We’re looking at a very interesting air safety system for desktop 3D printing today.

Protopro, a small UK-based company is marketing a device that can attach to 3D printers and purify the air, removing a number of particles and toxic fumes that most 3D printer operators seem to ignore.

We’ve written extensively on these emissions for years now, as we constantly see new desktop 3D printers – and even some commercial / industrial units – be marketed with absolutely no regard for air safety.

It turns out that as plastic is heated, it tends to emit gases and ultra-fine particles that infest the nearby atmosphere. While the best solution is to have an air ventilation system that moves all affected air outside, replacing with fresh air, this is not always possible due to the constraints of many offices and workshops.

In such situations, there are two approaches: first, you could acquire a 3D printer that includes some kind of filtration system. A second solution is to acquire an accessory unit that attempts to capture the emissions in a standalone box. That’s what Protopro is attempting to do.

Most of the on-board 3D printer air filtration systems include a HEPA filter, which we discovered would not actually remove the ultra fine particles: it turns out 3D printer emissions include particles smaller than the capture size of standard HEPA filters.

So we’re now a bit suspicious of on-board filtrations systems.

But how does Protopro do it? They have a rather simple, but well designed approach to the problem, using a two-phase filter approach.

The first filter captures larger particles, such as you’d see with a HEPA approach. This is good, but not the complete solution on its own. Secondly, they have an additional filter that uses an electrostatic approach to capture gases and toxic materials, including the ultra fine particles.

This secondary filter is sourced from Moldex, German manufacturers of effective and economical respirator filters. Yes, these would be the same filters you’d find in a respirator used in, say, a paint booth, and are more powerful than standard HEPA units.

These filters are attached to fans and a ducting system that recirculates air through the 3D printer’s build chamber. Protopro claims that the device is 99.995% effective.

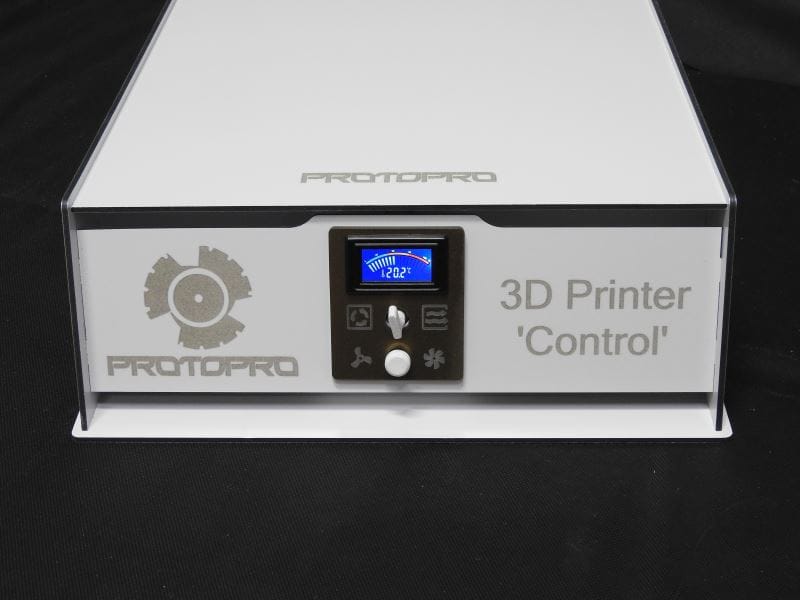

Their “3D Printer Control” unit also includes a digital readout of current build chamber air temperature, for interest.

One problem with their approach is that it’s intended to sit on top of the 3D printer and use vent holes in its bottom side to route air. But many 3D printers requiring this solution do not have an enclosed case, let alone a flat top. This means to use this solution you almost always will have to construct or buy some type of enclosure for your desktop 3D printer in addition to the filter itself.

The good news is that Protopro sells cases for a couple of popular models, but there are many more that you will have to find elsewhere, or design and build your own.

Protopro explains that if you print regularly, you should change the secondary filter each month, which you can obtain from Moldex. The primary filter requires changing every six months. This is not unreasonable for a filtration system, but does require an ongoing expense, rather than an exterior ventilation system that does not.

You’re probably wondering what the cost of Protopro’s solution is, and so are we. We are unable to find the price of the unit on their website, but expect it to be a reasonable cost as it is not a complex product and uses off the shelf components. I’m hoping it’s less expensive than some of the very expensive lab-focused fume extraction systems that are often the alternative product in these situations.

Via Protopro