3D printers have quickly changed from new technology to manufacturing miracle to household toy — you don’t need much more than a printer and a computer to create amazing 3D items from plastic, metal or even glass.

Until now, though, 3D printers in the medical field were reserved for the creation of a very limited set of medical devices including prosthetic limbs and replacement joints.

New 3D bioprinters have become particularly advanced in recent years — and they could potentially change how we perform procedures like grafts and transplants. How has 3D printing changed medicine so far, and what can these bioprinters do for us in the future?

Current Applications for 3D Printing in Medicine

3D printing, while increasingly commonly used for making prototype models or building architectural replicas, has practical use in the medical field as well. How is 3D printing already being used? Some frequently seen applications include:

- Prosthetic limbs: Traditionally manufactured prosthetic limbs are expensive, which makes them difficult or impossible to obtain for low-income families or for individuals in developing countries. This is aggravated by rapidly growing children, whose limb sizes change every year, increasing expense. 3D printers can make high-quality limbs for a fraction of the cost.

- Custom implants: A replacement hip joint shouldn’t be one-size-fits-all, and with 3D printing, it doesn’t have to be. 3D printing enables doctors to create customized implantable items like hip joints, cranial plates and more that are made to perfectly fit each individual patient.

- 3D imaging for dentistry: It’s not all about printing. The same technology allows for the use of 3D imaging that improves medical care by providing the medical professionals with more accurate scans that can be manipulated and customized as needed. These 3D models, once created, can also be used to create fully customized orthodontic appliances, implants and other items, using 3D printing technologies.

Today these items are printed in medical grade thermoplastic or metal, but what if we could print them with organic materials?

