Mass Portal continues to experiment with advanced 3D printing techniques.

The Latvian company has made a name by developing highly regarded desktop 3D printers that can produce extremely accurate prints. Some of the best filament extrusion prints I’ve seen have come from Mass Portal equipment.

Recently they’ve been experimenting with an array-style manufacturing system called the Dynasty, which has now become an official product. They also have been developing a sophisticated and integrated filament dryer system.

They’ve had a history of doing interesting experiments to improve the quality of their equipment and its results. Now, their experimentation continues with not one, but THREE different experiments we viewed at FormNext.

One of the new experiments is a tool-changing system for delta style 3D printers, of which Mass Portal is quite expert, having built them for years now. We’ve previously seen a few systems that offer tool-changing for cartesian-style motion systems, but not for delta machines.

This should allow future Mass Portal systems to use a much wider variety of materials and tools, possibly including paste extruders, CNC milling heads or even laser engraving, all in the same machine.

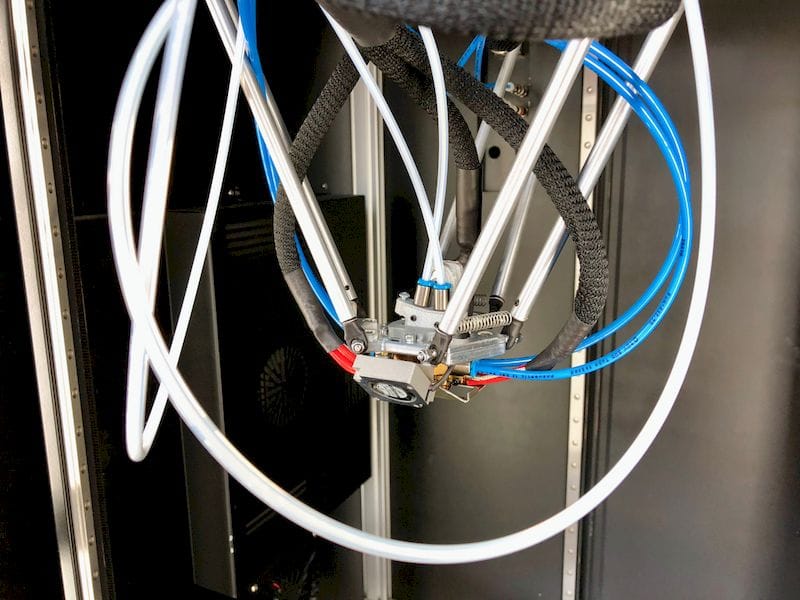

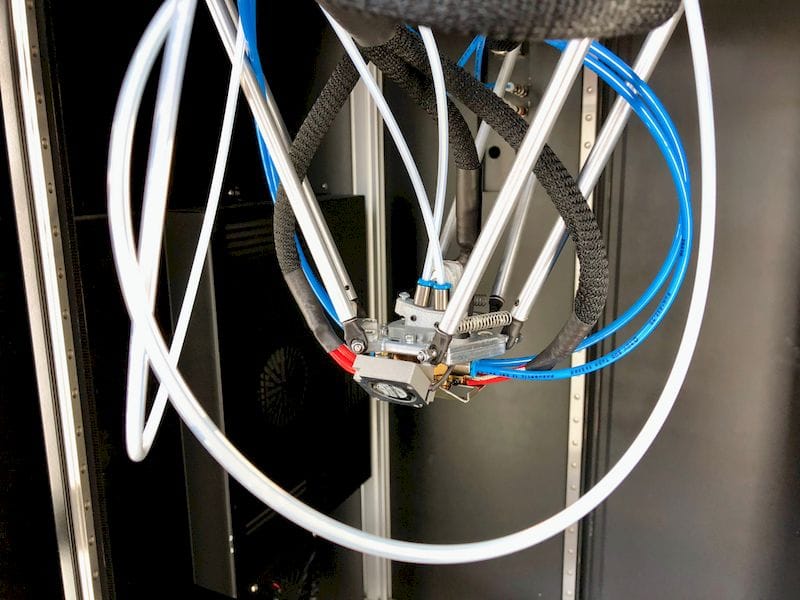

The second innovation is a powerful four-extruder delta tool head system (see image at top). This will permit a single delta nozzle to 3D print in four different materials (which could be colors or different thermoplastics). Most importantly this could allow an operator to 3D print dissolvable support material during a print, enabling the easy creation of arbitrarily complex geometries.

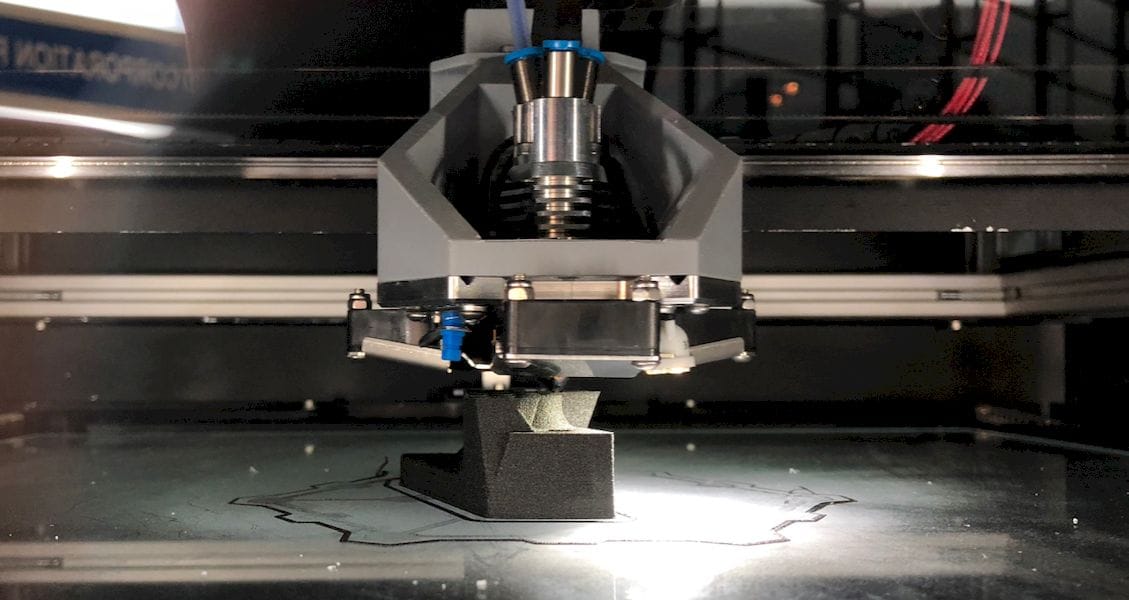

Finally, Mass Portal has introduced a surprising cartesian-based 3D printer. This, from a company that has made its name producing delta-style 3D printers for years. It’s not a clone or rebrand of another maker’s device; Mass Portal has developed this machine all on its own. So far it has no name and is only a prototype.

But why do so? There’s evidently an issue with magnets at higher temperatures, and magnets are what holds the delta framework together. This suggests they’ve observed quality issues when developing higher temperature delta style equipment to compete with the rapidly increasing number of alternatives in the world of 3D printing these days.

Thus the need to move to a cartesian system, at least for higher temperature materials. I do suspect the company will continue producing delta equipment for lower temperatures for the foreseeable future, however.

We’re told all three of these innovations will become products and ship in January 2018.

Finally, it sounds like the company is also working on a number of other innovations that will surely appear sometime in the future, including a heated chamber, dual swinging nozzles for a delta style 3D printer and more.

Via Mass Portal