After making a splash and swimming around a bit with its Multi Jet Fusion (MJF) 3D printing technology, HP is now stepping into the custom footwear race with a new 3D scanning solution dubbed the FitStation.

Once the FitStation is used to create custom insoles, these orthotics are then 3D printed with MJF.

HP isn’t racing alone in the custom footwear market. Multiple large manufacturers, such as Nike and Adidas, are 3D printing shoe soles, while a number of startups, including Feetz and Wiiv Wearables, are working on products ranging from 3D-printed shoes to sandals.

What’s HP’s position in the race? Let’s look at how HP compares to its competitors.

HP

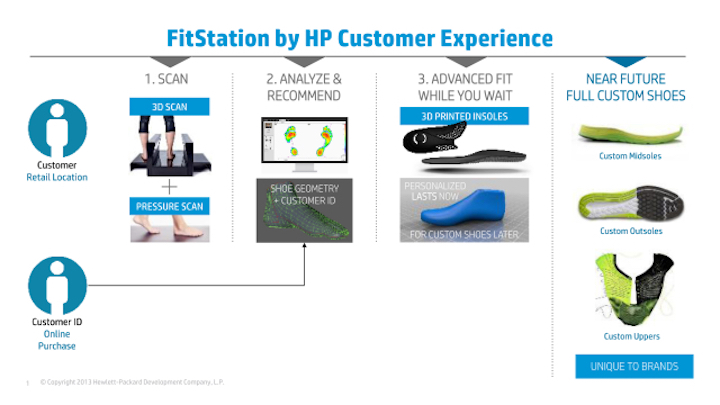

HP’s FitStation is a hardware and software platform that first 3D scans a person’s foot, measures foot pressure and performs gait analysis to create a “digital profile” of each foot. This makes it possible to then 3D print insoles and create custom footwear. The footwear can then be 3D printed on HP’s MJF platform.

The FitStation setup from Superfeet in one retail location. (Image courtesy of HP.)

The solution will be deployed at 4,000 retail locations through Superfeet, an over-the-counter insoles company. Additionally, safety shoe manufacturer Steitz Secura will use the FitStation for its comfort, preventive health and safety operations.

SOLS

Among the first companies to hit the track was SOLS, a New York-based startup that produces custom insoles created through photogrammetric algorithms that convert photos taken of feet with a smartphone app. These orthotics are then 3D printed from nylon using selective laser sintering (SLS).

Though it was early in the game, SOLS laid off 20 percent of its staff in January 2016 and was ultimately acquired by Aetrex Worldwide, another custom orthotics and shoe manufacturer, in March 2017. Aetrex, based in New Jersey, is using the acquisition to complement its own foot scanning technology. However, if you look at the company’s social media presence, you’ll see that nothing much has been posted since June 2017.

Wiivv Wearables

Wiivv is newer to the track, but has proven successful after launching what was at one time considered the most successful 3D-printed product on Kickstarter, also a 3D-printed insole created through photogrammetry and a smartphone app. Like SOLS insoles, Wiivv’s wearables are 3D printed with SLS.

Wiivv’s sandals feature 3D-printed arches. (Image courtesy of Wiivv Wearables.)

Wiivv has since leapt forward to 3D-printed sandals. At about the same time that SOLS was being purchased by Aetrex, Wiivv was launching its 3D printed sandal line on Kickstarter, which also was successfully funded at over $500,000.

Feetz

Feetz is a unique case in that the San Diego-based startup is 3D printing complete shoes. Like the aforementioned products, sizing is determined through photogrammetry and a smartphone app. The shoe is then 3D printed on fused filament fabrication (FFF) 3D printers using recycled material. Once a wearer wants to throw out the pair, they can send them back to the company, which recycles the material for subsequent shoes. According to the company, Feetz “products require zero water, are made using recycled and recyclable materials, reducing our carbon footprint by 60%.

Feetz uses 3D printing to create everything from the midsole to the upper. (Image courtesy of Feetz.)

In Fall 2016, Feetz partnered with shoe retailer DWS to produce custom shoes at pop-up locations in DSW’s NYC 34th St and SF Union square locations. More recently, the startup worked with two-time Project Runway winner Seth Aaron to launch the first 3D-printed designer shoe line at FashioNXT Week this fall.

Read more at ENGINEERING.com