A new material for 3D printers was announced today tells us something about the direction the filament industry is heading.

3D4Makers, a long time producer of 3D printer filament, partnered with Swedish plastics giant Perstorp to develop a new material they call Facilan, which has properties desirable for 3D printing.

For a 3D print filament company to partner with a chemical company is not a new phenomenon. This has been done several times, perhaps most notably by colorFabb with Eastman Chemical years ago. The results of such partnerships are always quite interesting and this case is certainly the same.

The new material is targeting common printing problems encountered by most, if not all, operators of plastic extrusion machines, including warping, layer adhesion and surface quality.

The first material released is Facilan C8, has a number of interesting properties according to 3D4Makers:

Facilan C8 is a new kind of 3D printing material. Developed to be a functional 3D printing material for manufacturing, C8 has been optimized for high throughput, high-reliability applications in 3D printing. Designed and developed for manufacturing applications Facilan C8 is the first of a family of Facilan materials that will cater to enterprise, engineering and industrial users of 3D printing.

- Higher impact strength than ABS.

- Higher tensile strength than ABS.

- Compostable.

- Easier to print than PLA.

- Luxuriously soft touch feel.

- Designed to be consumer friendly.

- Best layer adhesion properties and surface quality of any FDM material

Some of these characteristics sound a lot like PLA, and you’re probably thinking this is yet another PLA-variant that we’ve seen so often from other companies. But that does not seem to be the case here, as Facilan is apparently an entirely new thermoplastic that is not PLA.

I’m particularly interested in the surface finish on this product, as they say it produces “the smoothest surfaces of any FDM 3D printing material”. I’m not sure how they do this, but it may be that the material slumps slightly as it is extruded, making the layer boundaries more smooth. If this is the case, then you might be able to get away with less post processing.

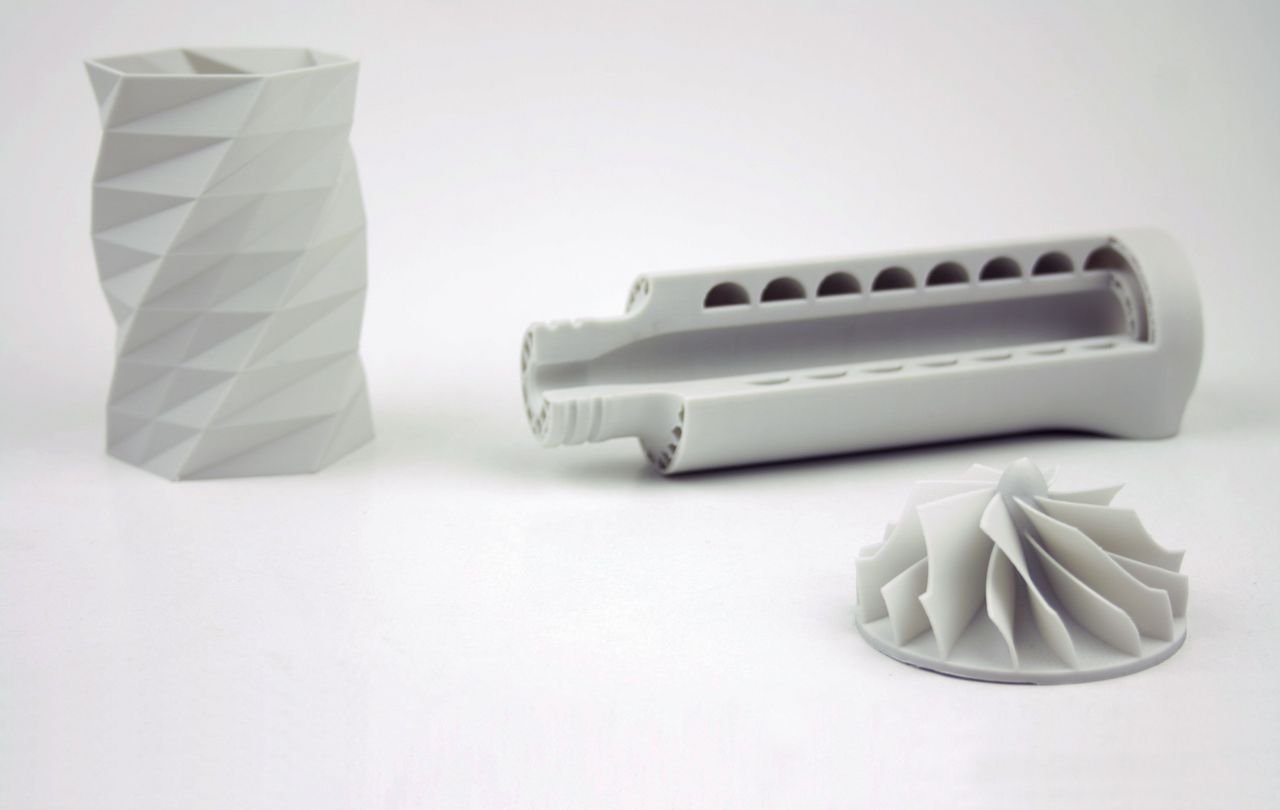

The sample prints shown at top and here do look quite good, but there’s nothing like doing a test yourself.

They don’t say much about the emissions produced by this material, but it does seem to have some excellent 3D printing characteristics.

I’m quite interested to give this material a test, and if you’d like to try it, 3D4Makers sells 750g spools for €39 (USD$45) in both diameters, 1.75 and 2.85mm. The materials are not shipping until this December, but you can pre-order them now.

But in a larger perspective, this announcement positions 3D4Makers among the relatively few 3D printer filament producers that is directly aligned with a proper chemical company. Others, like Verbatim, colorFabb, have the ability with their partnerships to create truly new materials never previously seen in the 3D printing world. Those new materials will most certainly exhibit incredible properties that will attract prototype makers and grow the professional desktop 3D printing market.

And that, to me, is the future of 3D print materials: a transformation into far more varied and sophisticated products, with something to address every need.

Via 3D4Makers