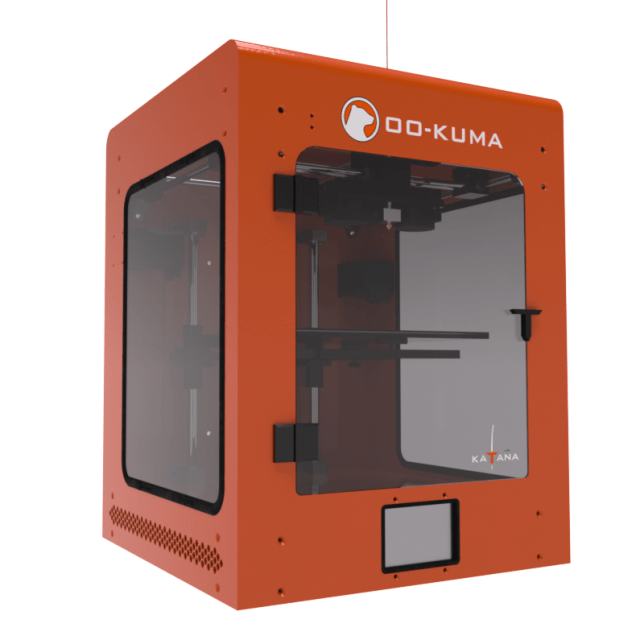

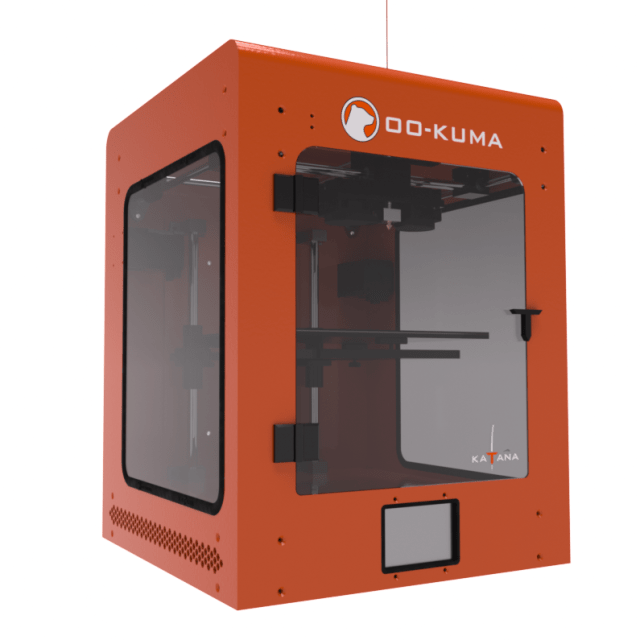

There are a growing number of what I like to call “professional” desktop 3D printers emerging recently and one of interest is the Katana from OO-KUMA.

I hadn’t heard of OO-KUMA previously, but it is a Turkish company based in Istanbul. The company also produces a desktop SLA 3D printer, and has a larger-format filament extrusion 3D printer in the works for release later this year.

But today I’m interested in the KATANA. which has a surprising number of useful features. I mentioned this is a “professional” desktop 3D printer, and in my mind that means it is capable of handling a wider variety of engineering materials, with higher quality and on a reliable basis. Those characteristics appear to be the case for this device.

