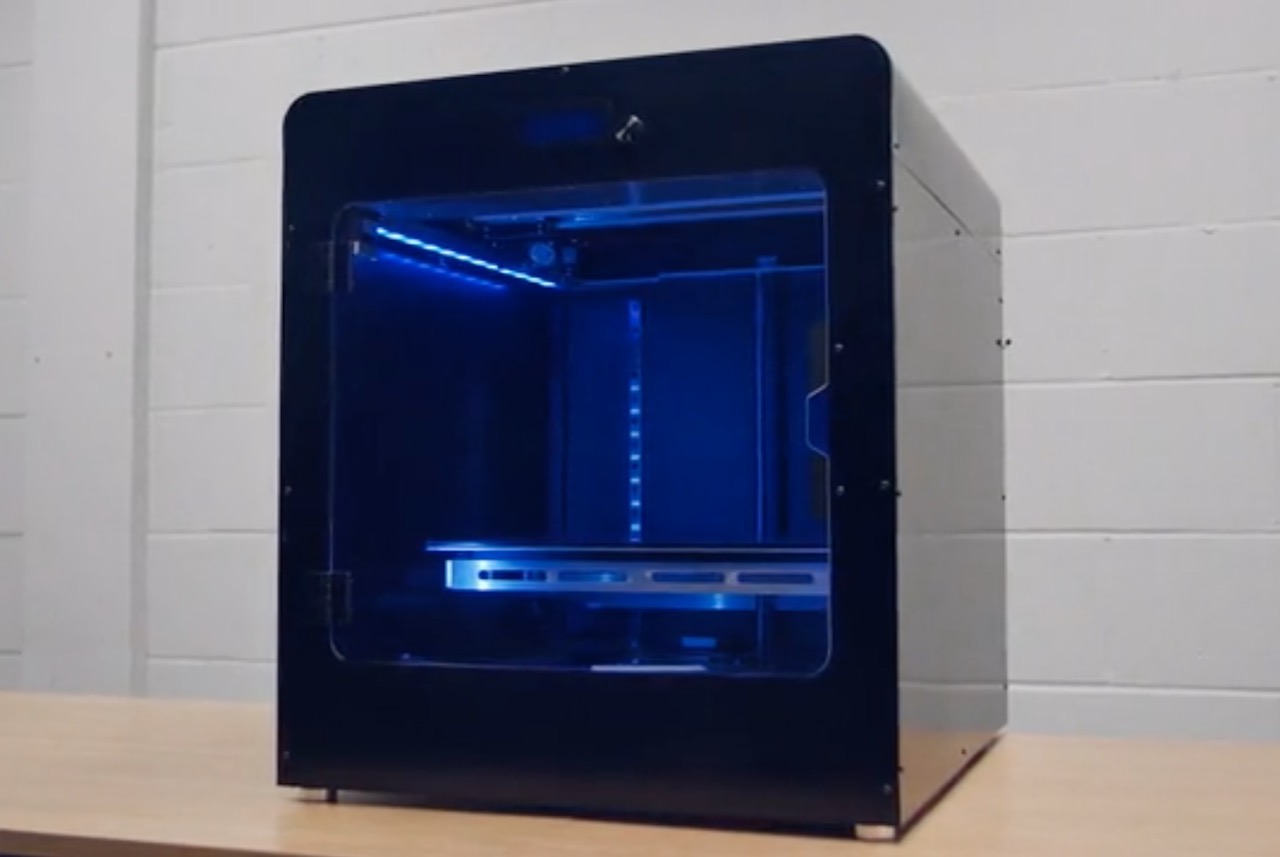

Another interesting professional desktop 3D printer option has launched: the Inception X1.

Developed by UK-based Inception Machines, the X1 has a lot of features that should attract professionals seeking a desktop prototyping machine. And it’s size to price ratio is extremely good, too.

Let’s talk about the size of this machine first. The build volume is a very healthy 340 x 340 x 340. That’s one third of a meter on all sides, and should be able to handle any 3D print that you’re likely to contemplate.

However, large prints do run the risk of warping, and Inception Machines has mitigated this by providing a completely enclosed, heated chamber. This keeps the printing environment at a consistent high temperature that minimizes the warp effect, which is quite noticeable in certain thermoplastics at the large sizes this machine is capable of printing.

The X1 is also made from CNC milled aluminum, so it should be quite solid and significantly reduce quality issues caused by vibrations.

