Authentise has announced a deal with SLM Solutions to integrate real time data.

Let’s catch up a bit here first.

SLM Solutions produces powerful 3D metal printers that are used worldwide to manufacture industry-certifiable metal parts. And I’d like to emphasize that word “certifiable”. The big money these days with 3D metal printing is for parts used in particular industries. Industries like aerospace and medical, where parts almost always must pass through certification processes or they cannot be used. You wouldn’t want your aircraft to fall apart while in flight, would you?

It is thus of utmost importance to ensure the parts are produced accurately on each and every print job. If not, you must re-run the job, which can be extraordinarily expensive, as the materials cost up to USD$500/kg, let alone the cost of operating the machine and its post processing gear.

Imagine a scenario where you are 3D printing an expensive metal part – and in fact all 3D printed metal parts are expensive – and it’s going to fail. You’d want to know RIGHT AWAY when it fails so that you can stop the print and avoid wasting expensive materials and time by restarting the job.

This is part of what SLM Solutions has been working on lately, as they’ve included, for example, a real-time laser quality monitoring system. This system could detect flaws in the print during operation.

OK, now let’s talk about Authentise. They’re a service provider that produces a middleware environment, 3Diax, for 3D printing. In their system you can route 3D print jobs between workstations to machines, with appropriate tracking, monitoring and controls.

Their new announcement is this, from SLM’s Henner Schöneborn:

We’re very pleased with this partnership with Authentise, as it represents an expansion of our existing Industry 4.0 initiatives and solutions. This collaboration enables our customers to access real-time production data from SLM machines – a capability that’s enormously important especially for customers that deploy our machines for series manufacturing of components. With this partnership, we’re taking an important step towards the fully automated processing of orders on our machines. Authentise supplements our Additive Hub design software that we developed in-house.

And Authentise’s CEO Andre Wegner added:

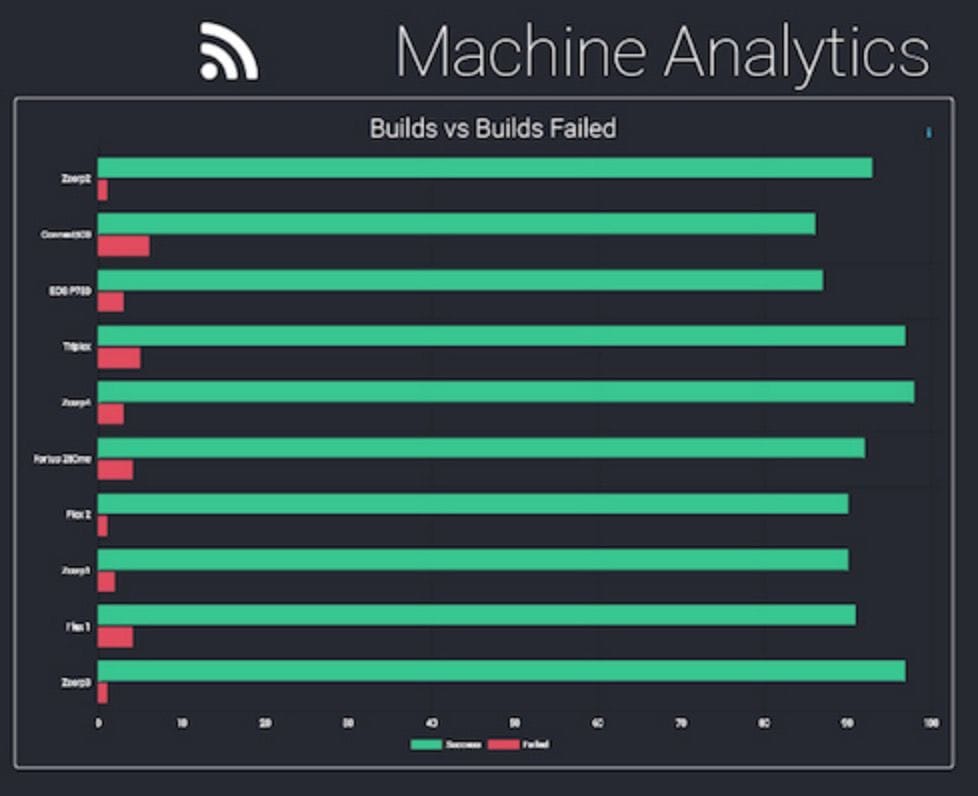

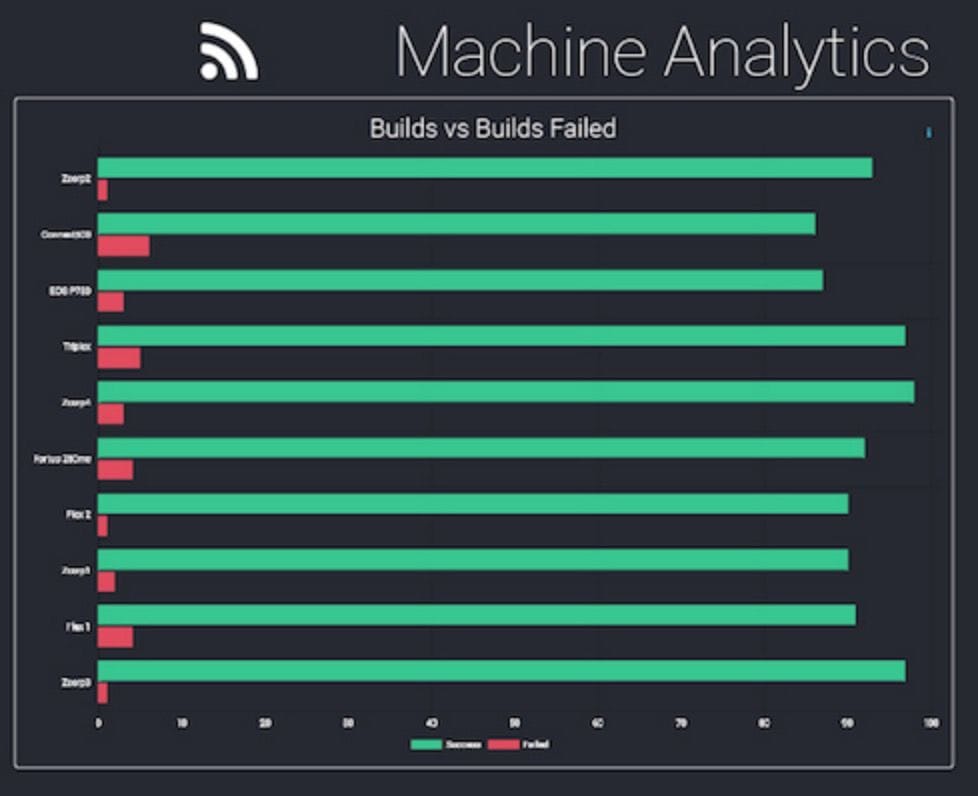

The direct data access to SLM machines that has now been enabled can be combined with other functionalities of our 3Diax software modules to automate manual tasks. It is possible, for example, to automatically update an order status, or generate documentation that enables finished components to be traced back to source. Our 3Diax platform utilizes data in the sense of a self-learning system. The partnership also makes it easier to integrate SLM machines into SLM Solutions’ customers’ IT systems, and facilitates the transparent analysis of production data through the 3Diax Machine Analytics module.

To me this is a big deal because the integration of hardware directly into the middleware network makes so many more workflow options possible. One of them will no doubt be the ability to monitor jobs to detect failures much earlier.

It’s another step towards the deeper integration of 3D printing technologies into production environments.

Via Authentise