I’m looking at a new product that hopes to break into the 3D printer market, the alignG.

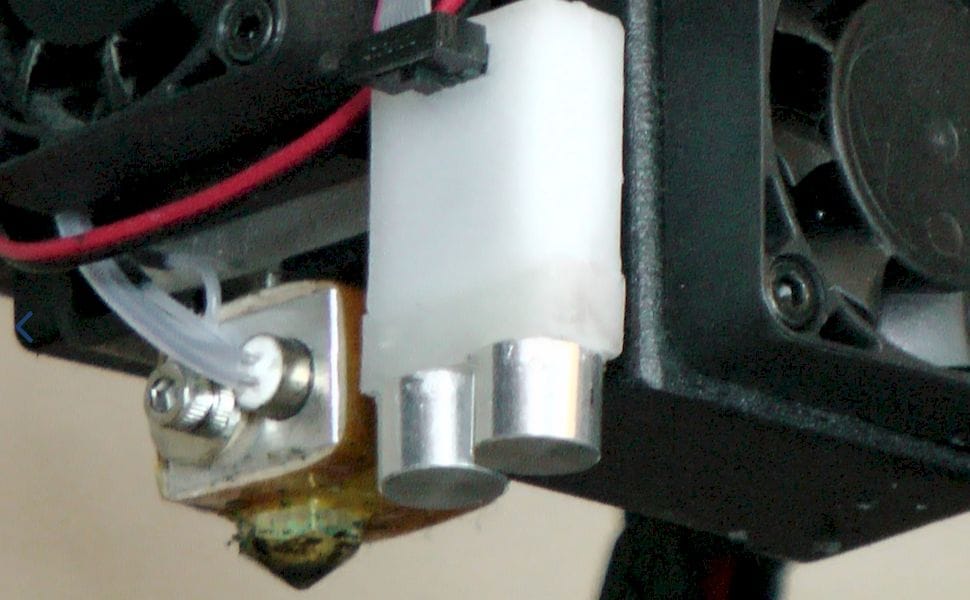

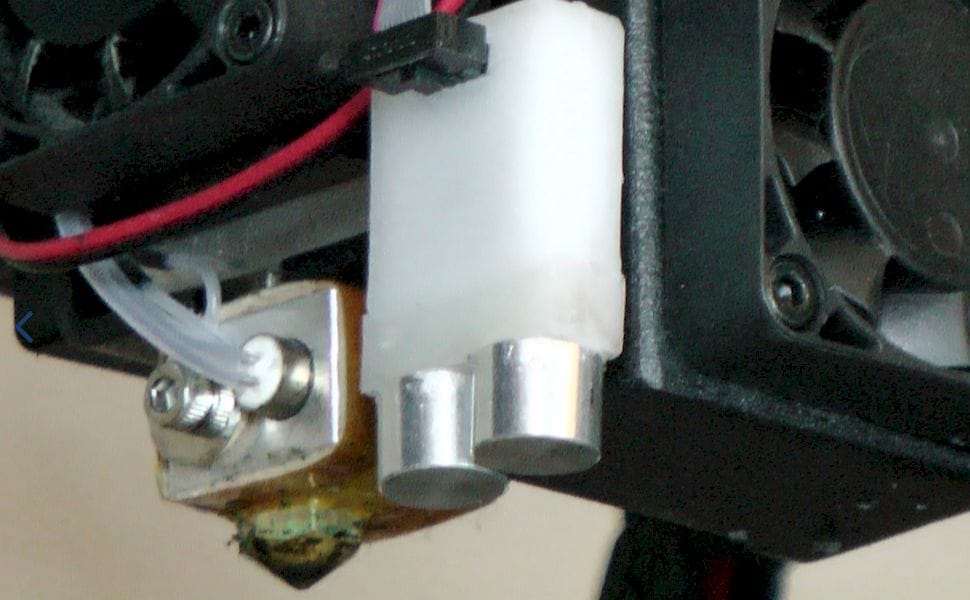

The alignG is a non-contact measurement unit that employs ultrasonic sounds to measure bed leveling on 3D printers, among other uses. It’s quite a sophisticated system and is provided in several different formats.

Automated bed leveling has now become a standard feature on any reasonable desktop 3D printer, and most systems that do so require a proximity sensor to effect the distance detection when measuring bed plate position. That’s what the alignG does.

