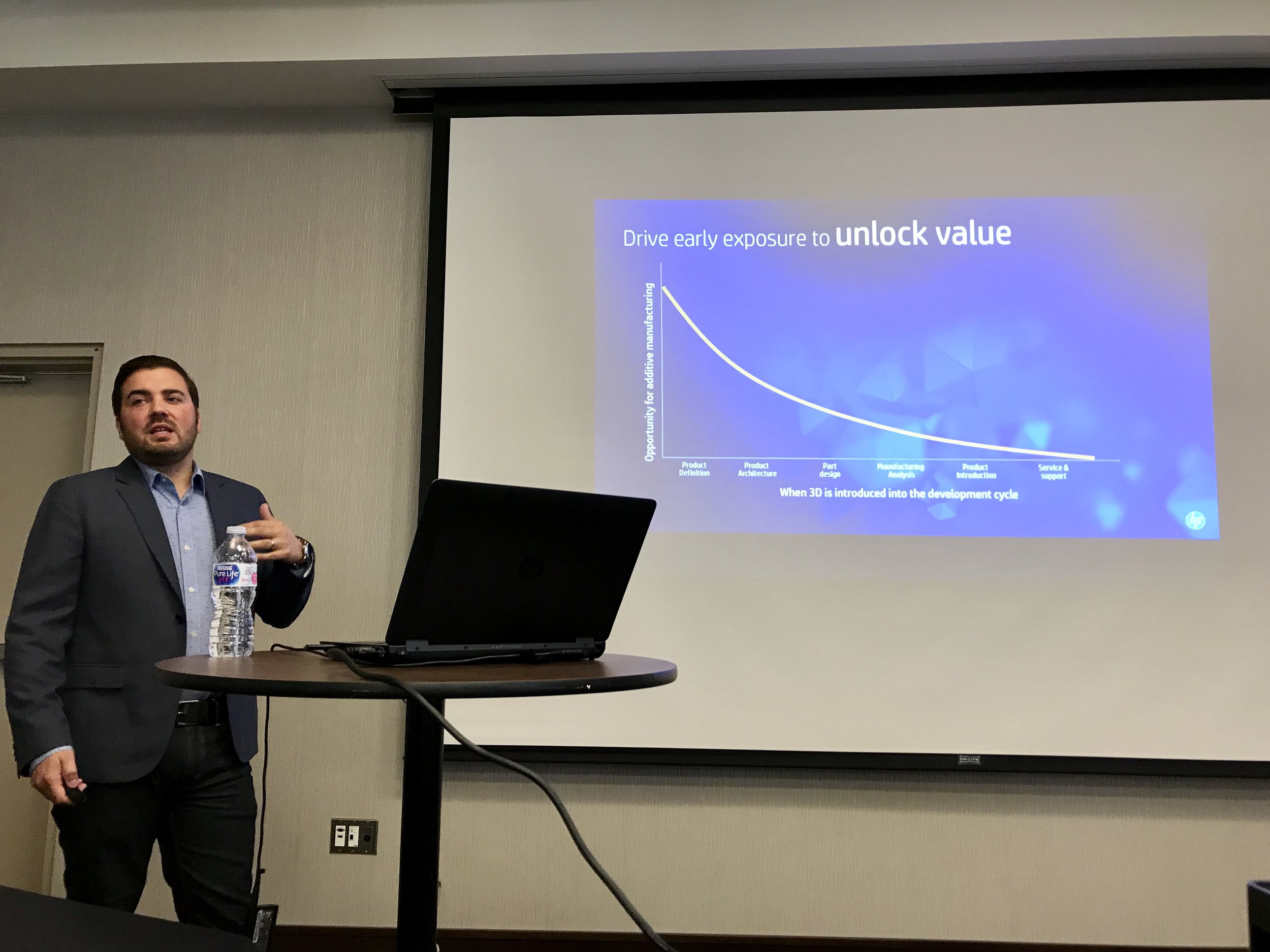

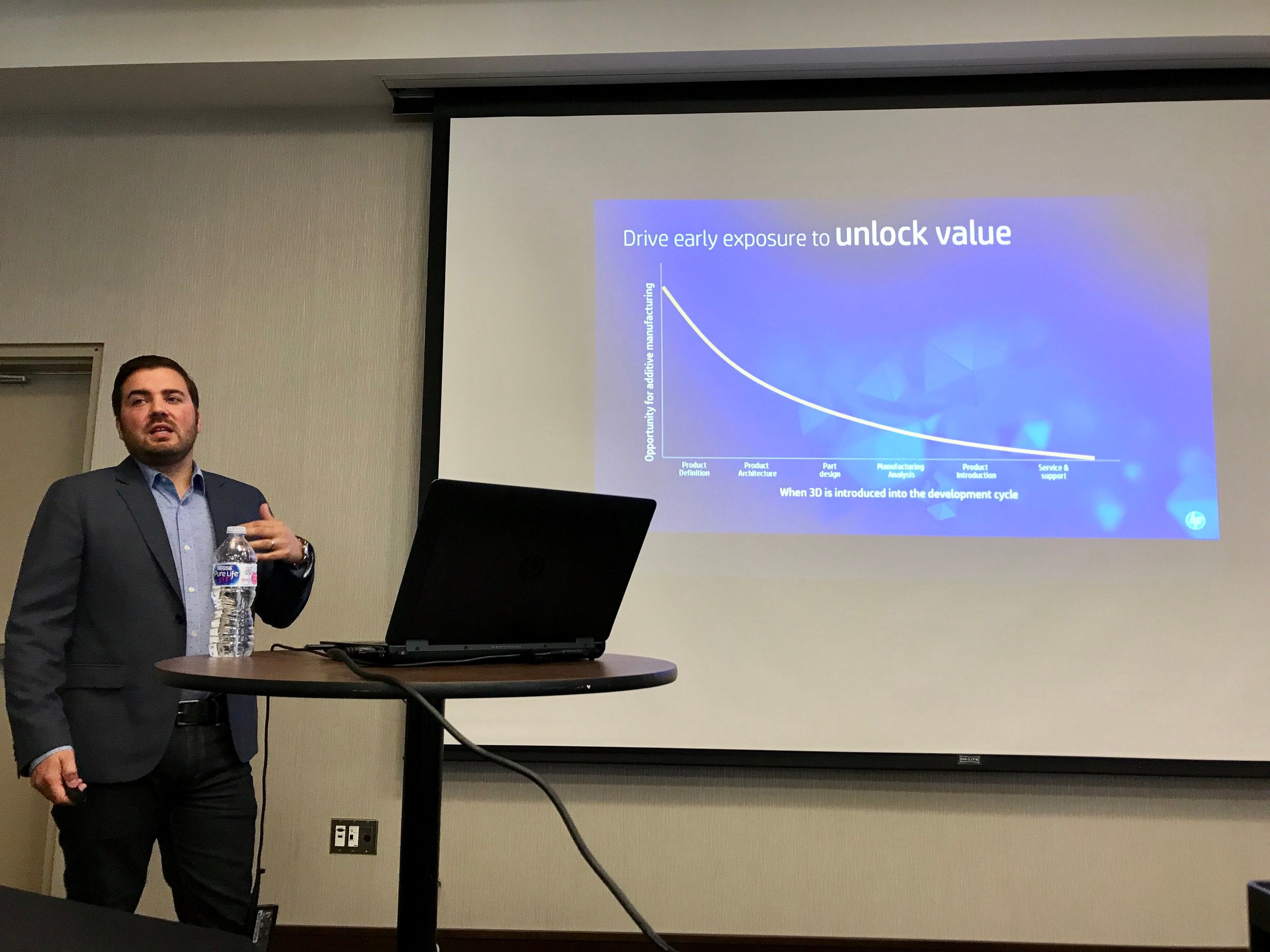

How do we get to tomorrow, to use 3D Printing for true Manufacturing applications through to production?

There are ways to optimize a design for Multi Jet Fusion (MJF) technology.

- Printed layer optimization can be done by eliminating unnecessary material and therefore reducing the cost per part.