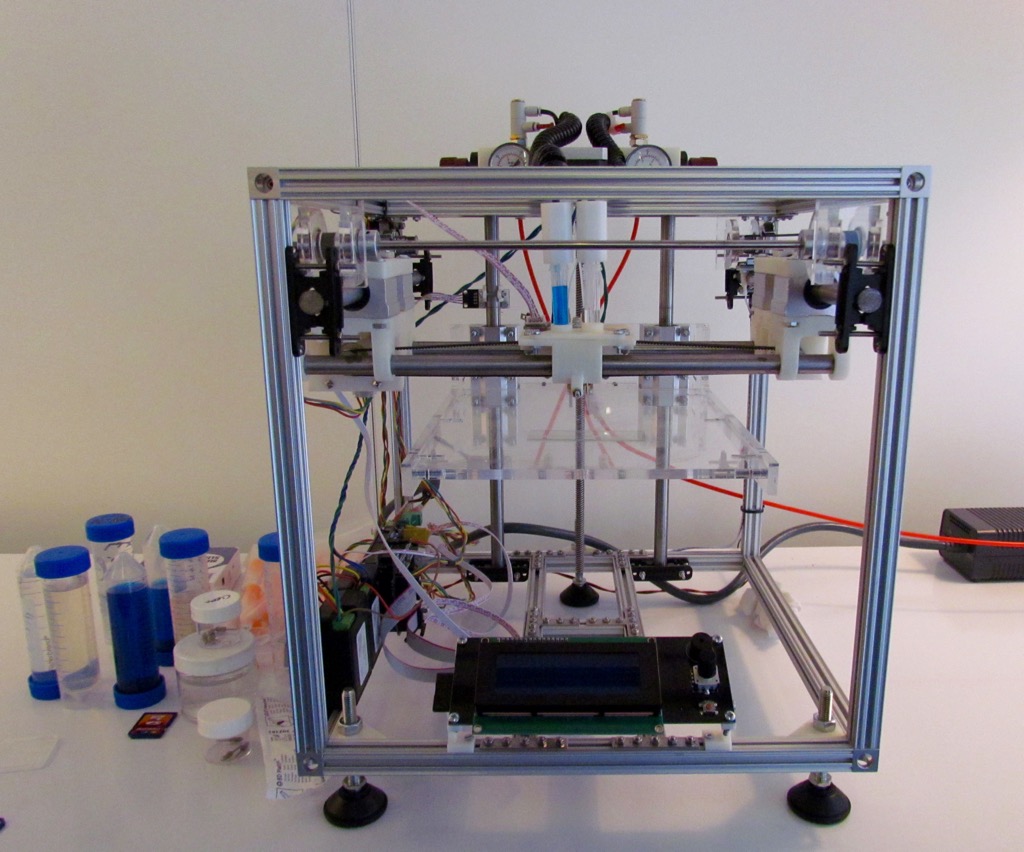

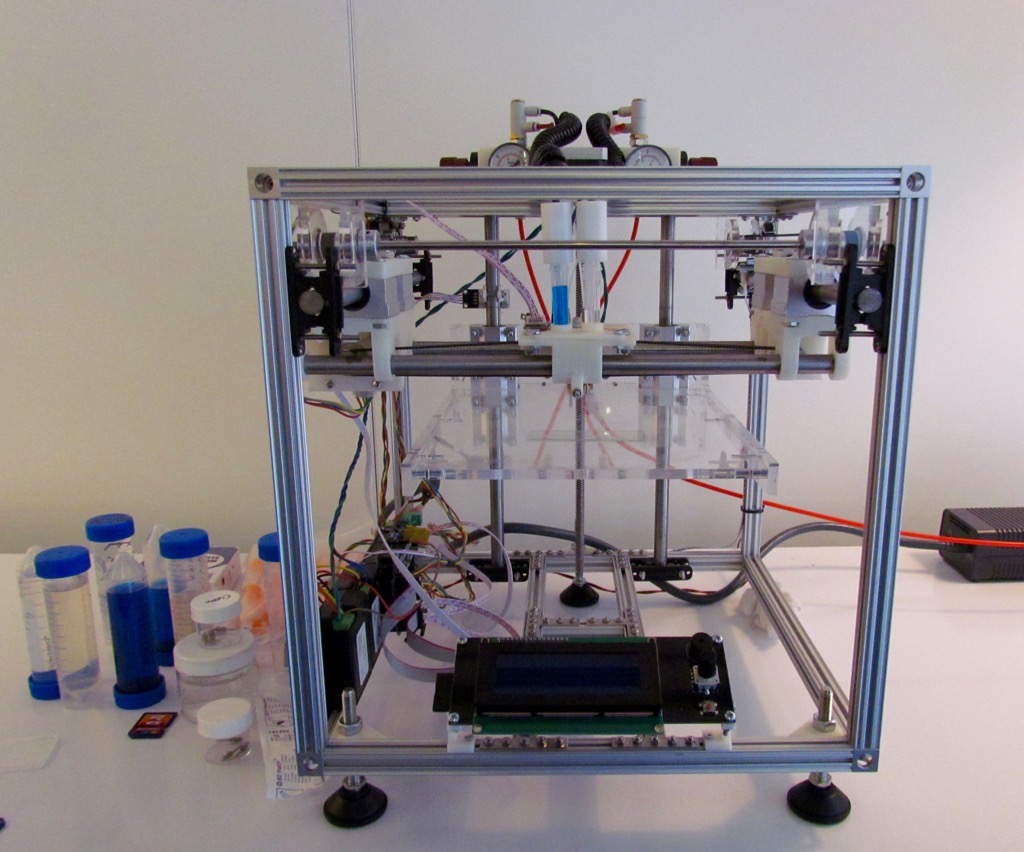

The Introduction of Bioprinters

What is the biggest problem that is faced by transplant patients? Organ rejection. So what if you could create a totally new functioning organ with the patient’s own cells? There would be a greatly diminished risk of rejection and far less need for the cocktail of immunosuppressant drugs that transplant patients have to take for the remainder of their lives.

That is what bioprinting researchers are hoping to do in the near future — and are starting to do now.

One bioprinter, created by Professor James Yoo in North Carolina, is being designed with burn victims in mind. Specifically, the goal is to grow new skin by literally printing it directly onto burned tissue. This has already been proven to be an effective type of treatment. Stem cells from the injured patient, sprayed directly onto the burned tissue, can heal the wounds with minimal scarring. This bioprinter makes it more targeted compared to previous methods, which were far less precise.

Researchers at Cornell University have used a bioprinter to 3D print a heart valve using organic material from a sheep. It will soon be tested in that same sheep, but if it proves to be a viable replacement, it could potentially change the way heart valve replacements are treated. Imagine being able to replace a heart valve with your own tissue rather than a valve made from inanimate plastics. It might be closer than you think!

Many 3D printing experiments have been successful because they are working with cartilaginous body parts — they don’t have many nerves or blood vessels, so they are simpler to print. Harvard University is hoping to change that by using a 3D printer to successfully print blood vessels. While this might not be as useful on its own, it is a huge step toward being able to 3D-print organs that require a blood supply.

Being able to print organs using the patient’s own cells will turn the field of transplant medicine on its 3D-printed ear — since Cornell’s been 3D-printing those, too. Once these printers are approved, patients won’t be left languishing while they wait for a compatible organ donor. Instead, their doctors will be able to order a new organ printed for them, ready to be transplanted as soon as the print cycle finishes.

3D printing has the potential to save and change lives all over the world. We can’t wait to see what they do with it next.