The three models of alignG available are:

alignG-P, the most cost effective version, is a proximity sensor with precision of 2.5 micron (0.0001”) to replace for any 3D printer bed leveling sensor. alignG-P works on glass, aluminum, and polymer beds.

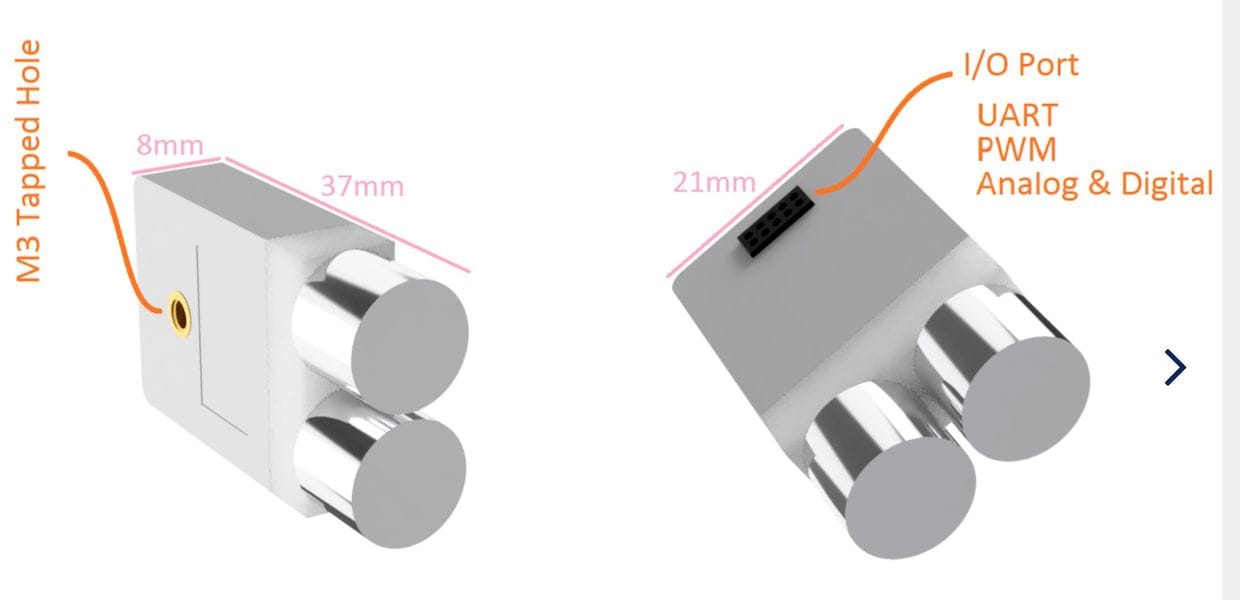

alignG-S, is a compact proximity & Distance measurement sensor with Digital and Analog communication port. alignG-S has a modular design; it comes with the base unit (alignG-S) and some external modules (Such as: Development Board, USB Module, Bluetooth, …) that attach to the base unit like the pieces of Lego. alignG-S has precision of 2.5 micron (0.0001”) in proximity sensing and precision of 25 micron (0.001”) in distance measurement. alignG-S is the only bed leveling sensor that simultaneously functions as a proximity sensor for auto bed leveling and distance sensor for manual bed leveling.

alignG-F, recommended to machinists and professional 3D printer users, is a professionally designed instrument with aluminum body, rechargeable battery, display, and high speed measurement mode. alignG-F is advanced by Doppler technology allowing for rapid measurement of distance. The instrument can even measure the cross-section of a rotating part. alignG-F can be used for distance measurement, alignment, backlash calculation, monitoring the run-out of the rotating parts, and many other applications.

As a component of a 3D printer, it won’t do the bed leveling itself. It must be combined with other features to effect leveling. These may be manually operated leveling mechanisms, automated tilting or dynamic software handling of uneven surfaces.

For those considering building a system using this sensor, it may be overkill, as the 2.5 micron (0.0025mm) tolerance level is far tighter than most extrusion machines could possibly achieve. I suspect this equipment is best suited for more advanced machines using non-extrusion processes that print in far higher resolution. At that level, the precision of the alignG sensors would make a big difference.

As of this writing, the alignG is not yet for sale, but they’re soliciting for early backers on a future crowdfunding campaign by offering a 25% discount and free shipping.

This looks to me like another startup, and as such one must scrutinize their offer carefully, when it arrives. Interested readers may wish to review our crowdfunding checklist before investing.

Via alignG