Researchers at the University of Michigan have apparently developed an algorithm to speed up 3D printing operations.

The key to their new method is in the vibrations produced during 3D printing. As most 3D printer operators know, the motion systems on 3D printers can shake quite significantly as the tool head moves swiftly to and fro over the print surface.

If one were to attempt to speed up the printing process by simply cranking up the base print speed, the result is likely a failure. It’s possible the speedy tool head, if moving back and forth as sometimes is required, would cause vibrations that could corrupt the print.

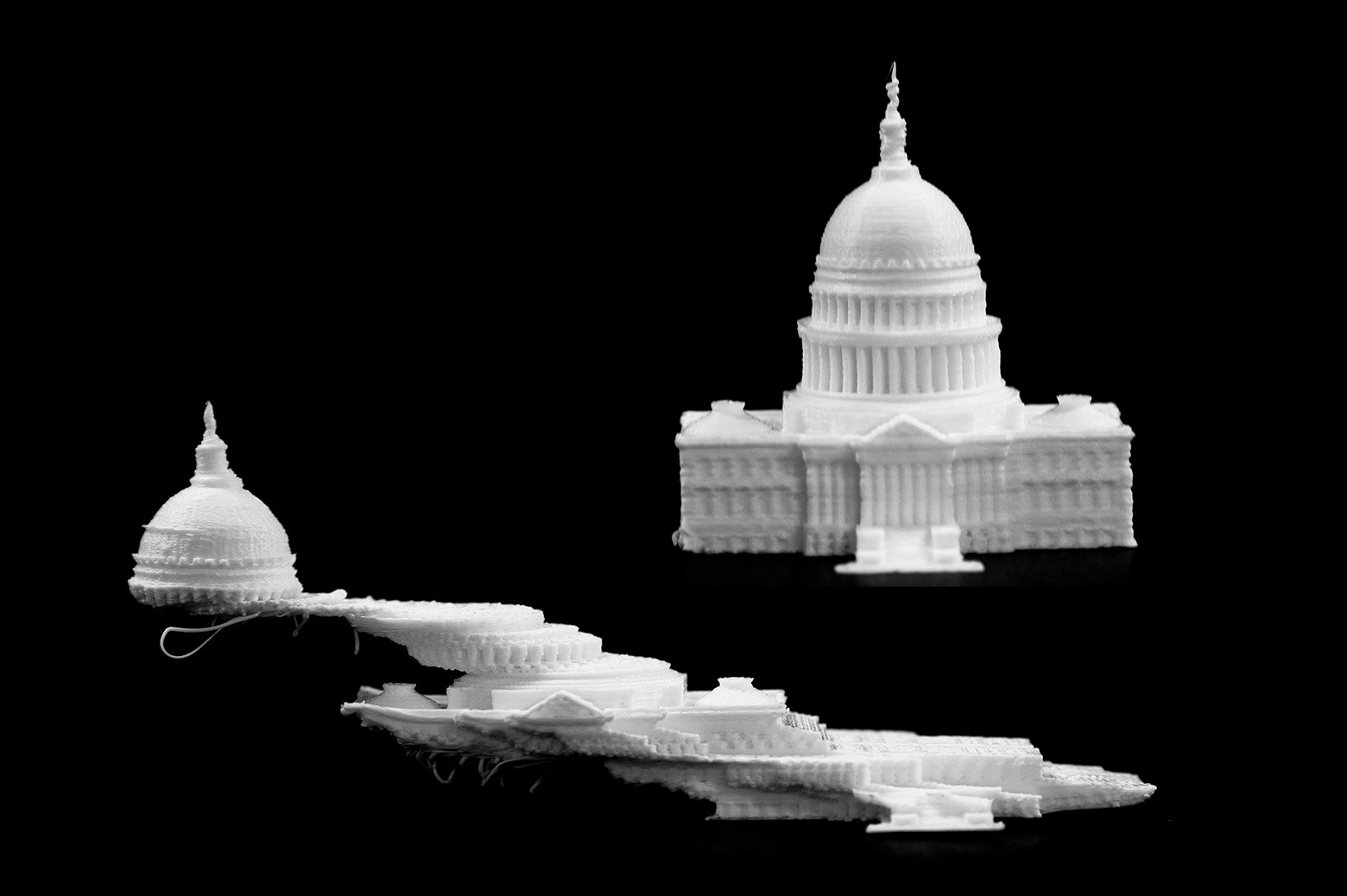

In another case, as this image shows, the rapid movements could cause the axes to shift, making all subsequent printing take place in the wrong locations. While this effect can happen on slow machines if, say, the belts were not properly tensioned, it can happen far easier if the tool head is ripping along at warp speed.

That is what the University of Michigan’s algorithm is all about.

It seems that the algorithm will examine the tool path to determine periods where excessive motion will take place, and the speeds are adjusted to moderate the effects of the motion.

From the description, it appears they are allowing speed when it is feasible, and not when it is infeasible. This makes much sense.

I’m reminded of other 3D printing speedup approaches, one being Create It Real’s powerful controller board, which enables higher speeds by being able to compute the required movements at a more rapid speed. The new algorithm could potentially be complementary to Create It Real’s processor.

There is no word on when this approach might hit the product shelves. But if it proves commercially feasible, you can bet it eventually will.