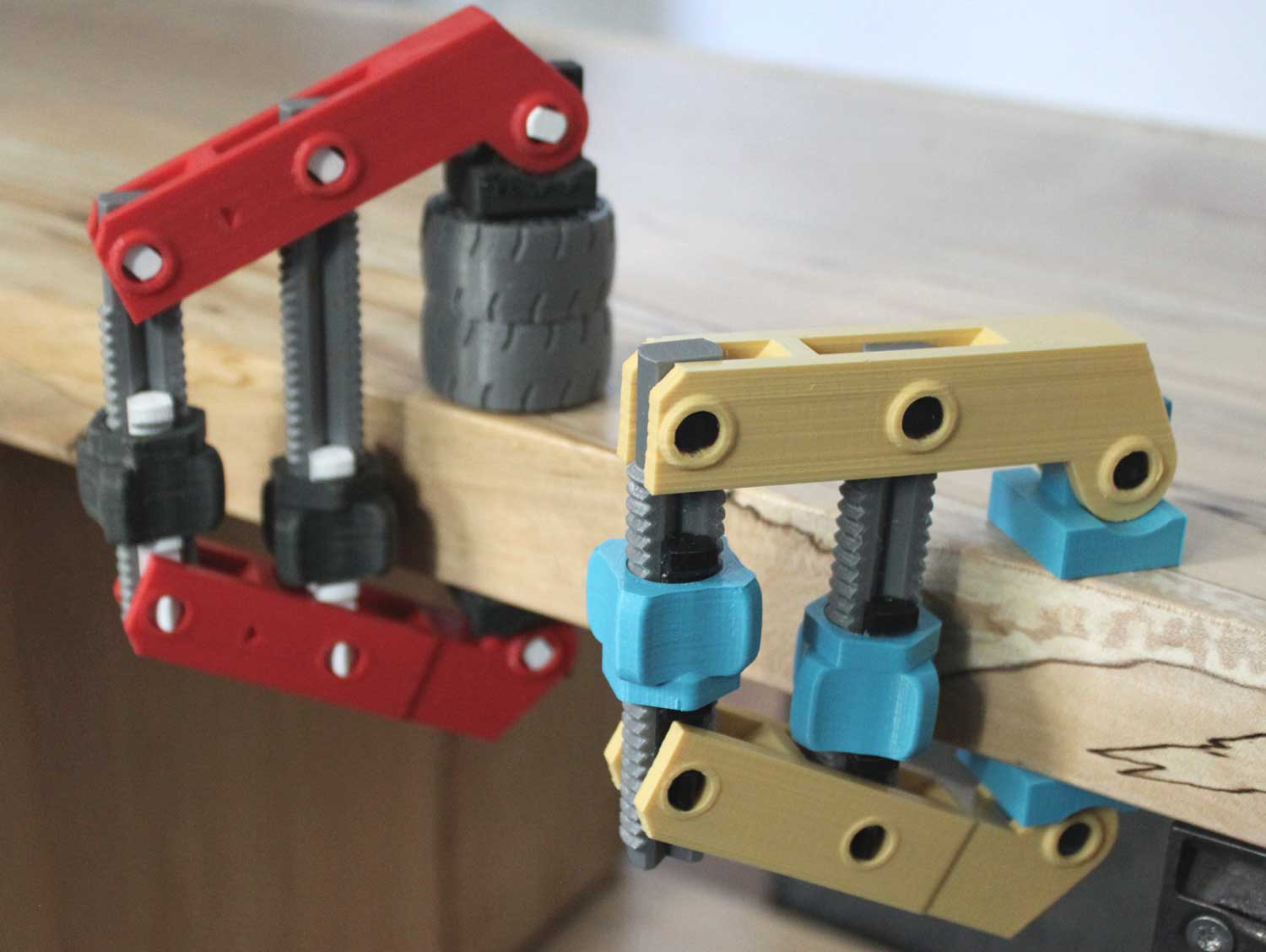

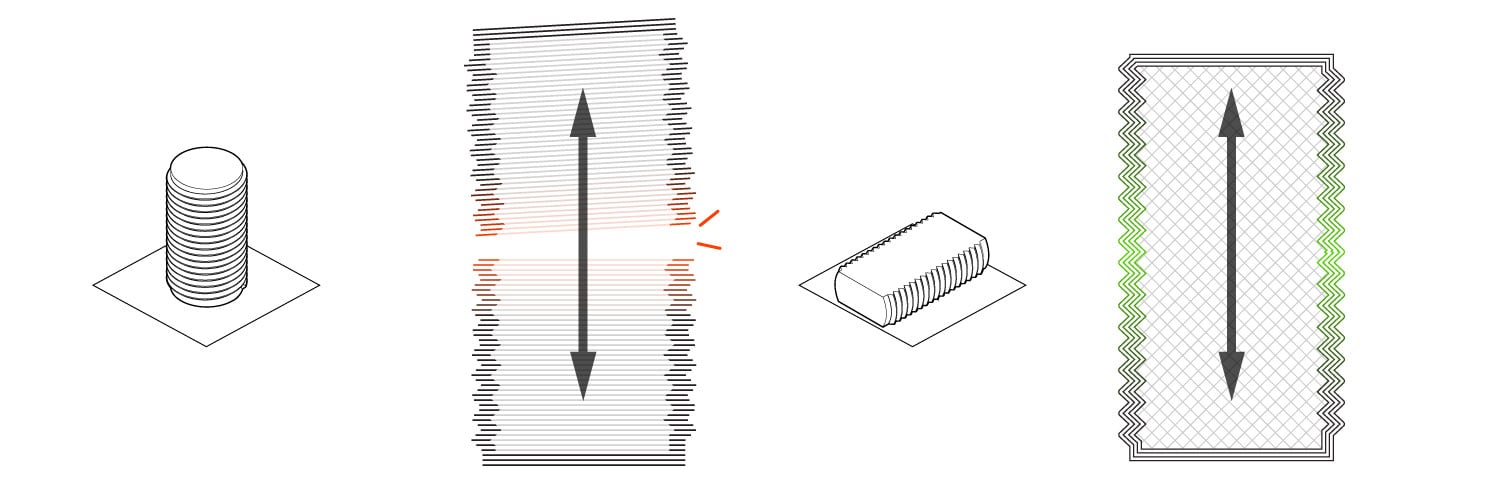

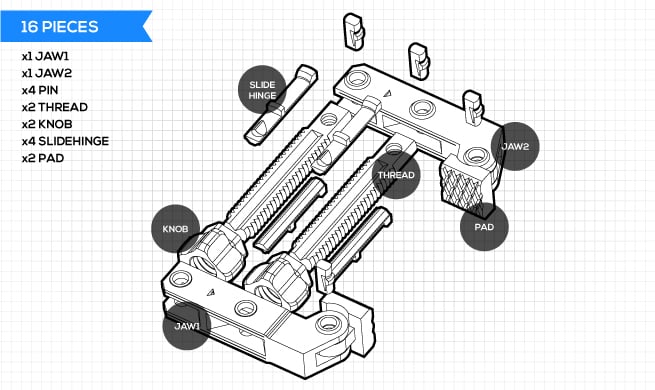

As a demonstration of the capabilities of this bolt design, he composed the Hand-Screw Clamp mechanism.

The result, printed in PLA at 100% fill apparently provides a rather strong clamp – although clearly not as strong as your typical metal clamps. Stanton explains:

I printed everything with standard draft settings, in PLA. Through testing, I found that the small “SlideHinge” parts are always the first things to fail. They break off at the very tip of the end that captures the rotating knob. So if you wanted it stronger with minimal changes, you could print the “SlideHinge” part solid.

This is tricky to assemble. The design intention wasn’t to make a simple clamp. It is more of a demonstration of a 3d printed mechanism to make this special type of clamp.

Also, adding some sort of wax from a candle / soap / etc. will help make clamping much smoother.

I’m very interested in this concept, because it twists the idea of a standard part (a bolt) into a new vision that’s compatible with 3D printing technology. This type of bolt should become a standard for use in 3D printing projects.

And that leads to another question: What other common mechanical parts might have a more optimal 3D printed counterpart?

Via Jacob Stanton and Thingiverse