Some time ago we had a test of several of Fiberlogy’s speciality 3D printer filaments, and we’d like to update that report.

While we were quite impressed with the four materials provided, we did have some difficulty 3D printing two of them: the flexible Fiberflex 40D and the wood-infused Fiberwood materials. The two other materials, HD PLA and PLA Mineral, both provided fantastic and unique results. I’m particularly impressed with the mineral filament, as it seems to print objects brilliantly, as if they were white stone.

However, we did manage to print several items with the Fiberwood and Fiberflex 40D, but when Fiberlogy saw our results they felt we could have done better. They contacted us directly to make some suggestions on how to best 3D print these particular materials.

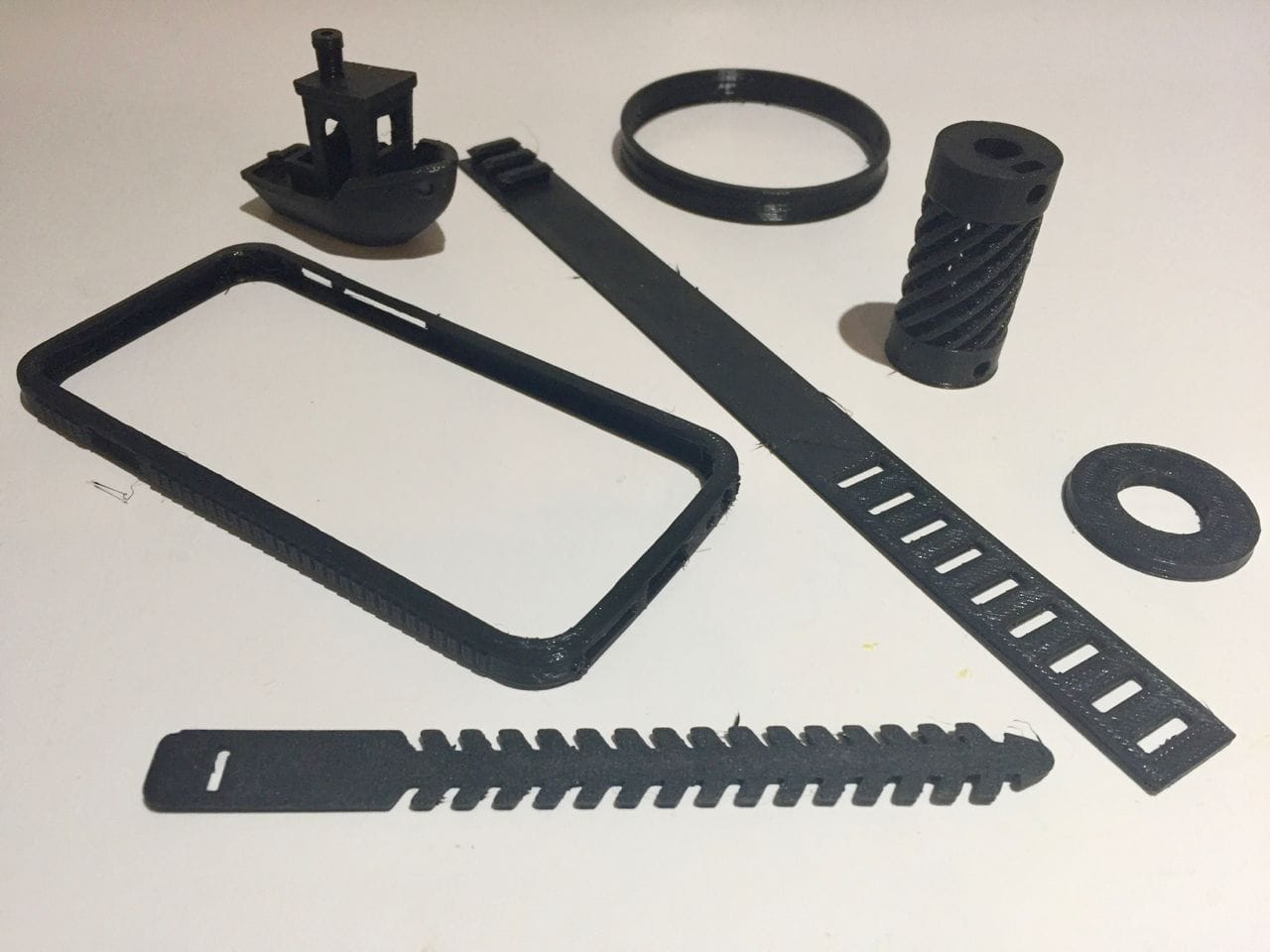

First we attempted to re-print several objects with the flexible Fiberflex 40D. Of course, we used Fiberlogy’s suggestions for print settings.

The results were significantly better than our previous attempts, and we were able to print a wide variety of objects using this material. Here you can see some if the items we produced with the black colored material.

