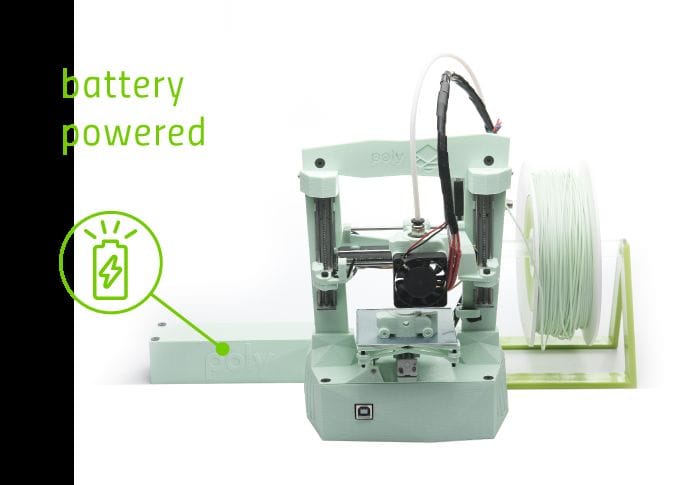

A very low cost – and truly portable – desktop 3D printer has launched.

The “Poly” is the product of 3D Rap, an Italian 3D printer startup that has produced several different (and much larger) desktop 3D printers in the past, several based on open source RepRap designs. The new Poly machine, however, is a bit different.

It’s a small machine, as one would expect for a portable device, having a build volume of only 60 x 60 x 60mm, perhaps the smallest build volume I’ve ever seen on a non-resin 3D printer. It even weighs less than 1 kg.

The print surface is not heated, and thus you can really only attempt to print PLA materials with the Poly.

Poly – Bio and Easy 3D Printer

To me the most interesting feature of the Poly is that it can be battery operated. The not-included battery is actually a case into which you would install your own standard batteries. It appears to be a case requiring a small collection of standard D-cells. It’s not clear how long the device would operate given a fresh set of batteries, but it wouldn’t have to be very long due to the small build volume of the Poly.

The battery capability means the device is literally portable. You can set it anywhere, although it is not entirely clear to me why you would want to do so. Perhaps you could bring it along on an expedition to print spare parts?

But there is another surprise with the Poly: it’s a multi-tool machine. You can swap out the 3D print toolhead for two other toolheads.

One is a laser system with which you can engrave small objects. The wattage will be low, so don’t count on cutting anything, but you can likely burn patterns into wood or paper, albeit slowly. Safety glasses are included with this option.

There is also a paste-extrusion toolhead, strangely named the “Poly Ciok”, which can be used to extrude pasty materials like cookie dough, chocolate or peanut butter.

Finally, the Poly can also be used as a drawing machine, in which a marker pen can be held by the toolhead and 2D sketches produced.

The toolheads are magnetically attached, making it quite straightforward to swap them.

3D Rap makes a big deal of the machine being made from recyclable materials, in this case PHA thermoplastic. However, it’s a small machine whose recycling capability will be of limited affect, so the point is mostly symbolic.

What is more interesting is the price, with the basic Poly being made available at only €254 (USD$300), although this includes only the 3D printing capability and not the laser or paste extruder.

Those you can get in a slightly higher-priced bundle at €559 (USD$665). So for under USD$700, you can get a multi-tool making device!

Who is this machine best for? The build volume is likely too small for serious professional use, as is the lack of an ability to 3D print in proper engineering materials. However, I suspect the best application for the Poly would be in schoolrooms as a means of introducing students to the concept of making and digital manufacturing.

The portable aspect would enable the machine to be easily moved around the school room for educational flexibility, and the lack of engineering materials is no barrier to students learning how to make things of their own design.

One key aspect of considering an inexpensive 3D printer from a startup on Kickstarter is the viability of the project. Many 3D printer startups have failed miserably, primarily from mismanagement of manufacturing execution, occasionally leaving backers at a loss.

Is that the case here with 3D Rap? While we’d advise everyone to review our launch checklist, in this case there are some good signs: 3D Rap is an established company with several existing products and have partnerships with multiple relevant companies, making the likelihood of this project being successful is increased.

Via Kickstarter and 3D Rap