BASF is making more moves into 3D print space.

BASF, the chemical giant, has been making a few more moves to build up their 3D print expertise, which was already growing. Previously we wrote on their move this summer to set up a subsidiary specifically addressing the 3D print market.

That subsidiary, BASF 3D Printing Solutions GmbH, is only a month old, but things are happening.

This is from an almost invisible start. At trade shows we slowly began to see mention of them more frequently, whereas in past years we hadn’t seen them at all. They were mentioned by some vendors as a partner is various projects, but were not seen directly.

Then the announcement of the new subsidiary made all this very clear: BASF is targeting the 3D print market and pursuing it aggressively. Perhaps they’ve seen their competitor Mitsubishi / Verbatim doing well and want a piece of the action? Maybe they see a bright future in 3D printing with the dramatically increasing sales of professional 3D printers, all of which will require powerful, quality thermoplastic materials to be of best use?

I don’t know, but here’s what I do know: they have taken two more steps lately.

One is the acquisition of a polyamide manufacturing service. They explain:

BASF and Solvay have signed an agreement related to the sale of Solvay’s integrated polyamide business to BASF. The purchase price on a cash and debt-free basis would be €1.6 billion. According to applicable laws, the intended transaction is subject to consultations with the relevant social bodies of Solvay, following which both companies will enter a binding purchase agreement. Solvay and BASF aim to close the transaction in the third quarter of 2018, after customary regulatory approvals have been obtained and the formal consent of a joint venture partner has been received.

So now (or at least after this deal closes) BASF will strongly complement BASF’s engineering plastics catalog for a variety of manufacturing purposes.

Including 3D printing, where polyamide is a very popular material for powder-based SLS systems used worldwide.

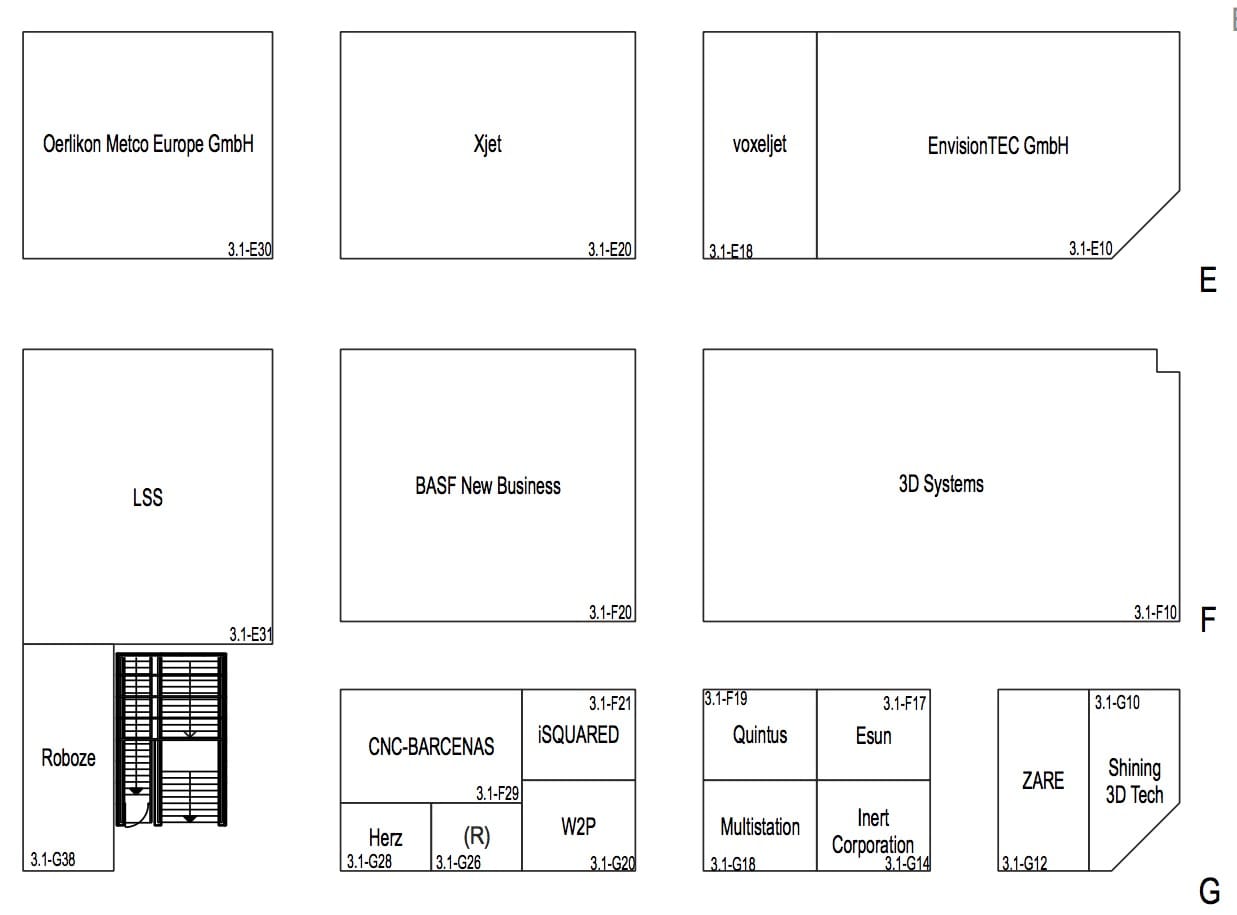

The second item I noticed was something a bit more subtle, at least until November. Check out this floor plan for the upcoming FormNext 3D print show taking place in Frankfurt this fall:

Yes, that’s a BASF exhibition stand, the first we’ve ever seen scheduled for a major 3D print trade show. Notice that it is the same floor size as LPW across the aisle, a notable manufacturer of metal powder. And the BASF stand is half the size of 3D Systems! Clearly they are pouring a significant amount of money into their 3D print venture.

It seems their slogan, “We Create Chemistry”, might be changed to “We Create Chemistry For 3D Printing”.

Via BASF