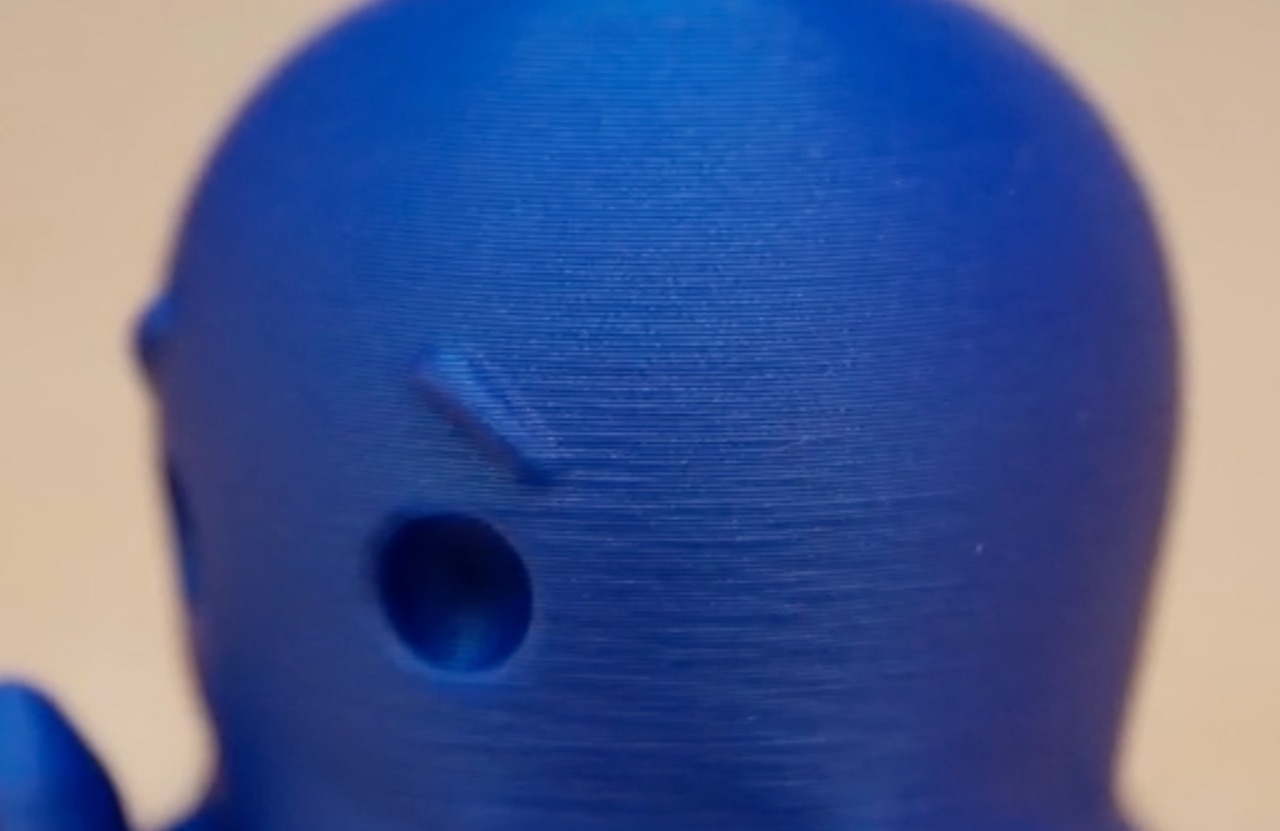

The precision of this machine is also very good. They boast of the ability to 3D print layers as small as 0.02mm, smaller than the typical machine’s 0.10mm and even smaller than more advanced machines that top out at 0.05mm layers. Of course, you will have to use a smaller nozzle size to achieve this, but that’s again one of the features of this machine: it comes with interchangeable nozzles from 0.2mm for finer details and up to 0.8mm for large, high speed prints.

The hot end on the X1 can hit 300C, meaning this machine can 3D print all of the common engineering materials such as ABS, Nylon, PETG, and Polycarbonate. However, its temperature is too low to 3D print more exotic materials like PEEK or ULTEM.