- Packing density optimization

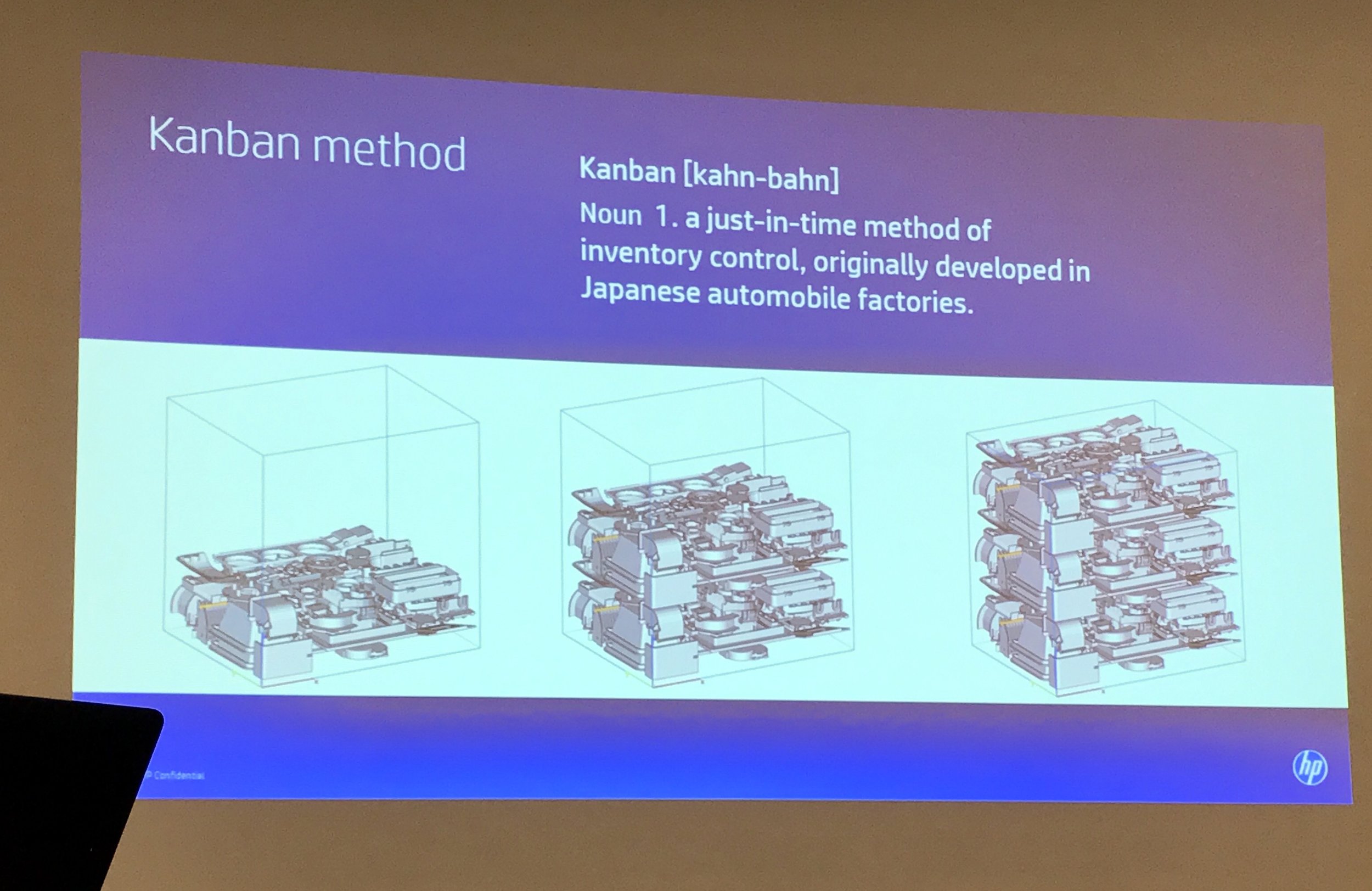

Integrating the Kanban method and DfAM (Design for AM) optimizations with the use of Auto-packing software resulting in more dense parts.

- More layers of parts = cost per part is less

- Utilization of capital

- Increases productivity

- Decreased cost

Design recommendations:

- Identify the build direction

- Avoid sudden changes in Printed surface area

- Think about packing density. More parts together = less cost

Designing parts (during the design phase) for packing density in order to push manufacturing optimization resulting in reduced costs. This is a different way of thinking about designing parts. Also abstraction / foldable designs. The design can be advanced through communication with SAP (collaboration room) and Siemens – auto-packing software.

Read more about efficiency of 3D Printing.