Researchers at the University of Washington have developed a new inexpensive communication system using 3D printed prototypes.

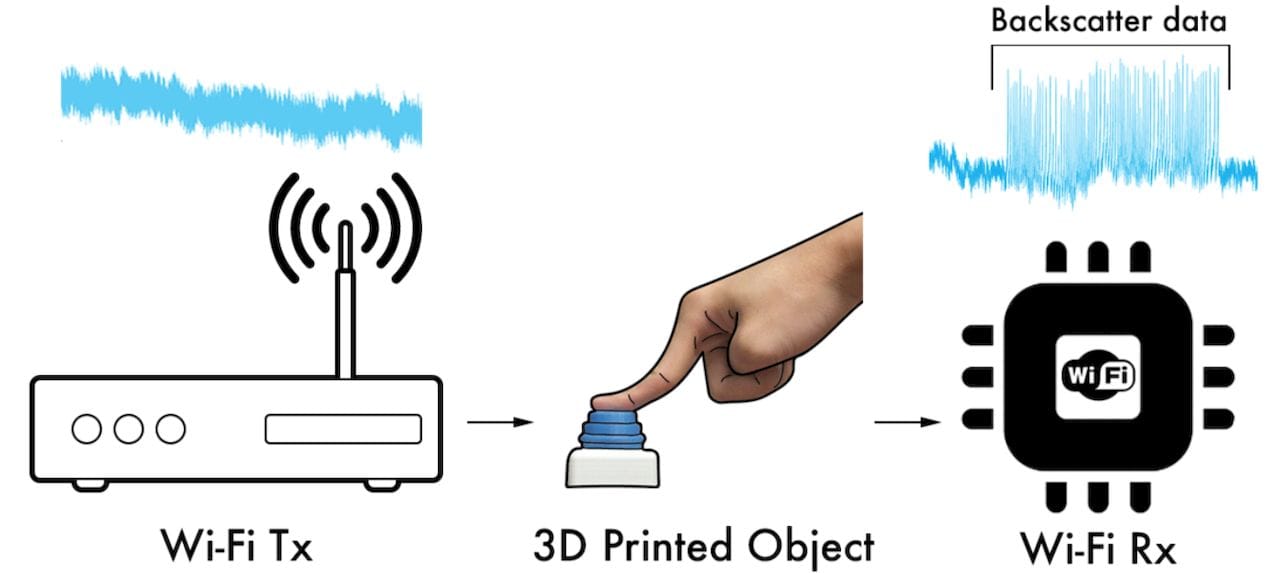

Their development is a method of allowing mechanical, non-electronic devices to participate in a WiFi network. It’s quite ingenious and could lead to an entire industry of components using the technique.