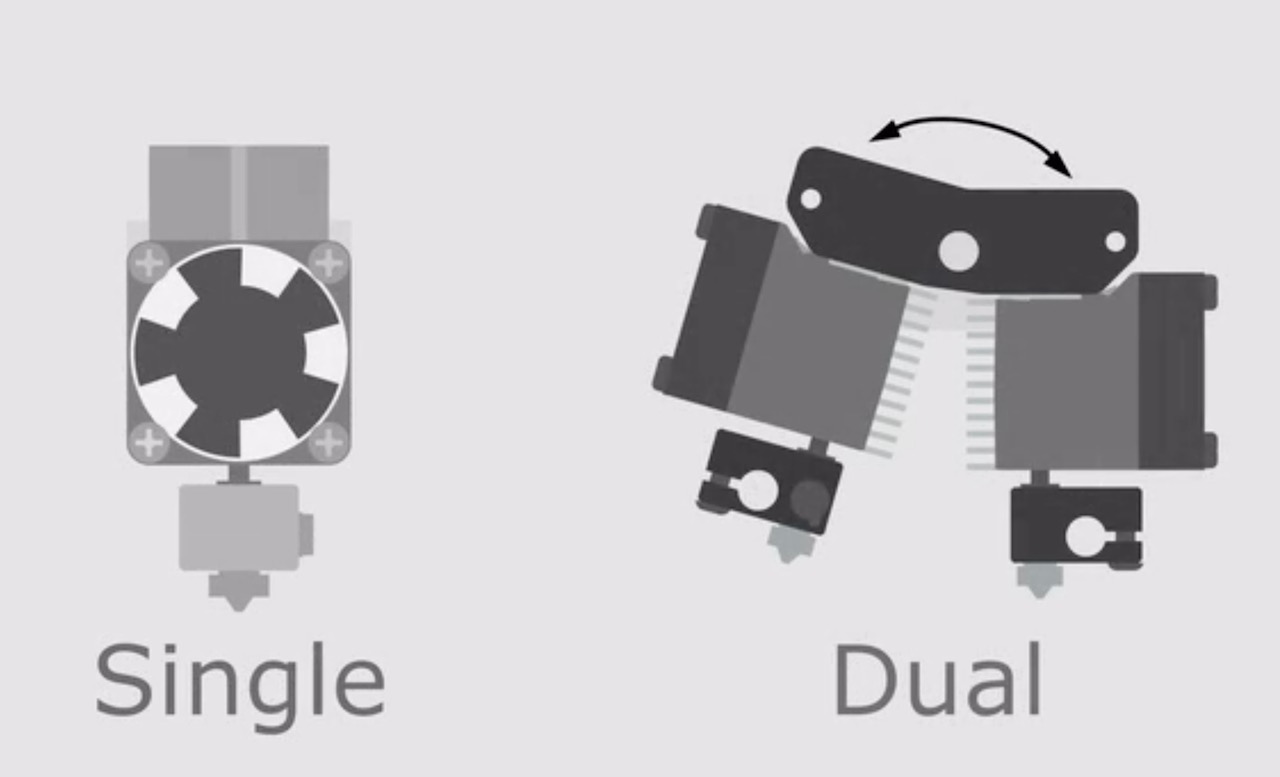

Most professional desktop 3D printers these days include the ability to 3D print in more than one material, specifically to enable the use of soluble support material. This capability means you can freely 3D print almost any geometry and be guaranteed it will work correctly.

But the interesting thing here is how Inception Machines implemented the dual material feature. Instead of providing two parallel hot ends and extruders, or the single nozzle – two extruder approach used by almost all other entrants, they opted for an unusual “tilt” system.

Here’s how it works: when the GCODE wants to switch materials, the system tilts the current extruder away from the print point and swings in the alternate nozzle. This is done quite quickly, and avoids the complications of both other approaches.

The swing motion takes the out-of-action nozzle far away from the print so it almost never interferes with the print. This is what caused most difficulties with the parallel extruder approach, as even the slightly bit of material poking up above the print plane could catch on the moving extruder.

It also eliminates the single nozzle approach’s problem of purging out the “other” material before engaging. While the single nozzle approach is simple, it does take longer due to the requirement for purging on every material switch.

There are two models of X1 available, one with, and one without, the tilting nozzle. In other words, single or dual material.

Software for the X1 is the usual open source suite of Cura, Slic3r, etc. It seems there is no dedicated software for this equipment.

For their launch, they’ve priced these each at £1,595 and £1,795 (USD$2,100 and USD$2,370 respectively). That’s a pretty decent price for a machine of this size and capability.

What I find quite interesting about this device is that it seems very close to Stratasys’ well known uPrint device. That very popular machine uses a heated build chamber (although directly heated), and has a tilt extruder as well – but one that uses a single nozzle.

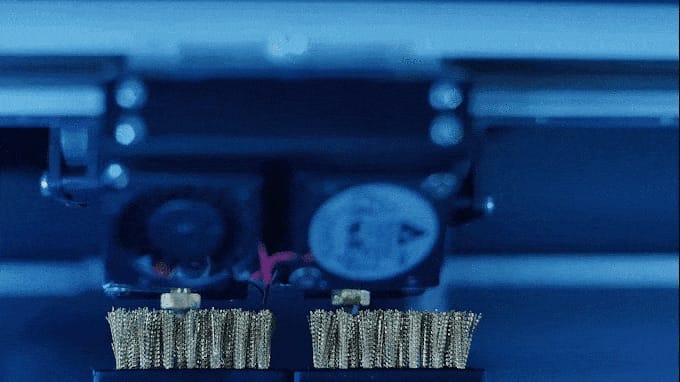

And then there’s this: a metal toothbrush head-style nozzle cleaner, which is used to get rid of drips. This is precisely what you’ll find inside a uPrint.

But of course, the uPrint costs a lot more.

And this machine is entirely open source; you could build one yourself if you like. The design, created in Autodesk Fusion 360, is apparently available, but I could not find a link for the files.

Finally, our usual word of caution regarding buying a 3D printer from a startup company. This is not without risk, but you cannot know whether the product or provider will succeed and survive. Please review our crowdfunding checklist before proceeding.

Via Kickstarter and Inception Machines