There’s a very common problem encountered with desktop 3D printers: spool size mis-match.

Every machine is designed with a particular spool size in mind, with a specific outer diameter, inner hub diameter and width. Usually the 3D printer manufacturer partners with a particular filament provider and uses their specifications.

This works very well, so long as you continue buying spools from that filament provider, which in some cases can be the 3D printer manufacturer themselves. The spools fit perfectly on the mounting mechanism, and freely revolve to smoothly deliver filament to the extruder.

But then, you realize your 3D printer is capable of “open materials”, meaning you can buy filament spools from other providers. This offers the possibility of diversifying your material types and colors, as well as the likely possibility of lowering your operating costs. Third party filament providers often provide either lower cost standard materials, or higher priced exotic materials, offering unusual properties.

It’s very often attractive to use alternative materials for cost or function, but what happens when the spool doesn’t fit?

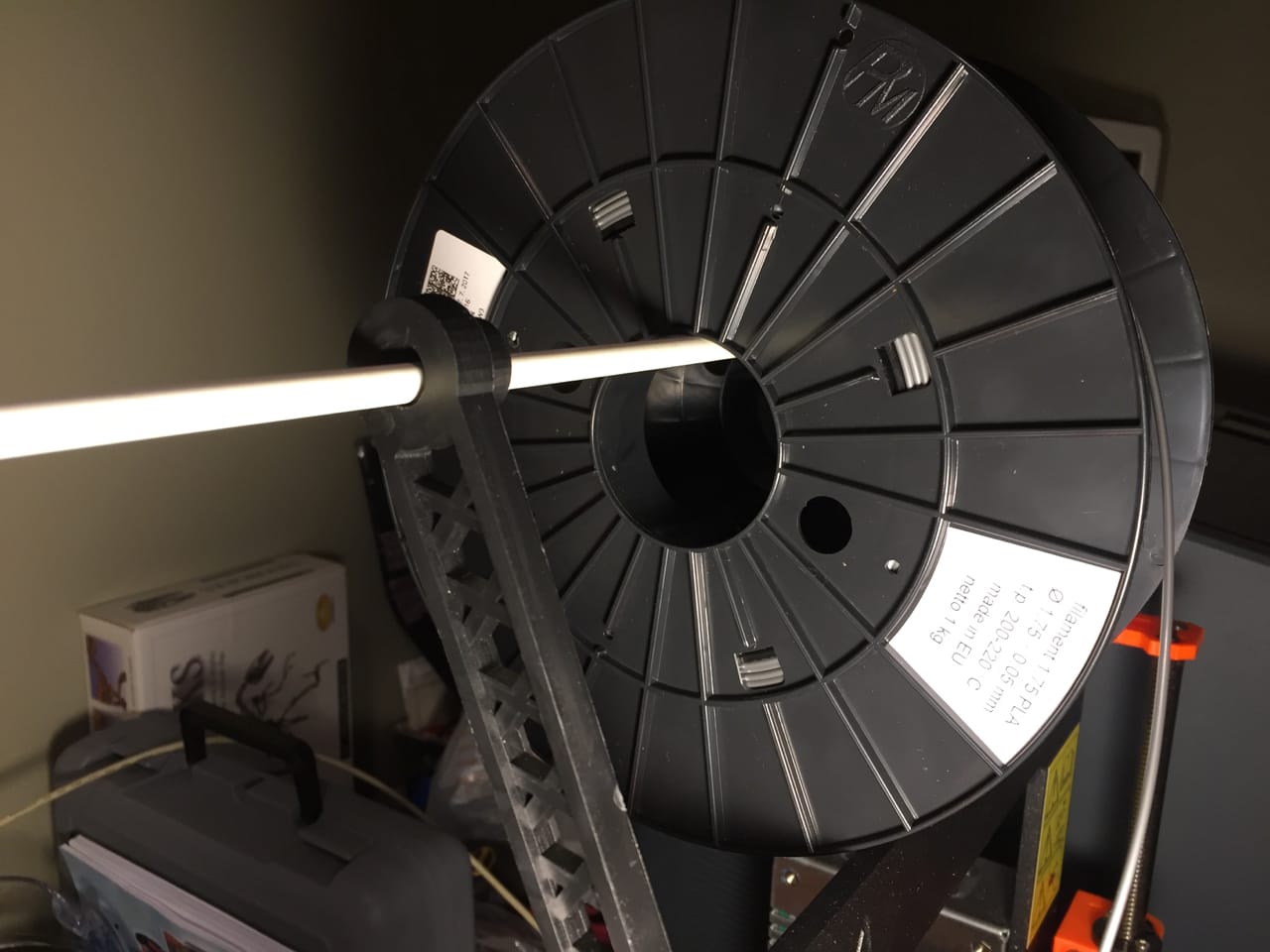

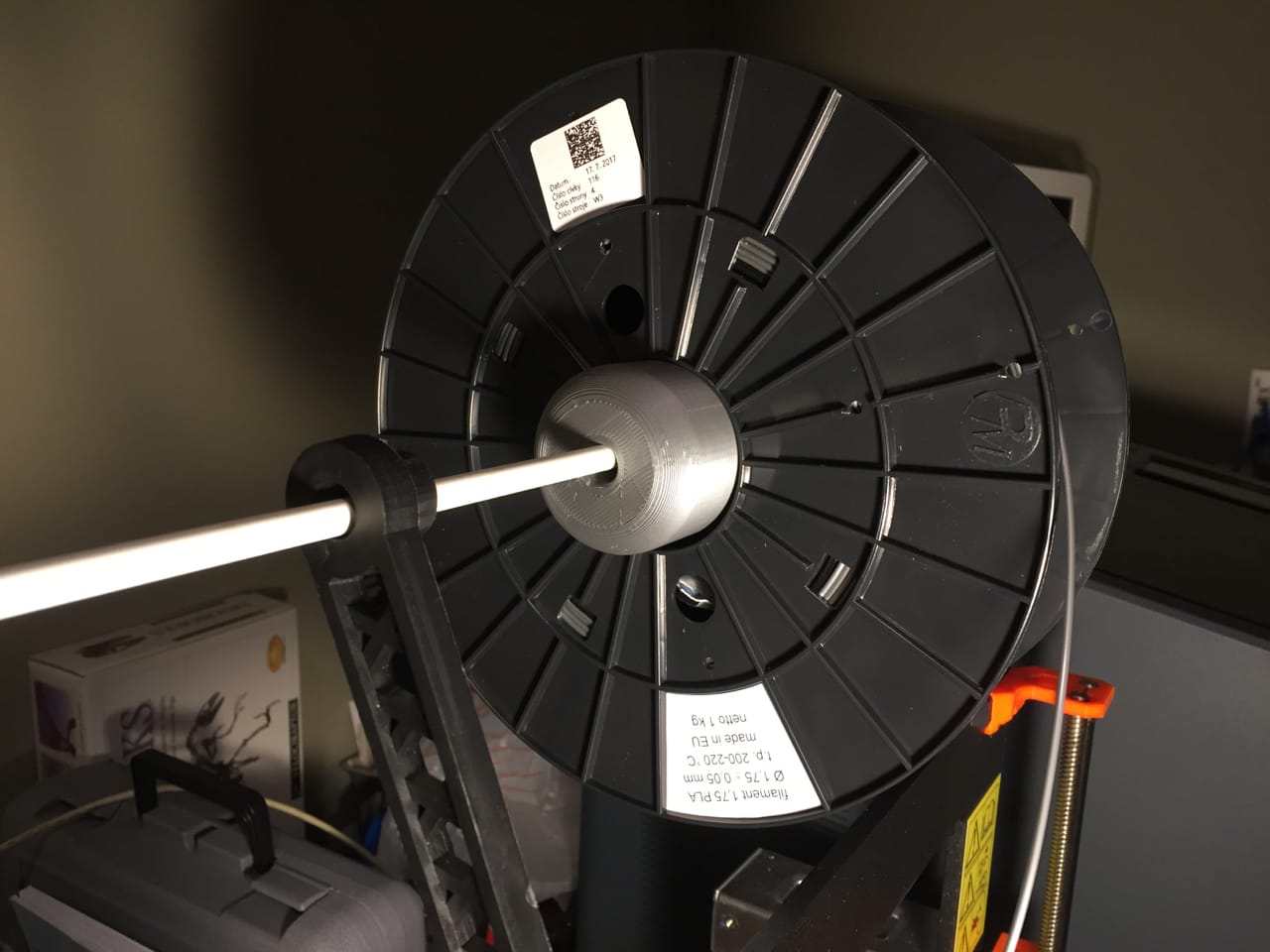

Sometimes the problem is relatively easy to resolve. Consider the case shown here, where a standard Prusa i3 MK2 is having challenges with a third party spool because the inner hub diameter is larger than expected. The spool then lies lower than planned and actually bumps into the top part of the machine, preventing it from rotating freely.