The new settings enabled us to easily 3D print far more complex objects in this highly useful material. One item, an iPhone case, worked so well it became our “production” case for a while.

What’s fascinating about this material is that it is quite functional; you can produce an object that can be used. That is to say, an object that flexes while in use. Items like a phone case are ideal with this stuff.

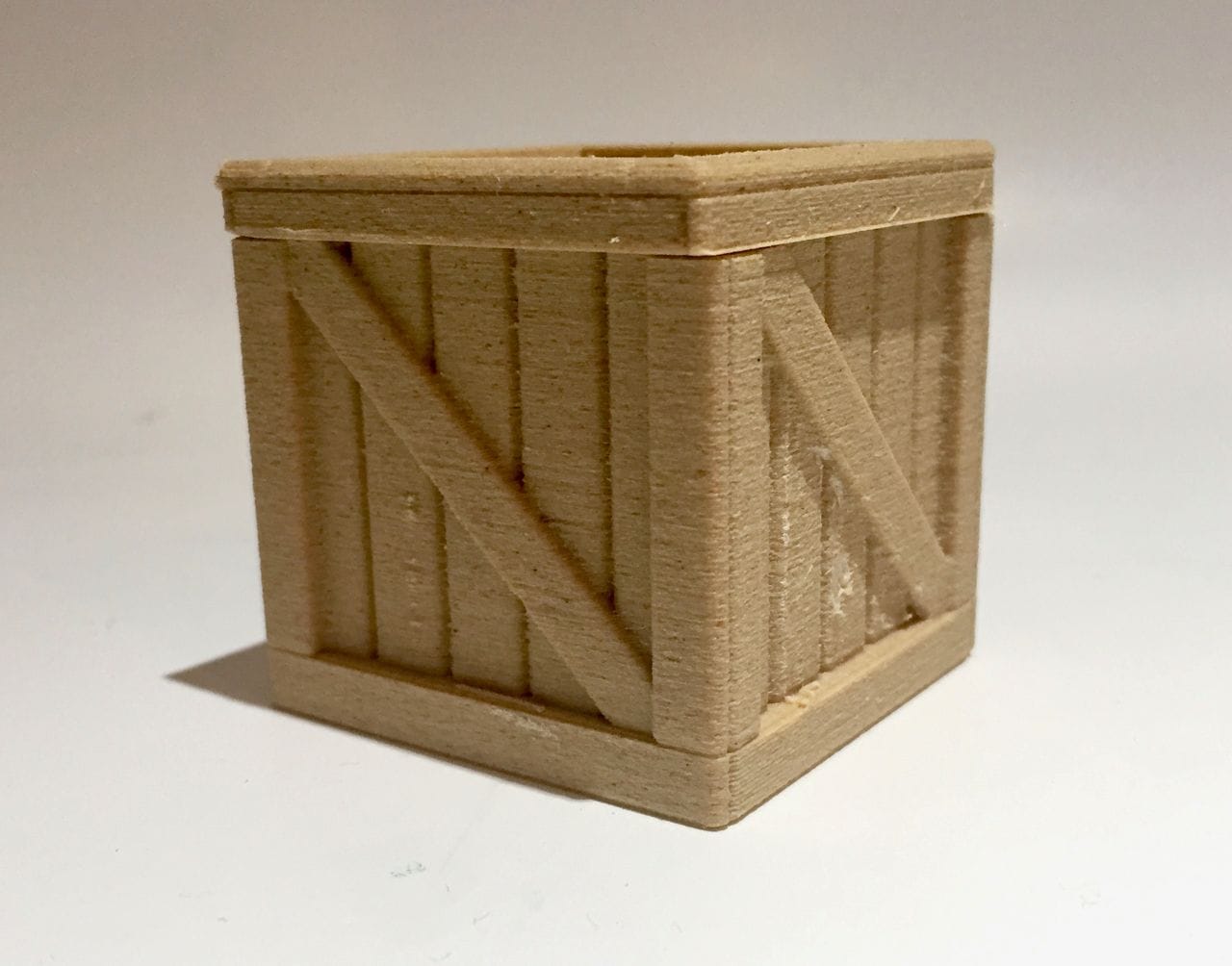

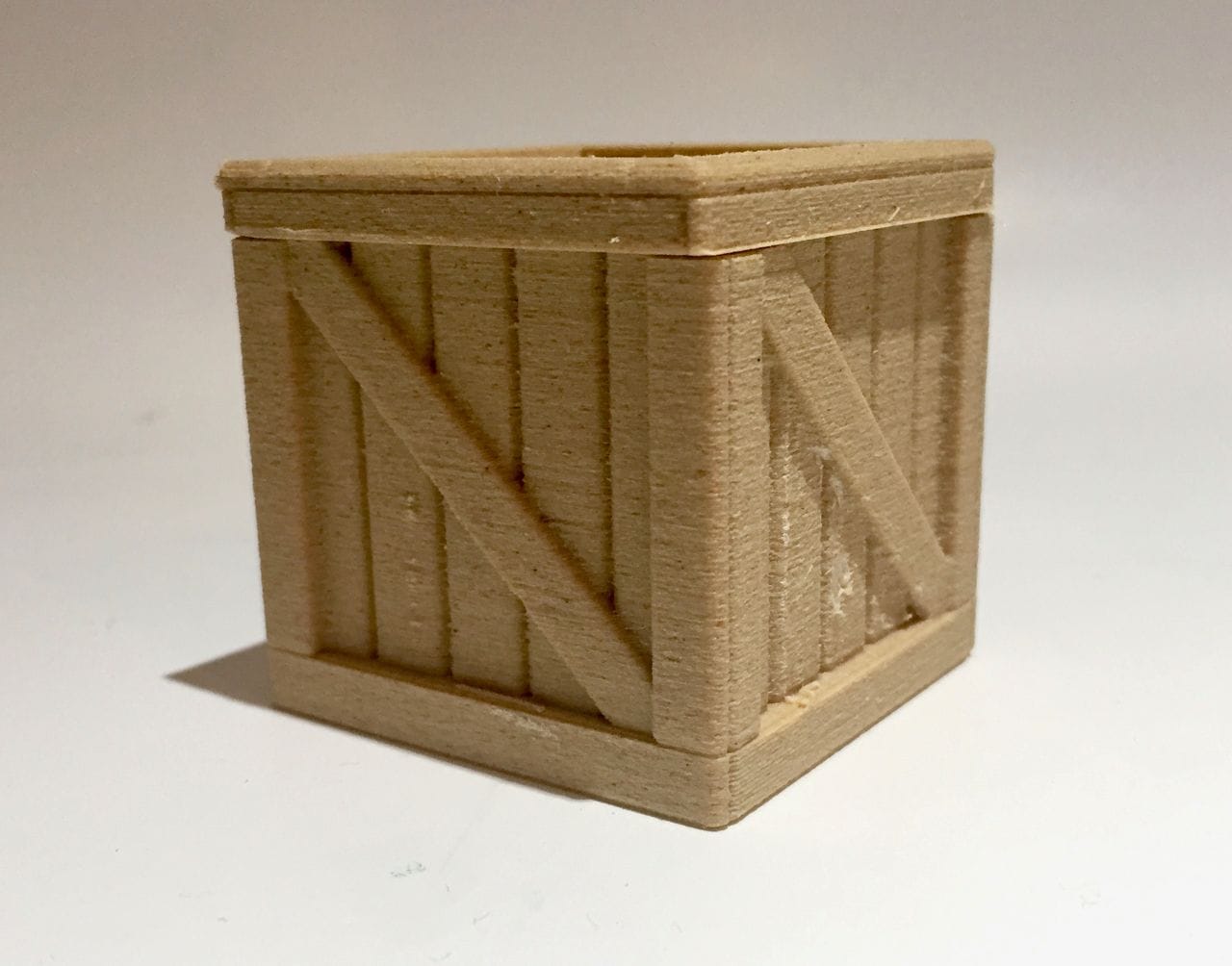

The second material we had some challenges with was Fiberlogy’s Fiberwood material. This is essentially PLA infused with enough wood particles for the print to take on many of the characteristics of an actual wood object.

Fiberlogy recommended we use a 0.5mm nozzle, instead of our standard 0.4mm nozzle, insisting that the prints would be of better quality. We can’t argue with the manufacturer here, so we procured a 0.5mm nozzle and gave it a try, again with the settings as recommended by Fiberlogy.

Lo and behold the prints worked extraordinarily well after a bit of dialing in the settings. It seems that this material is somewhat more sensitive to slight temperature differences than other filaments. But that’s ok – as long as you get the temperature set correctly, you will obtain good print results.

The Fiberwood material, when printed, produces a very wood-like surface. Of course, the objects printed seem a bit light for “wood”, as the interior of the objects is sparse as compared to real wood, which is 100% solid. The wood objects can also be sanded, painted and drilled, just like real wood.

But what’s even more interesting about this episode is that there is a lesson about 3D printer filament: you MUST use the correct print settings, or you may not get good results.

I’m reminded of many times having trouble 3D printing with various filaments, and I’m wondering how many of those bad experiences were simply due to incorrect print settings. You may have had the same experience. I suspect that any filament can be made to work properly, so long as it is chemically consistent and has a diameter that doesn’t vary significantly.

The moral of the story here is that you really should pay attention to the filament manufacturer’s advice on usage. They know how to print with it, perhaps better than you do. I’d recommend using the manufacturer’s advice as a starting point, from which you can fine tune to best fit your equipment.

Via Fiberlogy