I had the opportunity to give MakerBot’s new Tough PLA system a try, and was impressed.

MakerBot has been transforming their business for a couple of years now, and I wondered how their announcement of “Tough PLA” fit into those plans. After some testing, it became clear.

But first, what is this “Tough PLA”?

It is simply another PLA-style 3D printer filament that has a bit more flex to it. Normal PLA can be quite brittle, and thus if you’re making parts that have any portions that must slightly flex in operation, you’re risking a crack and failure.

I’m certain that if you operate a 3D printer you’ve encountered the situation where you’ve made two parts that are supposed to fit together, but due to very slight differences in size during printing do not actually fit together. Nuts and bolts, caps and bottles, it’s all too frequent. You end up going back to the drawing board by slightly increasing (or decreasing) the size of one component and re-printing. Takes longer, frustrating, etc.

The Tough PLA overcomes that by introducing some “give” to the material, making it a lot easier to make parts that fit together. When you print parts that fit together, they will actually stretch very slightly. They almost always fit!

But the MakerBot system requires more than just the filament. You’ll need one of their recent 3D printer models, the ones with the Smart Extruder system. Why? Because in order to 3D print Tough PLA you will have to use a different extruder, one designed specifically for Tough PLA.

I’m not sure what the differences between a standard PLA Smart Extruder+ and a Tough PLA Smart Extruder+ might be internally, but I suspect the mechanical design varies to account for the slightly flexible Tough PLA filament. Perhaps it gets bogged down in the standard extruder, like one often sees with flexible filament.

By the way, you might be wondering exactly how flexible this stuff is. Here’s your answer:

The filament is extremely bendy, so much that you can actually tie it in a knot without issue. However, it’s not limp, either, like many flexible filaments can be. Tough PLA is somewhere in-between.

There are no unusual settings to select with this system, as the MakerBot software “knows” what to do with Tough PLA. Just install the extruder and load the filament, and their slicer will prepare the job appropriately.

I found the Tough PLA to be quite reliable when printing. In fact, after printing a few dozen items I had literally no failures. Of course, if you print more you might run into issues, especially if you’re attempting to 3D print pathological 3D models.

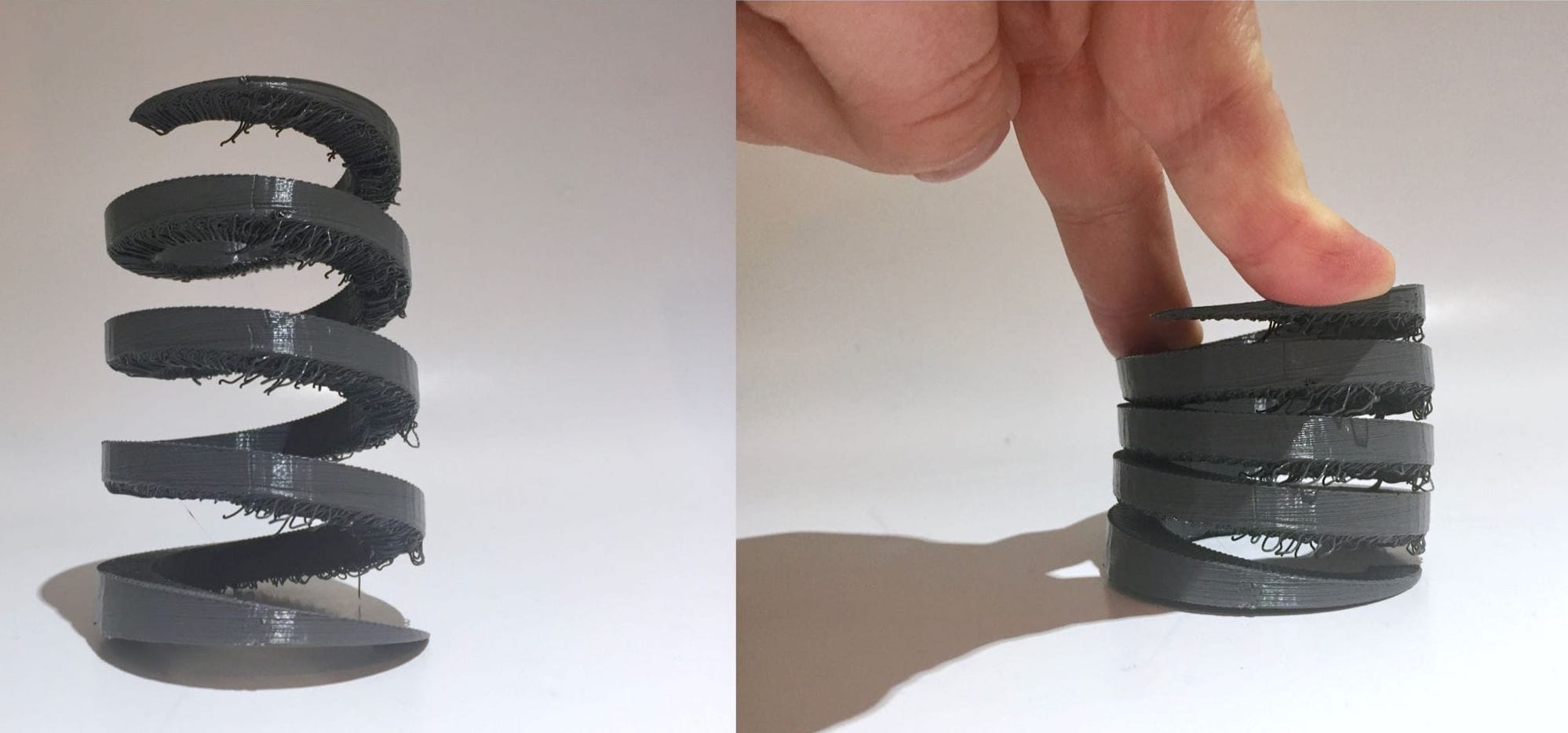

The novelty, of course, is the flexible properties of this material. Accordingly, I 3D printed a number of “flexy” objects, like this compressible spring to satisfy my curiously. All worked very well.

Note, however, that the spring has quite a bit of drippy extrusions on the underside. I have to point out that this was printed WITHOUT SUPPORT and it still came out very well. I left the strands visible to show you how easy it was to 3D print objects even at extreme angles. And for purposes of the spring, the excess material really didn’t matter anyway.

But after getting my fill of bendable items, I left the Tough PLA extruder and spool on the machine. And as you know, MakerBot’s new 3D printing system is cloud-based, meaning you can shoot a job over for printing whenever you like from your workstation. I went into this mode for a while.

As it turned out, I was fiddling with a design for a phone mount for the car, and this required a number of iterations. In each instance, I simply sent the 3D model to the Tough PLA setup and let it print. After a while this process became quite routine.

And then I realized what MakerBot is doing here. With this material, combined with the cloud driven printer, you have a setup that can very easily and quickly produce functional prototypes, at least for fit testing. After some use your thought process changes: In your mind there’s this printer that can reliably produce your functional model that’s always ready to go. The reliability of the system and the material allow you to focus on the quick task of getting a rapid prototype done, and you don’t worry about the machine or any fuss getting it going.

Transform this to a business, say a design studio or engineering shop, and now I understand what’s going on here. They are the audience MakerBot is courting with Tough PLA, and it seems to work so far.

Via MakerBot