The new wave of 3D metal printing continues, and one of the most interesting players is Germany-based AIM3D.

The startup company began with an idea a few years ago in 2014 for using standard metal injection molding pellets (MIM pellets) instead of powder or filament for 3D metal printing. If this process works for injection molding, why could it not for 3D printing?

The MIM market is enormous and worldwide. The idea is to melt pellets of metal powder and binder (but mostly metal) and forcibly inject them into a mold. Once cooled, the mold is removed to reveal the “green” part, a combination of polymer binder and metal powder. This green part is then sintered in a furnace where the binder is removed, leaving a solid metal part.

Could this process be done on a 3D printer? While the sintering process would be identical to the MIM process, the act of 3D printing with pellets is another matter. There is a reason almost all desktop extrusion-based 3D printers use filament: it provides an easy way for the machine to precisely meter out material through the hot end. Pellet extruders have been very rare, and typically used only in unusual situations.

One situation where I’ve seen pellets used previously is in very large-format 3D printers, such as the Stratasys Infinite Build Demonstrator or the WASP large-scale delta machine.

Both of these systems used pellets because their enormous prints would be outrageously expensive if using standard filament, which can cost 10-20X more than industrial thermoplastic pellets. In fact, filament is almost always made FROM those same pellets, so using them directly takes a step out of the cost equation.

However, it is very challenging to make an extruder that can effectively use pellets, but that seems to be what the folks at AIM3D have done. While it may appear to be simply a 3D pellet printer, the implication is that you can use any of the thousands of existing MIM pellets as input material, and you are not constrained to the relatively pitiful selection of 3D printer-certified filaments.

And pellets are far cheaper, costing perhaps USD$20 per kg or less.

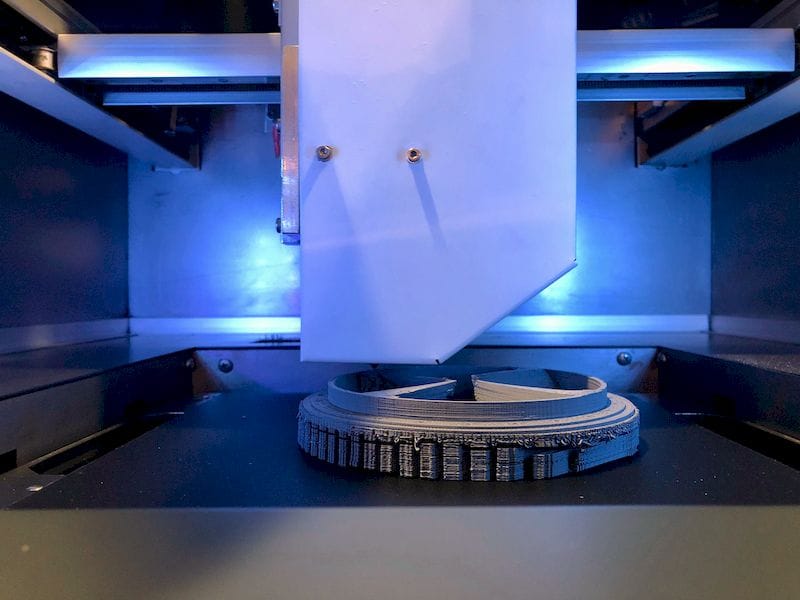

AIM3D’s ExAM 255 machine implements their concept brilliantly. It accepts MIM pellets as material and produces what’s called “brown” parts. These are parts infused with binder.

The brown parts then undergo a second process, outside the 3D printer, to remove 98% of the binder. This maybe done thermally or through washing or immersing in chemicals for catalytic reactions. It all depends on what particular material is involved.

Once “cleaned”, the brown part now becomes a green part, which can be sintered in a furnace to remove the remaining 2% binder and fuse the metal particles together. At the end of the process you have a metal part, made a relatively low cost. Much lower than powder-bed/laser processes and even lower than binder jetting approaches.

But here is the really interesting thing: A metal workshop that already uses a MIM process need only add one of these machines and it will fit directly into their pre-existing workflow! Their MIM injection molded brown parts will be procedurally identical to those produced by the ExAM 255. They simply send the brown part through their normal process.

This means that a metal workshop could almost instantly add the capability of 3D printing metal parts at a relatively low cost of entry and have similar operational costs to their normal part production process.

Of all the new inexpensive 3D metal printing processes, I suspect this one may be the most successful, as it is designed to fit into the needs of their customers with great ease.

However, you’ll have to purchase the ExAM 255, which we’re told will be priced near €90,000 (USD$107,000).

If that sounds like a big number, it isn’t. Alternative approaches can be vastly more expensive, particularly from powder-bed/laser vendors. Even Desktop Metal’s system would be more expensive than AIM3D’s.

However, Desktop Metal and others have vastly more cash than startup AIM3D, so they will likely get more attention, at least for now.

AIM3D will have to build up their operations and in particular prove their value by demonstrating how straightforward it is to integrate their concept into existing metal workshops.

We’ll see how well they do in 2018.

Via AIM3D