A new project by 3D Systems made me realize something interesting about 3D metal printing.

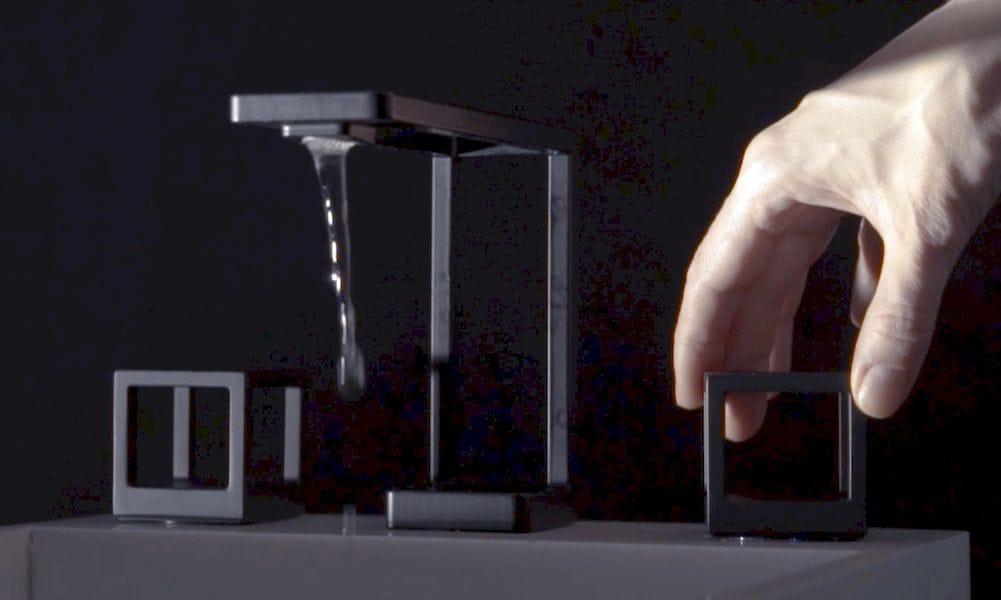

The project involved creating a very unusual kitchen faucet design inspired by a cube, designed by Kallista and manufactured by 3rd Dimension, an Indiana-based 3D metal printing service. The hot and cold knobs themselves are hollow cubes, in fact just the outline of a cube. While you can easily imagine knobs in that form, having the faucet itself is a bit more complex.

The faucet design is complex and cannot be made using conventional manufacturing approaches, thus the need for 3D printing technology. 3rd Dimension used a 3D Systems ProX 320 to produce the raw parts.

While most of this announcement is keyed towards turning on metal workshops and designers to the benefits of 3D metal printing (and they should be turned on), there was one interesting aspect I noticed.

3D Systems explains the post processing involved in this project:

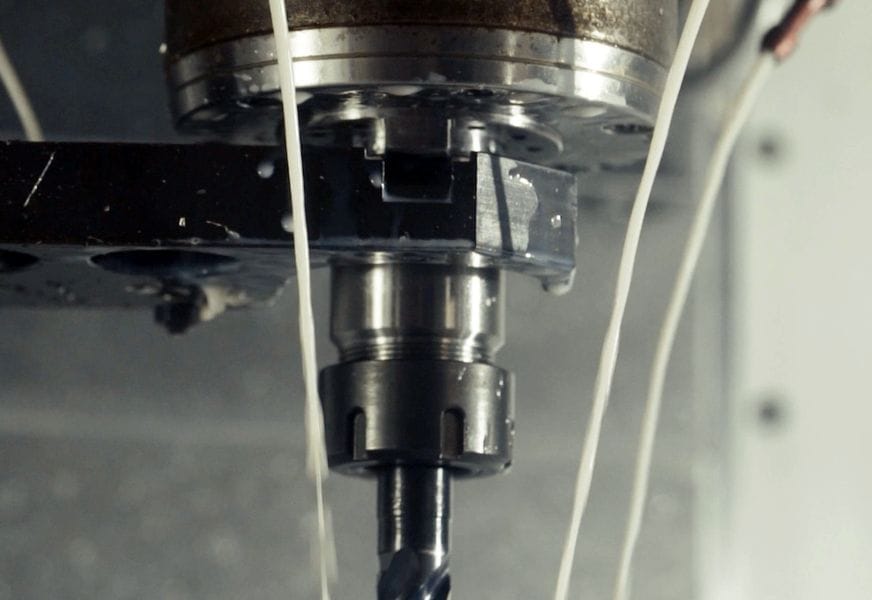

In this case the parts are removed from the build plate using EDM (Electrical Discharge Machining), then heat-treated to reduce stresses and tumbled for finish. They then undergo machining for the threading and tapping, and are sent to powder finishing in black. Having an in-house production specialist, or external contractor or consulting team to plan and enable these activities is key.

The Wire EDM machine is the commonly accepted method of removing 3D prints from the build plate – really, the part is literally fused of the build plate after printing.

Heat treating is also a typically required 3D metal printing post processing step, as it finalizes the crystallization of the metal particles at a microscopic scale. This adds strength to the part.

But after that we have a series of otherwise normal processes taking place, steps that would appear in many metal workshops, regardless of whether they employ 3D printing. We have tumbling, machining, threading, tapping, powder finishing. Those steps are completely understandable by any metal workshop.

Here’s the interesting aspect: it would appear that integrating a current 3D metal printer into a low-volume metal workshop should not be that big a deal. The 3D metal printer would produce a part that then follows through subsequent processing steps in the same manner as any other non-3D printed part. The technicians use the same procedures and equipment and require no additional training.

I point this out because there is a trend recently we’ve observed where there are forces trying to “get 3D printing into manufacturing”, where the barrier is that current 3D printers are typically designed in “standalone mode”, where a human operator is required. Thus such machines just don’t fit very well into a highly automated production line, where each step is automated into the next. Adding a typical manually operated 3D printer would “break the line”, and destroy the efficiencies of the production system.

But that’s an effect one sees only at higher levels of production. At lower levels, where the equipment is already operated manually – as typically occurs in smaller workshops where custom projects take place producing lower volumes of parts.

In those workshops, adding a 3D metal printer is a far simpler matter, and requires only a couple of people to be trained on operating the machine. Oh, and of course someone will have to know how to generate the 3D models, but often metal workshops are receiving those from clients and don’t always make them in house.

In spite of the efforts of some to address the huge mass production market, there is still the need for smaller operations to take on 3D metal printers.

Via 3D Systems