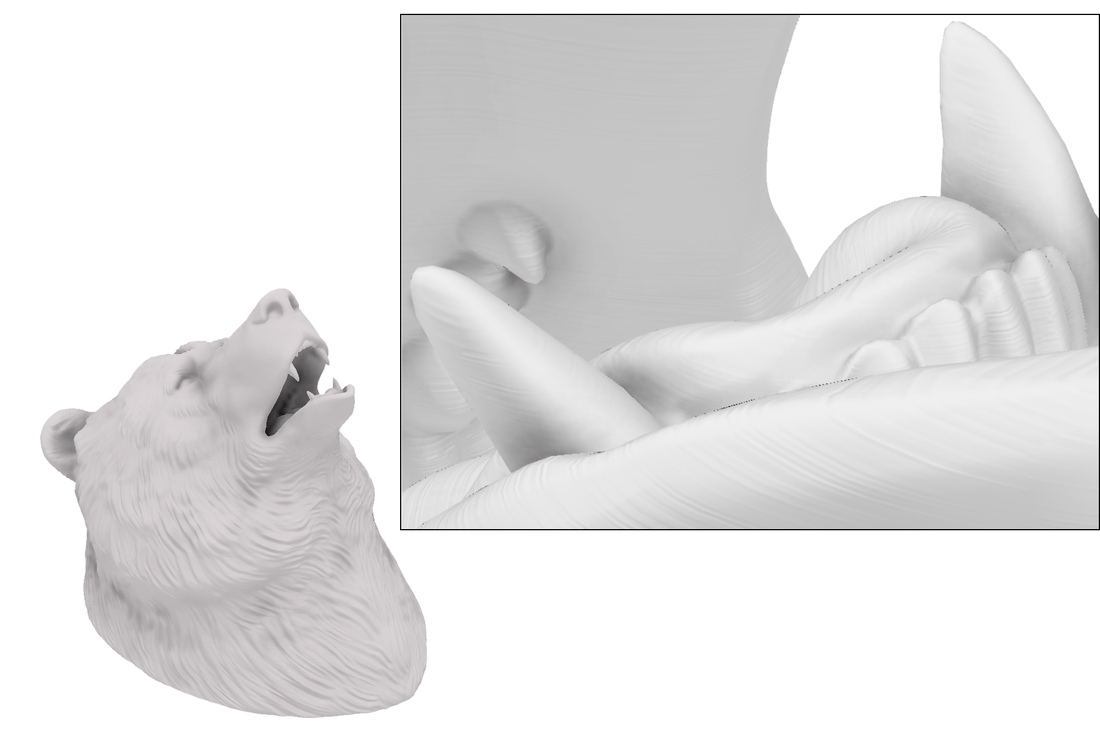

The build volume on this machine is a standard 200 x 200 x 185mm, neither large nor small. But what is of interest is that it is capable of 3D printing layers as small as 0.02mm, about half the size of most other desktop units. That should provide for very smooth surfaces, although the print time will proportionally increase.

The thermal system is quite powerful. Within it’s enclosed build chamber, the KATANA’s hot end can hit a very high 480C! That should be able to handle virtually any filament-based material you can throw at this machine.

The hot end nozzles are made from Titanium-Molybdenum-Zirconium alloys, making them able to handle very abrasive materials including carbon fiber and metal-infused thermoplastics.

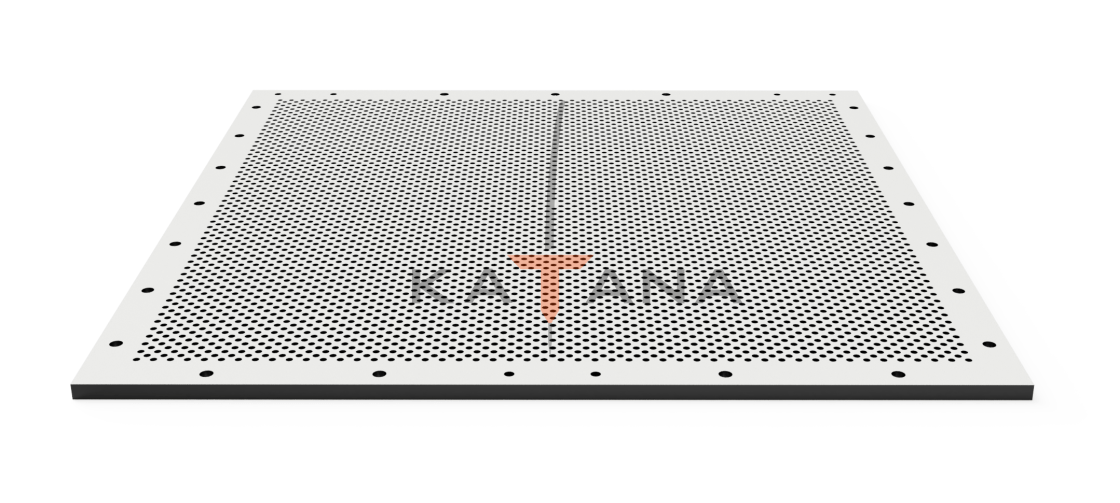

The print surface can be set to as high as 120C, a bit higher than typical print surface temperatures. The print surface, by the way, is a unique design. They explain:

Thanks to the printing surface coating with the international patent, all OO-FABRIC materials can be easily reprinted without needing any additional application. It is permanent, maintains its property indefinitely, and does not incur additional expense.

Almost all desktop 3D printer systems have a consumable print bed that must be periodically replaced. But this one is apparently permanent. The design is interesting in that it incorporates a number of holes that likely moderate the amount of adhesion.

The KATANA’s exterior case is said to be made from “aviation alloys”, making it solid. The company says you can expect “thousands of hours” of use on this device.

KATANA’s user interface is a proper color touch screen, and the system also includes a WiFi connection for remote operation. The company claims it requires “no operator” due to the presence of numerous sensors, but I suspect you still need someone to at least load the filament and unload the prints.

They also offer a very complete set of thermoplastic filaments, although you are certainly able to use any third party filament as well. Their list of supported and for sale materials includes: Performance ABS, Tough PLA, Extreme PET-G, True FLEX, Superior HIPS, Ultimate PA12, High Strength PC, Carbon-Fiber ABS, CF0, Carbon-Fiber PA, CF1 , Carbon-Fiber PEEK, CF2, High Temperature 220, Medical Grade, MG0, Bio-L, MG1, ULTEM, PEEK, and a Cleaning & Maintenance material. (Note that CF1, CF2, ULTEM and PEEK are not available until the end of the year, however.)

Does the machine work? Well, the offer some images of exceptionally well done 3D prints, so it seems it does.

All of this sounds very good, but what does this unit cost? They list it as TRY9,900, which is equivalent to only USD$2900! As well, their site says “free shipping, worldwide”, making this an exceptional deal for a professional desktop 3D printer. And get this, they also have a 5% off deal until end of September, making you save another USD$100 or so.

Via OO-KUMA