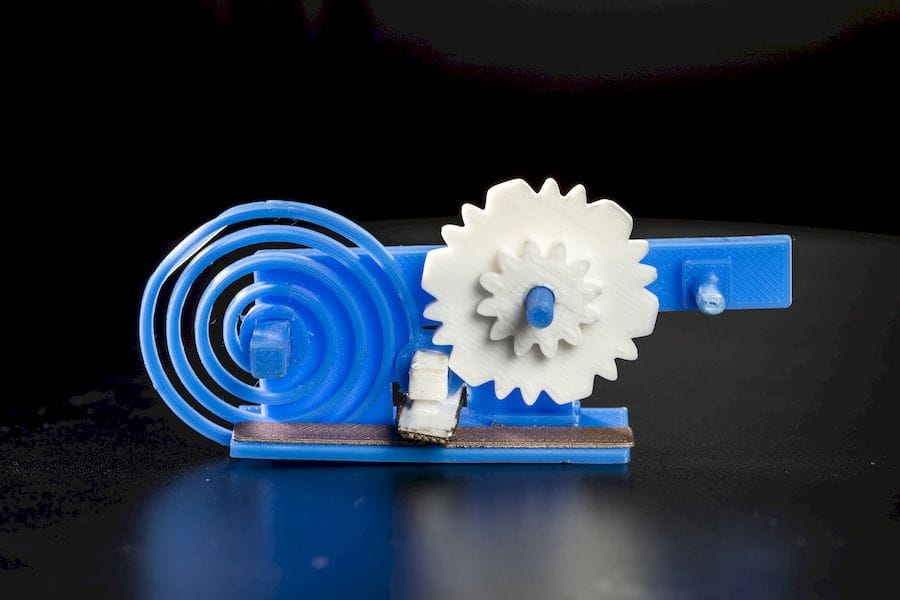

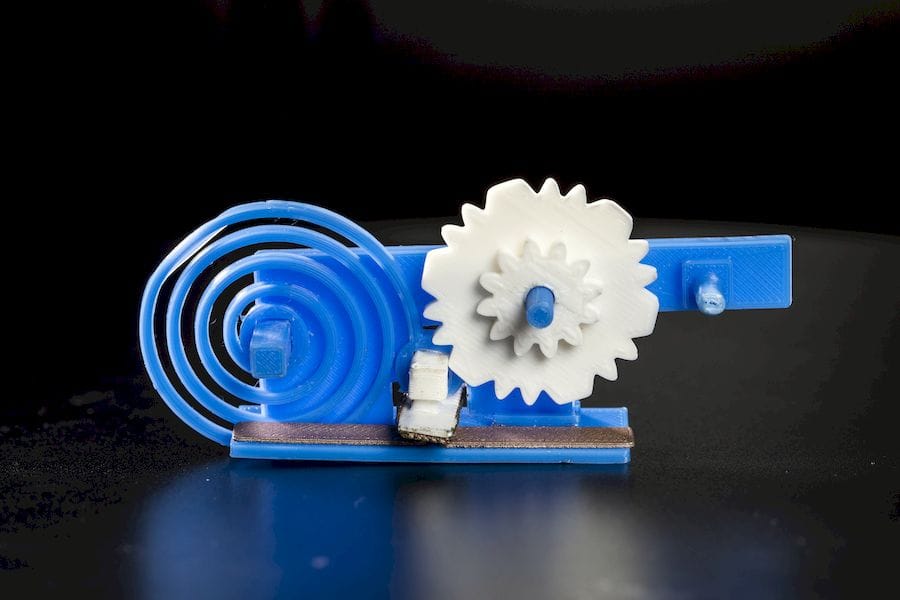

Their approach was to 3D print a series of mechanical devices in conductive thermoplastic, a material made with conventional thermoplastic combined with fine copper powder.

This copper actually reflects signals emitted from nearby WiFi routers, and this reflection can be detected by the router.

But then it gets a lot more interesting when the reflective object is in motion, because the reflectivity takes on a pattern that is derived from the object’s shape and motion. This too can be detected – and analyzed.

The researchers showed that these mechanical prototypes could indeed provide signals that might convey useful information to a central controller.

But what would you do with such a thing? The researchers developed several prototype applications, which may or may not fly. One involved a detergent container that would provide a signal pulse as the liquid was dispensed. This periodic signal could be used to track the usage of the fluid, and theoretically could re-order more when quantities are low.

Whether that particular system will be a practical thing remains to be seen, but what’s more important is that this concept seems to work.

I do have some reservations, however, as I could imagine a future environment with many such devices and their cumulative signal reflections would overlap each other and confuse any attempts at detection. But perhaps that’s a problem that can be solved.

If solved, though, we may see such simple-to-make devices become very widespread. Imagine light switches that require no wiring, for example, to control networked light bulbs. What other examples could be made? What might industry do with this capability? The mind boggles.

As for 3D printing, I do not think these mechanical signalers will be 3D printed in the future. While it is an excellent place to 3D print prototypes, I suspect the “real” production devices will be mass produced in much smaller form factors using traditional manufacturing techniques.

But we wouldn’t have gotten there were it not for 3D printing and the ability for innovators to rapidly try out a crazy idea. And make it not so crazy.