3D Systems, whose stock price recently took a tumble, came back with a series of very interesting 3D printing announcements.

Let’s take a look at all the announcements together and then see what this means.

The first announcement dealt with their long-awaited Figure 4 system, which has been slowly described over the past two years in increasing detail. However, each time we saw the device (or its prototypes) it was unclear when this concept would become an actual product you could purchase. Now that day has arrived, as the Figure 4 is now officially available.

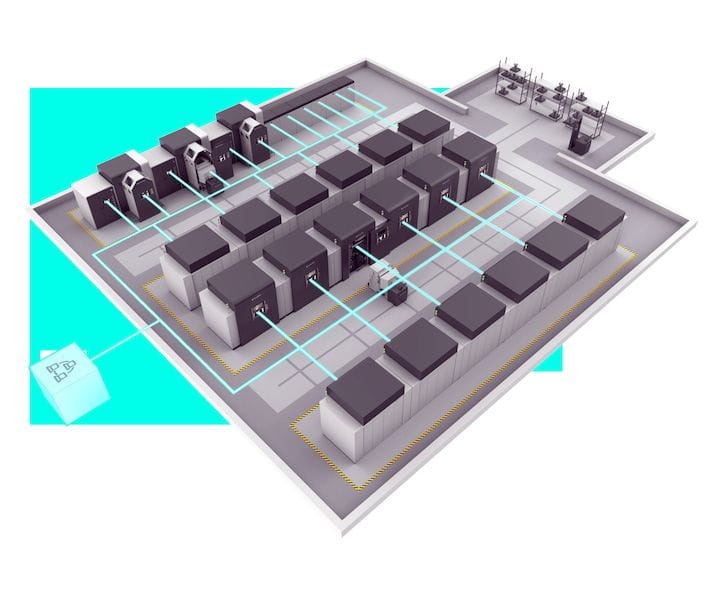

The Figure 4 is a modular system that essentially robotizes their SLA technology; a robotic system moves parts from one station to another, implementing a more-or-less complete manufacturing system (see image at top). And it does work; at one trade show we observed the 3D Systems booth being buried under a huge pile of parts that had been continuously printed with the system.

There are four different models of the Figure 4:

- A Production unit offering full customizability to match a manufacturer’s needs

- A Modular unit that provides a way to mix and match processing units within the system

- A Standalone unit for low volume production and possibly prototyping

- A Dental unit that includes components designed for dental production

Pricing of the Figure 4 systems is quite variable, starting at USD$25,000 and going up to USD$1M, and is dependent on exactly what model and components are selected.

The different Figure 4 units will be delivered in various dates in Q2 and Q3 2018, six to nine months away.

The second announcement is of the new DMP 8500 Factory Solution. This is a larger 3D metal printing system (500 x 500 x 500mm build volume) that features a more efficient workflow, at least those parts involving the machine itself.

This efficiency seems to be enabled by the development of a removable print module, so that you could potentially begin printing a second batch while the first one is cooling down, for example. In addition, you can prepare a module with raw powder before the print begins for faster startup. And there’s even a system for de-powdering prints after completion. All very good ideas.

The DMP 8500 is set to be released in Q4 2018, more than one year away.

Third announcement: The ProX SLS 6100, a more advanced SLS industrial 3D printer. This powder-based machine provides a larger build volume and also includes a variety of workflow-enhancing features. In concert with the machine announcement, 3D Systems also released three new production-grade nylon materials with special properties.

It is not known when the materials or machine will be released.

Fourth announcement: 3D Systems is setting up a “professional services group” to assist clients with specific problems of implementation and operation when integrating 3D Systems products into a manufacturing system. This is quite interesting, as it shows that 3D Systems is very serious about transforming from prototyping into actual manufacturing.

Fifth announcement: A cloud-based service called “3D Connect”, which will remotely monitor 3D Systems equipment for better (proactive) service operations. It seems this feature will be available only on new and selected current systems, however. But again, this is an important step for a production transformation, as the serviceability of a machine being used for manufacturing is likely more critical than one being used for prototyping.

Finally, 3D Systems also announced the “FabPro”, which appears to be a lower-cost desktop-style SLA unit. This machine appears to be designed for low volume jewelry manufacturing or part prototyping. It’s likely that 3D Systems will offer a wide selection of their materials for use on the FabPro. They say this machine is “Rugged” and “Industrial Strength”, so they expect it to be reliable. Previously they marketed the ProJet 1200, a similar small SLA device, but the FabPro appears to be far more robust. I find this an interesting take on the growing “professional” desktop 3D printer market, which 3D Systems had effectively abandoned when they dropped their CubePro device earlier.

The FabPro is “coming soon”.

This flurry of announcements is quite unusual, although not unprecedented for 3D Systems. There is a bit of a pattern, however, in that many of the machines and services are not available for considerable time periods.

It’s also a bit curious that the company is announcing all this stuff a week before the FormNext show in Frankfurt, which is now the world’s largest 3D print tradeshow. At this event many vendors will make significant announcements, and perhaps it could be the most popular place for new machines to appear. Why didn’t 3D Systems wait another week to announce all this?

My suspicion is that they did need to counter the negative press they’ve received lately due to their surprising financial results. They need some good news, and these announcements are in fact, very good news – although they are a bit off into the future.

What this tells me is that 3D Systems is changing. We’ve already seen changes in their leadership, and now we’re seeing changes in their products and services. Change takes time, and sometimes not at the same time schedule as the market requires.

Via 3D Systems