VSHAPER offers a type of 3D printer almost no one else produces: a custom machine.

The Polish company produces a rather extensive line of extrusion-based 3D printers, including the following models:

VSHAPER Go: A reasonably sized desktop 3D printer whose enclosed build chamber and automated leveling can easily print PLA materials only. Build volume is 215 x 215 x 200mm.

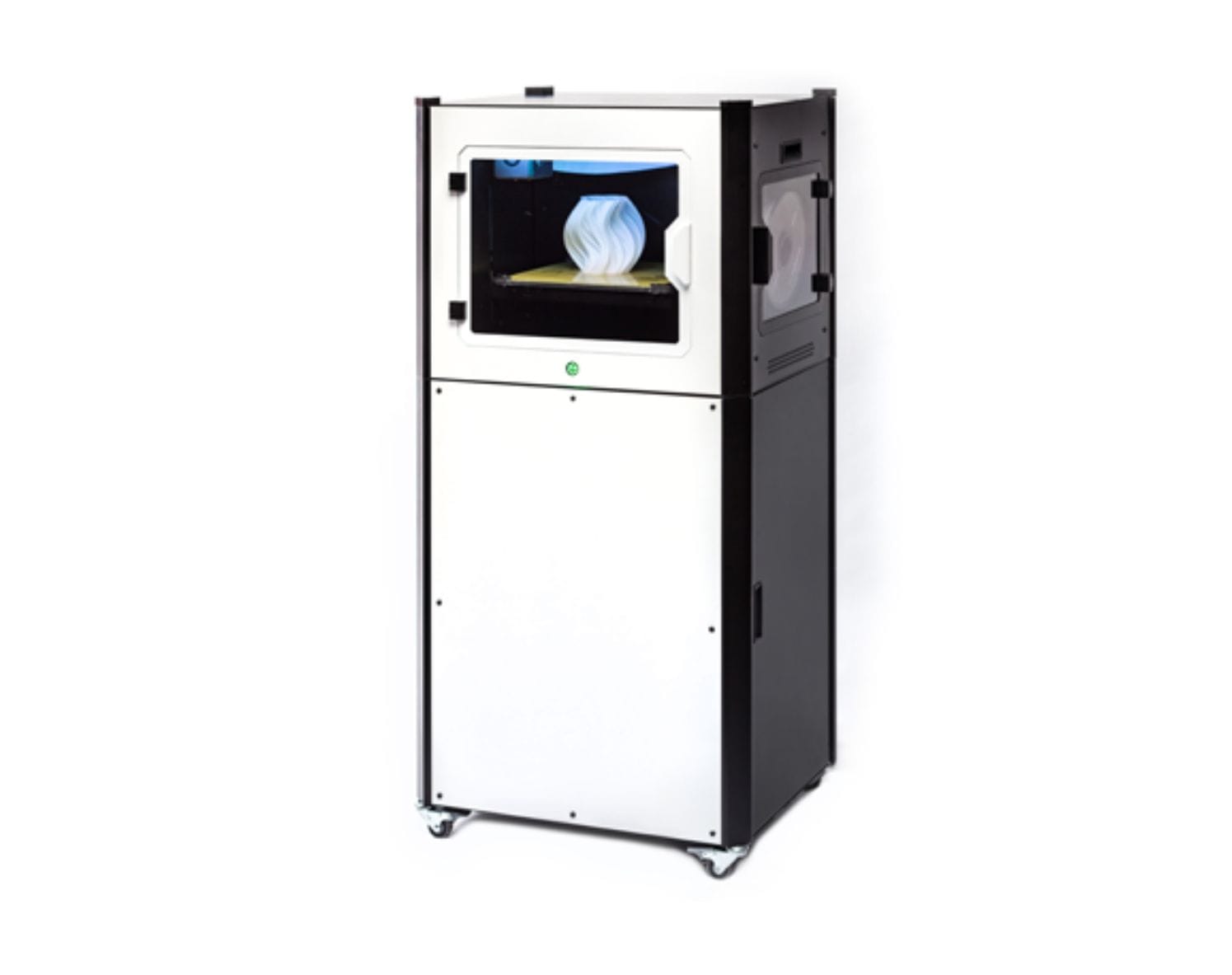

VSHAPER 270: A larger unit that is equipped with its own stand. The 270 model is also enclosed and is capable of 3D printing PLA, ABS, PMMA, PA, PET-G, HIPS, PVA and PC materials. To complement these unusual materials, the 270 also includes a carbon filter to remove some of the odors generated by them. Unlike the “Go” model, this one includes a heated print surface, essential for handling the more exotic materials. The 270 can also be obtained with a dual extrusion setup, enabling the use of dissolvable support structures (PVA).

VSHAPER 450: The 450 has a much larger build volume, surprisingly 450 x 450 x 450mm, but does not have the capability of 3D printing in all the same materials as the 270. In fact, the 450 appears to be designed to 3D print in ABS, but with a second nozzle using HIPS as a support material – and note that HIPS is dissolvable in lemonine. The 450 can also accommodate different nozzle sizes, up to 1.2mm in diameter, for more rapid 3D printing.

VSHAPER PRO: The PRO, which has a moderate build volume, has a much higher maximum extrusion temperature of 450C, enabling the use of much more exotic materials like PEEK. This model includes an onboard UPS as well.

VSHAPER MED: Unlike the other models, the MED is a resin-based machine that is designed for medical use. It is capable of 3D printing high resolution objects in medical-grade resins.

And then there’s something called the “VSHAPER CUSTOM”. Here is the description:

The end-user takes an active part throughout the entire process of defining demands. It is up to him to decide on: the size of the working area, the number and type of nozzles as well as the features of the platform used in the printing process.

There’s a wide range of features to choose from: automatic platform calibration, ventilation with carbon filter and a camera that makes it easier to monitor the printing process. The device can also be equipped with emergency power supply.

This is quite interesting: the company will custom build the entire machine to your specifications. While a few other companies might offer to build a “stretch” machine with different dimensions, VSHAPER’s offer seems more comprehensive.

Pricing, obviously, “depends”.

Via VSHAPER