The solution is straightforward: 3D print a couple of hub adapters that close the hub gap as shown here.

However, sometimes the problems are far more difficult.

Some machines offer a somewhat constrained area for holding the spool, like the BEETHEFIRST desktop 3D printer. To make this work, you’d have to find a spool that’s just the right size to fit between the top and bottom. You’d more than likely just buy directly from BEEVERYCREATIVE rather than doing an extensive search for alternative materials.

Now consider the case of a machine with an internal bay for the spool, such as the MakerBot Replicator+. In this case, the spool must fit or else it just won’t work. I suspect this is a subtle way for MakerBot to encourage buyers to continue purchasing MakerBot supplies, even though the machine is technically capable of open materials.

For these situations, a very practical solution is an external spool mount. The good news is that there are plenty of them to choose from, some complex and some very simple. In fact, a recent search of Thingiverse revealed no less than 4,869 different spool holder entries! Many can be 3D printed, but some also suggest simply using a common lazy-susan rotating platform.

The only catch is that the path from the external mount to the 3D printer’s extruder must be clear and not particularly lengthy. If the filament is grinding against some object along the way, that’s not good.

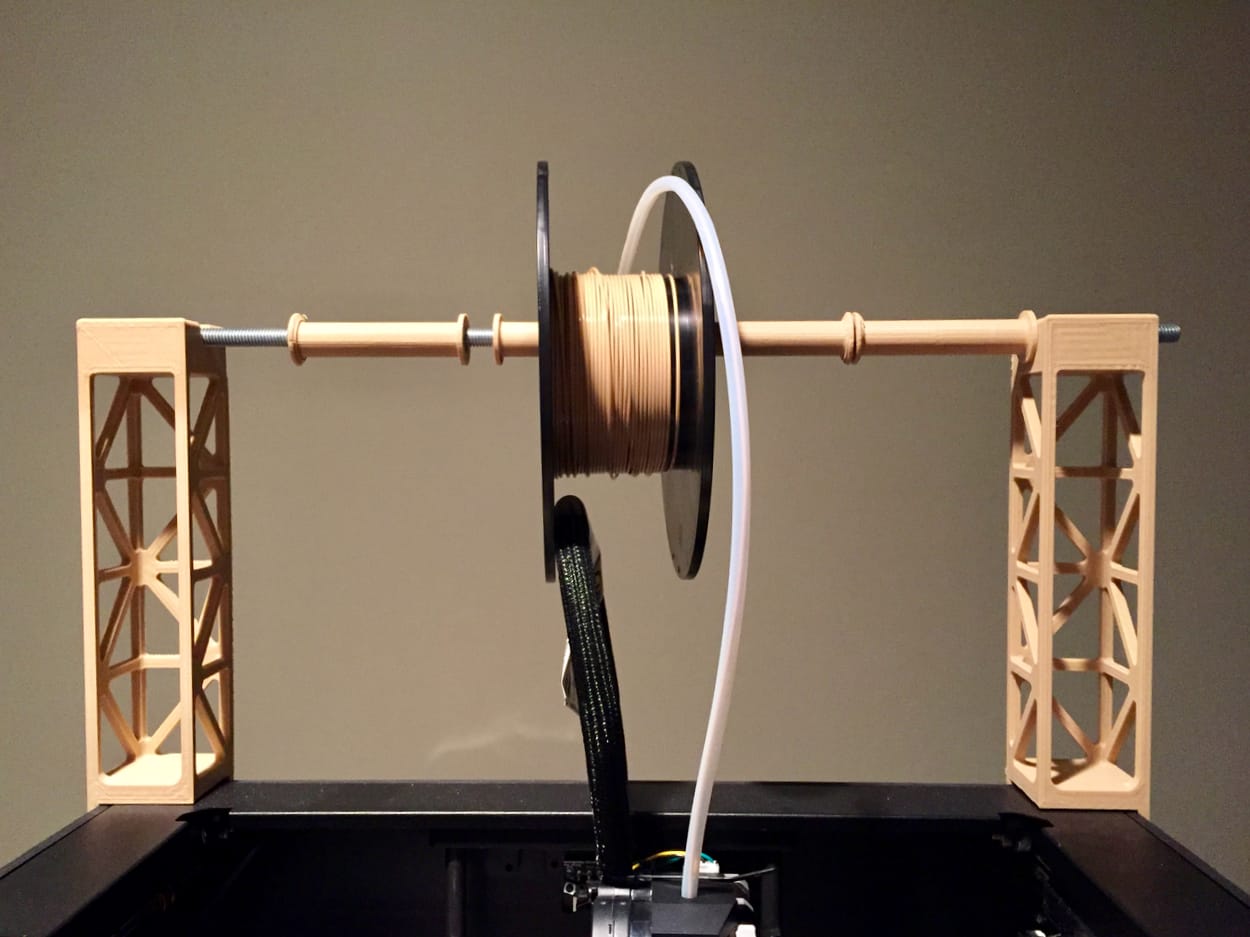

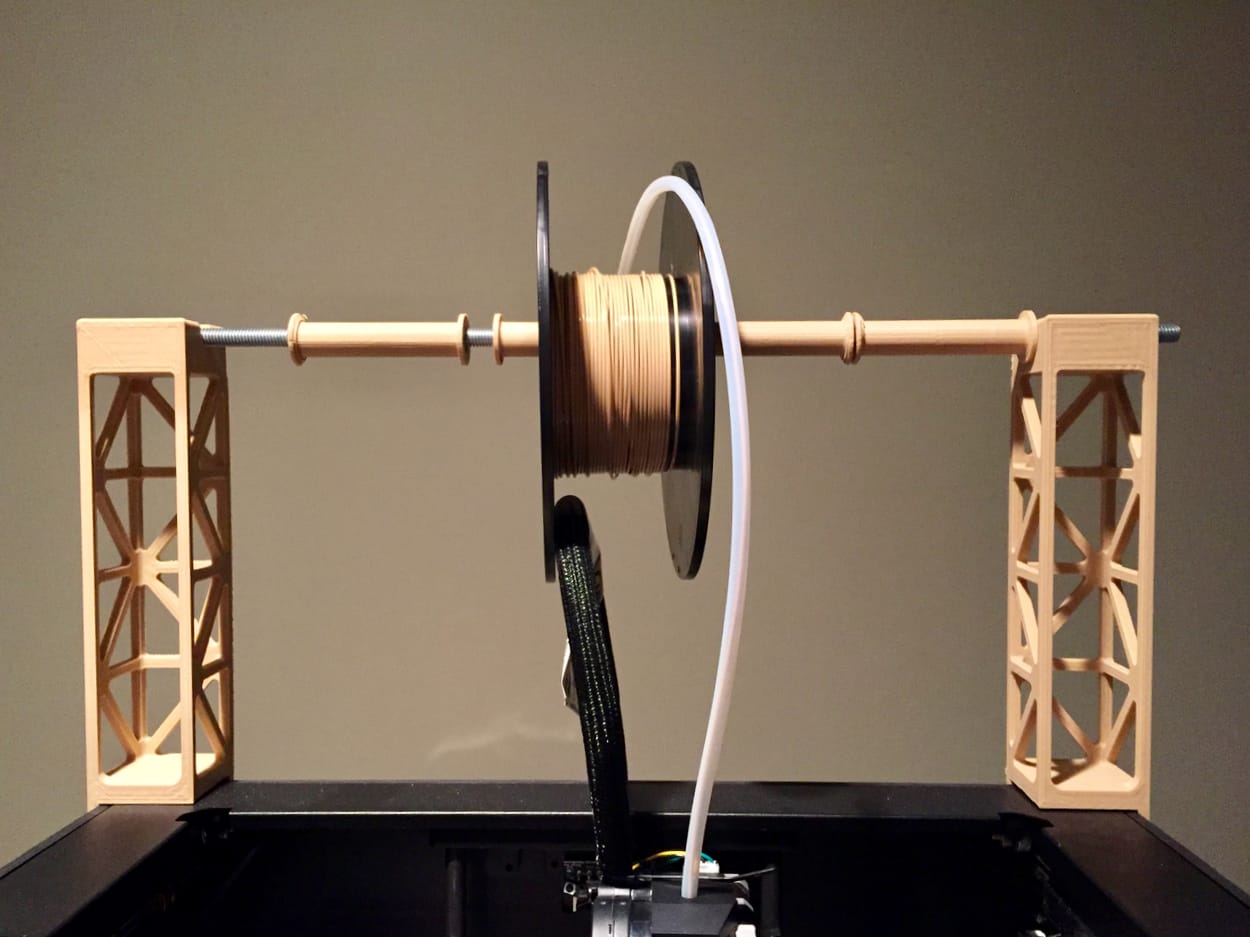

My preferred method is to hang the spool above the 3D printer in some fashion. Sometimes this is a simple affair by nailing up a rod to the surrounding structures. But other times you can mate the “hanger” to the machine, as shown at top.

What’s your favorite spool size solution?